Plants need a strong pipeline of data to help them ensure optimal performance. We spend a lot of time talking about how to collate, transmit, and store that data so it is easily accessible whenever and wherever people need it. However, all that strategizing is of...

Posts by or with Drew Mackley

Four Best Practices for Condition Monitoring

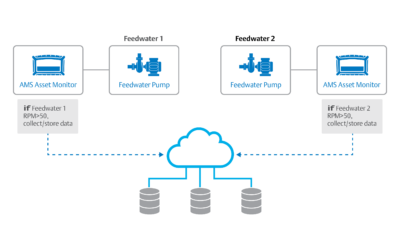

It is easier than ever to store massive amounts of data. The cost of wireless sensing technologies has dropped dramatically, making it much easier to instrument every asset in the plant and ensure that no performance aberration goes unnoticed. However, bringing in all...

Three Strategies to Drive Improved Reliability

A rapid decrease in the cost of sensing equipment has driven many reliability teams to implement even more automated condition monitoring across their facilities. A wide variety of new technologies are both easy to implement and full of robust features to increase...

Make the most of your reliability workforce

Today’s plants frequently have limited personnel but still need to find ways to do more work and meet increasing goals and quotas. This dichotomy frequently causes a problem when it comes to asset monitoring, which is traditionally performed by technicians manually...

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.