Today’s shortage of experienced plant personnel comes as no surprise to anyone. But the optimal solution to that problem might be a bit less obvious than the problem itself. Those retiring workers aren’t coming back any time soon, but plants still need to find ways to close the expertise gap until they do.

Today’s shortage of experienced plant personnel comes as no surprise to anyone. But the optimal solution to that problem might be a bit less obvious than the problem itself. Those retiring workers aren’t coming back any time soon, but plants still need to find ways to close the expertise gap until they do.

The solution—wireless data collection and analysis—has been available for many years. Today’s automation marketplace offers a wide variety of cost-effective wireless sensors that are easy to install, yet powerful enough to help plant personnel make better decisions about the health of plant assets, regardless of their experience level.

Digitally empowered personnel perform better

Maintaining a strict schedule of manual rounds typically requires a deep bench of experienced personnel. Not only do the people performing the rounds need the open schedules necessary to do the time consuming work of inspecting each asset with a handheld device, but they also need the experience to be able to do it safely, and to know what they are seeing on the analyzer.

Instead of tying up limited personnel on the low value task of walking around the plant checking assets, today’s most effective reliability teams are instead using intelligent wireless technologies to collect and deliver asset health data directly and automatically to the control room and their smart devices. Wireless devices like Emerson’s AMS Asset Monitor not only collect and report asset health data in real time, but also include built-in edge analytics, to help quickly and easily identify the most common problems with

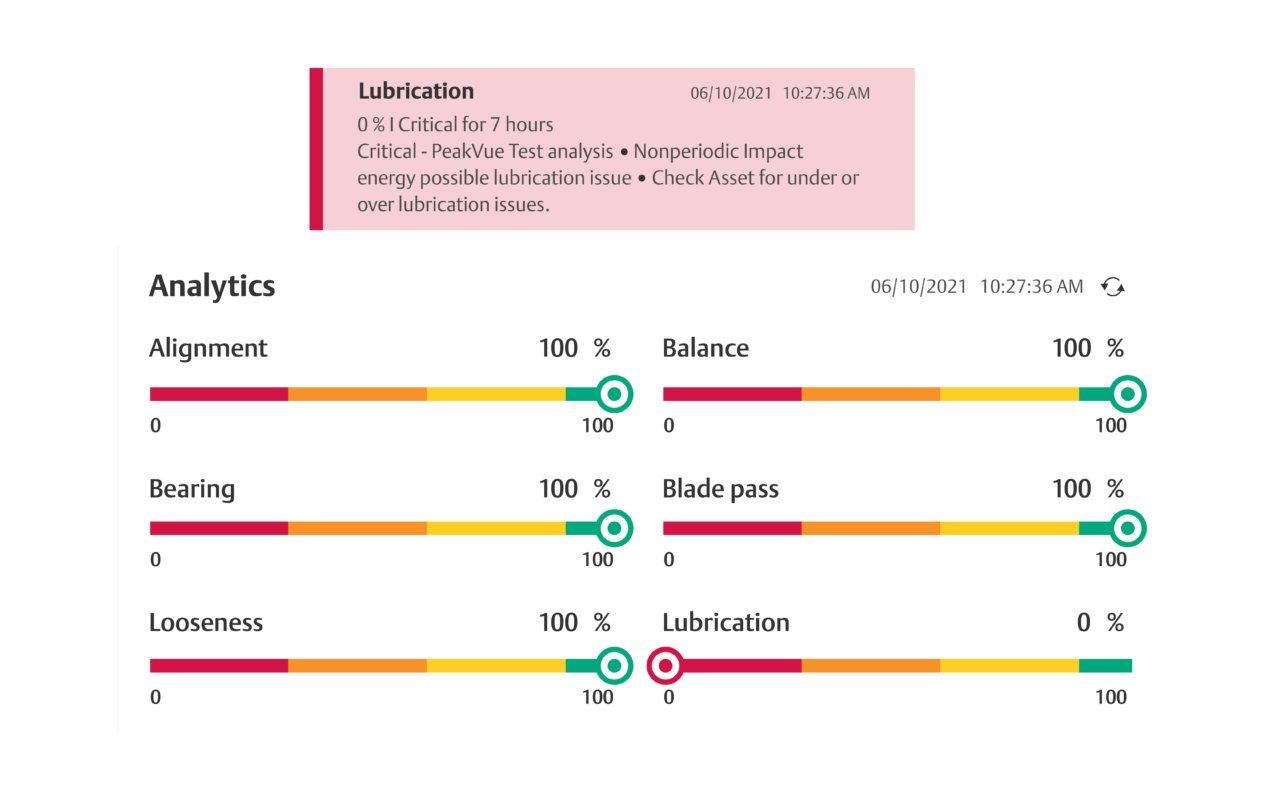

Intuitive analytics make it easy for any technician to identify failing equipment and take action.

rotating assets.

This edge analytics technology is a critical upskilling tool for less experienced reliability personnel. Properly reading spectrum and waveform data from tools such as a basic handheld analyzer can take years of practice. In fact, a new technician typically needs two to three years of experience before analyzing raw data to identify root cause becomes second nature.

Providing intuitive analytics data to reliability personnel makes it easier for them to quickly isolate, identify, and solve problems, making it far less likely that teams will experience unplanned outages. Powerful tools like Emerson’s PeakVue™ technology provide equipment health status by color—green, yellow, or red based on the severity of the issue. Technicians can tell in moments whether an asset needs service and can quickly and easily prioritize when there are multiple issues.

Focus on unplanned outages

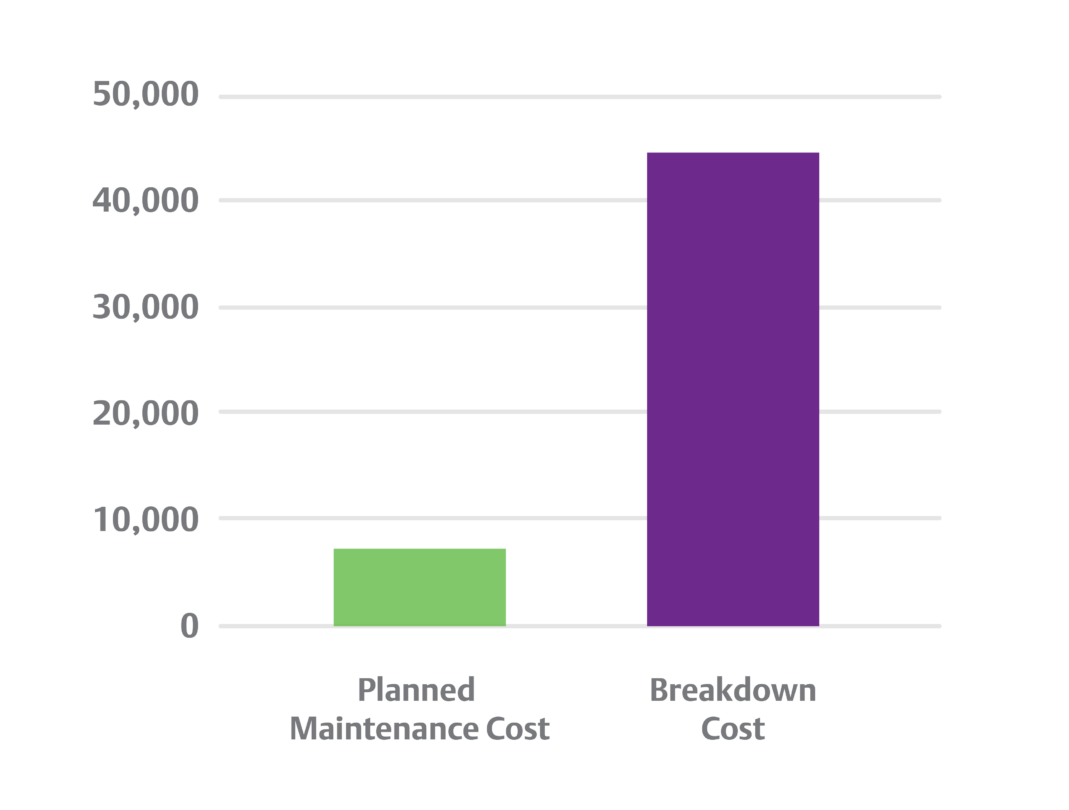

Unplanned outages typically result from equipment breakdowns. Emerson estimates breakdowns generate five to ten times the repair cost of planned maintenance, not including revenue loss. Moreover, when a facility or process line is down for repair, the company also experiences opportunity loss. When a product isn’t available on the shelves, competitors gain the opportunity to increase their market share.

Equipment breakdowns cost five to ten times more than predictive maintenance.

Reliability teams armed with digital tools to predict, analyze, and prevent equipment failures are a plant’s best defense against unplanned outages. When personnel can quickly and easily identify impending failure, they can intervene before a small problem leads to a breakdown. They can also plan their maintenance windows more effectively, scheduling the right equipment for repair and ensuring they have the right parts and tools on hand to restore an asset to full health.

Work with a trusted partner

Emerson sensing technologies are designed to make it fast and easy for teams to identify problems and resolve them, regardless of experience level. Emerson’s AMS Wireless Vibration Monitor, AMS Asset Monitor, and AMS Machine Works software all work in tandem to provide a holistic view of plant health and help reliability teams intervene before small problems become equipment failures.

To learn more about how to implement digital technologies to upskill reliability personnel, including real-world examples of digital reliability technologies in action, read “Wireless Data Collection: Stop Chasing Reliability Data” in Chemical Engineering Magazine.