Few process manufacturing teams today are struggling with having too little data. On the contrary, many organizations are overwhelmed by the massive amounts of data streaming in every day from their field devices and collected during scheduled rounds. Much of that data is useful if it can be analyzed. But in today’s environment of worker shortages leading to lean staffing, few organizations have the deep bench of experienced personnel necessary to ensure data is properly collected, collated, organized, and analyzed in a timely manner.

The solution, Emerson’s Erik Lindhjem posits in a recent article in Processing magazine, is enterprise level asset management software. Such tools bring together large collections of data and automatically standardize and contextualize it before delivering it to the right users—wherever they may be. This seamless delivery of contextualized data is a critical foundation of Emerson’s Boundless Automation™ journey, using cutting edge technology to drive data seamlessly from the field through the edge and into the cloud.

Busy people need better tools

Between asset management systems, machinery health software, and third-party systems, large process manufacturing facilities have many disparate systems collecting critical data. If the systems aren’t seamlessly connected, someone must take the time to log into each system to collect data, move it where it needs to go, and keep track of the process using cumbersome tools like spreadsheets. Such a process not only takes hours but is also unreliable. If the person responsible for data is out of the office, the task likely won’t be completed, creating a backlog of data management.

Enterprise level asset management software makes it easy to ensure data is collected regularly and reliably, without interrupting the other tasks personnel on a lean team may be responsible for. Erik explains,

“A centralized team can use enterprise asset management software to collate data from every critical data source via modern, open protocols like OPC UA and MQTT. These types of systems deliver critical data to a centralized solution at the enterprise level, where it is standardized, contextualized, and distributed to the right users in real time. A core group of experienced personnel at the enterprise level can then quickly track, trend, and monitor the health and performance of every asset in the fleet.”

Simplifying the schema

After a plant has operated for many years, the difference between what is recorded in documentation and software and what actually exists in the field begins to grow. This disparity is called data drift, and can make it particularly difficult for teams to get a handle on their plant or enterprise health. Over time, as teams add new equipment but do not necessarily follow a set of standards, they can create a complex web of assets, making it hard to isolate and identify the source of problems.

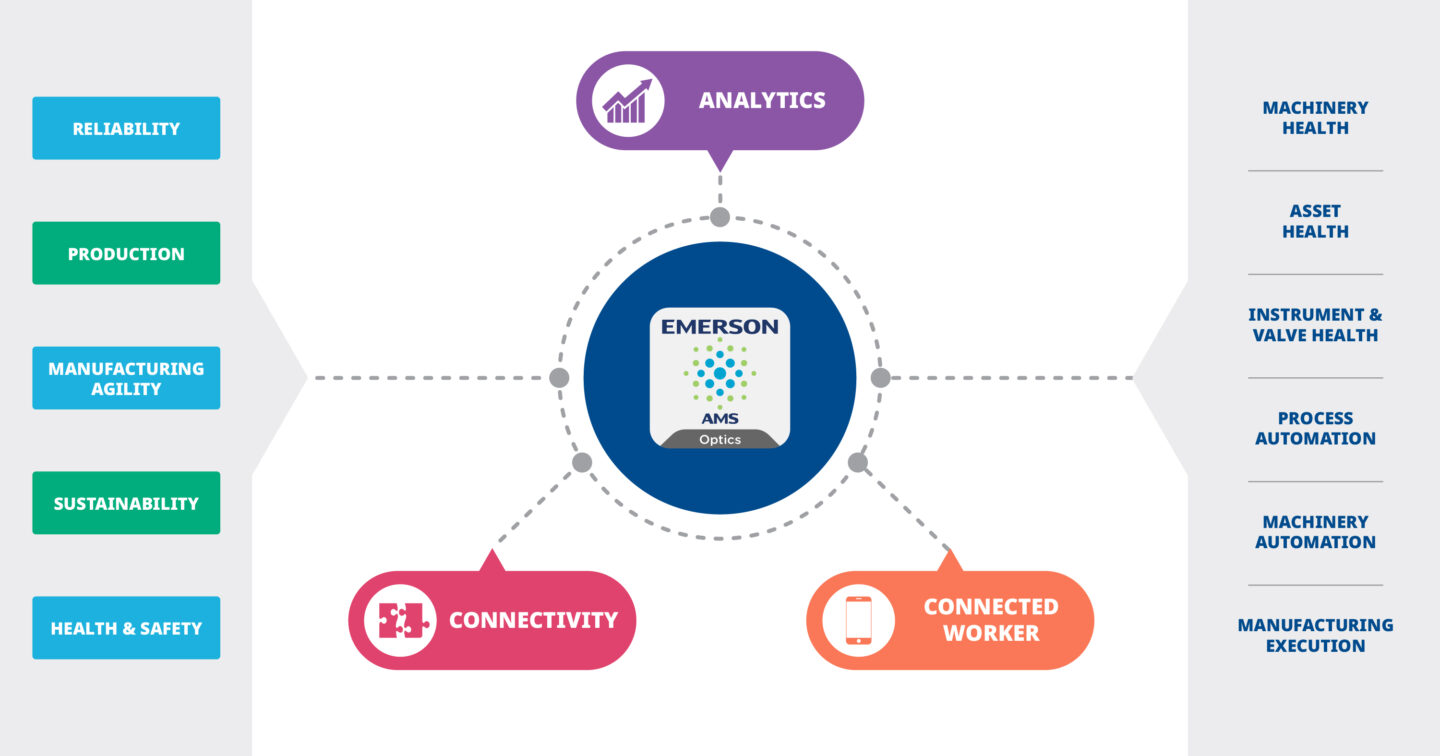

AMS Optics collects, collates, and standardizes data from a wide variety of sources to drive optimized workflows and process improvement across the enterprise.

Few teams have the deep bench of personnel necessary to reconfigure all those assets to ensure consistency and continuity across a plant, let alone an enterprise. But asset management software like Emerson’s AMS Optics can help. An enterprise-level solution can manage assets from the top down, regardless of their underlying configuration. Teams can use the asset management software to build a more structured, cohesive data model that empowers them to quickly and easily isolate problems.

And even more importantly, an enterprise asset management solution turns the raw data it collects from assets into actionable information, and automatically translate that actionable information into the actions that will bring faster results. Erik explains,

“Not only can teams more quickly sort data—by machine, by location, by type, and more—but they can often connect the asset management software directly to a maintenance management system, enabling maintenance teams to immediately start a resolution workflow.”

“In such a configuration, the reliability personnel can immediately create and assign work orders from the same interface (a desktop, or even a mobile device) for any facility in the fleet (Figure 3). They can also track and trend response times and recurrence to identify service bottlenecks and problem assets more easily.”

Erik offers many more suggestions for using enterprise-level asset management tools to increase awareness and improve performance in his full article. He shares how open source information in tools like AMS Optics help create a common data model to drive visibility and action. Head over to Processing magazine to read the article in full.