I heard from Emerson’s Nick Taylor about a webinar on cooling tower condition monitoring taking place tomorrow, August 16 at 9am GMT and repeated at 13:30GMT / 9:30 EDT.

Here’s a brief description:

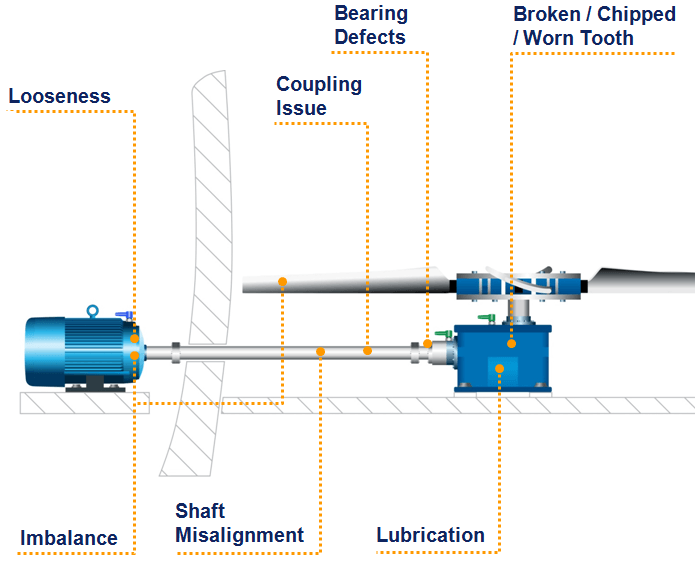

Emerson’s Danny Vandeput will lead the webinar session and discuss ways to wirelessly monitor mechanical draft cooling towers. He will open with their principle of operation, will share ways that they fail, and will highlight the difficulty and cost to repair. Wireless vibration monitoring can provide early warning of many of the mechanical components. There include motor imbalance and coupling looseness, shaft misalignment, bearing defects, gearbox lubrication, and gear wear.Detecting changes in equipment condition like gearbox electrical motors and cooling water conditions are the keys to avoiding cooling tower damage, environmental incidents and negative business impact.

He describes how these components can be instrumented, connected to the IEC 62591 WirelessHART network, and connected into the plant automation system. Beyond vibration, other process variables which can be monitored to diagnose performance include pressure, temperature, and pH / Oxidation Reduction Potential (ORP) for chlorine measurement.

Danny reviews a case study of a motor of a cooling tower and shares the steps and time frame it takes to instrument.

If you have cooling towers in your facility, you may want to register and join in on this webinar.