In a recent Automation World column, The Future is Attainable with Today’s Automation, Emerson Process Management’s former president, John Berra, noted:

The number one issue in process plants is the disruptive cost of an unplanned shutdown. And the number one cause of unplanned shutdowns is rotating equipment. Amazingly, most compressors and pumps are not monitored. Today, there are great sensors for monitoring machinery health, either wired or wireless. The sensors feed a machinery health application that predicts failures before they happen.

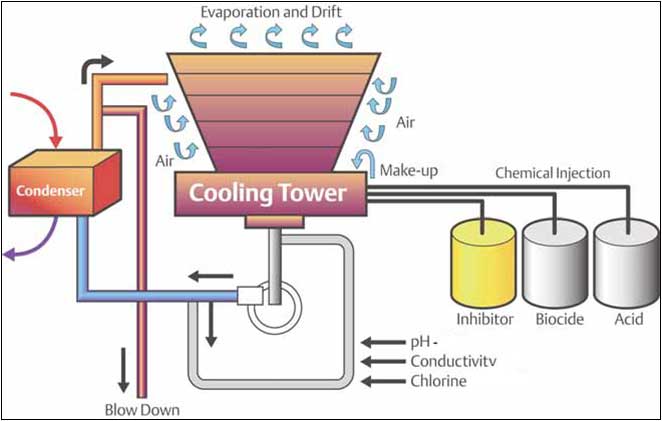

One area where these unplanned shutdowns occur is around cooling towers. Our European team will conduct a webinar next Thursday, December 13 at 14:30 Central European Time / 8:30am North American Eastern Standard time, Condition Monitoring on Cooling Towers with WirelessHart. Here’s the webinar abstract:

Detecting changes in equipment condition like gearbox electrical motors and cooling water conditions are the keys to avoiding cooling tower damage, environmental incidents and negative business impact.

I got my hands on an advanced copy of the presentation and thought I’d share a few points from it. Questions are encouraged to discuss specific issues you’ve faced in your plant.

Emerson’s Danny Vandeput and Bruno Cotteron-Guillonprovide background on mechanical draft cooling towers and their operation.

When they fail, this condition can involve significant downtime and expense to repair and bring the cooling tower back online. These failures can be avoided by measuring vibration at multiple points in this unit.

Beginning with the motor, which drives the cooling fans, wireless vibration monitoring can check for imbalance and shaft looseness. The shaft going to the fan gearbox can be monitored for misalignment and coupling issues.

On the gearbox, wireless vibration monitoring can help identify broken, chipped, or worn gear teeth as well as bearing defects. Gearbox lubrication can also be monitored. This diagnostic information connects to any control systems via MODBUS or OPC and to AMS Machinery Manager software.

If you have cooling towers in your plant, come and register for the webinar armed with your toughest questions.

Update: A kind reader shared that my link to the webinar registration page was broken. I’ve fixed it now.