At last week’s API Storage Tank Conference in San Francisco, California USA, Emerson’s Lance Berry, President & General Manager of the Rosemount Tank Gauging North American team, presented on API-2350 Overfill Prevention Systems.

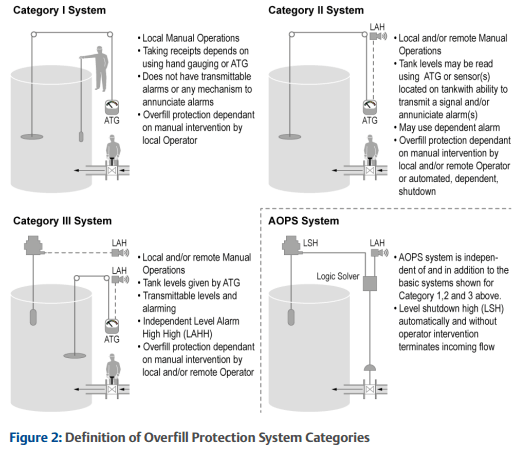

He opened highlighting the three categories of tanks as defined by API 2350 used as a way to classify tank overfill systems. Category 1 is primarily manually operated tanks without transmitted alarms used only in fully attended facilities.

Category 2 requires automatic tank gauging systems for monitoring the tank level and transmitting alarms to a remote location, such as a control room. Category 3, by far the most common tank classification in storage facilities, requires a separate high-high level alarm.

One more category, an Automated Overspill Prevention System (AOPS) is independent of the other categories and is in addition to the three categories. Upon a high-level shutdown condition, it automatically initiates a shutdown of incoming flow to the tank without any manual intervention.

This picture from the excellent resource, The Complete Guide to API 2350, captures the definitions from each of the categories very well:

Lance highlighted Annex C from the API 2350 standard, which describes the types of sensors available for overspill protection including point-level sensors, continuous-level sensors, and automatic tank gauge (ATG).

Point-level sensors can be used for a High-High tank level alarm for Category 1 and 2 tanks. Independent point-level sensors can be used as a High-High Tank Level Alarm for Category 3 and AOPS tanks. Also, there are point-level sensors that may offer self-diagnostic and system analysis for proof testing options.

Continuous-level sensors continuously measure the level of the product in the tank. They can be used to measure both level and provide a High-High Tank Level Alarm in Category 2 and 3 tanks. Also, they can be used as an independent High-High level alarm for Category 3 and AOPS tanks. Some of these sensors offer self-diagnostic and system analysis for proof testing.

Automatic tank gauges are high accuracy continuous-level sensors that meet the specifications for API Chapter 3.1B recommendations. ATGs are suitable for use in Category 1, 2, 3 and AOPS tanks. These automatically calculate the tank Ullage and Innage for the operator to determine the tank capacity for a receipt. ATGs can be used as Independent High-High Tank level alarms in conjunction with another ATG in Category 3 and AOPS tanks and some brands offer self-diagnostic and system testing options that can be used for proof testing.

Lance shared some recommended locations on the tank where these level sensors can be installed. For fixed-roof tanks, manways and nozzles are recommended locations. For floating-roof tanks, proper slotted/holes still-pipe and a floating roof nozzle near the shell are recommended.

Lance closed sharing 10 examples of API 2350 category 2, 3 and AOPS examples with different combinations of point-level, continuous level, and ATG devices. This animated GIF shows the many possible solutions.

Visit the Rosemount Tank Gauging API 2350 site for more on how you can meet these overfill protection requirements.