Emerson’s Hampus Regnér and Christoffer Widahl presented Increase Safety and Efficiency With New Proof Test Method at the Denver Emerson Exchange conference. Here is their presentation abstract:

A functional proof test of a high level alarm (HLA) is required as a key objective of operational safety. Testing and qualification of the HLA device is a critical aspect, which has previously not been well addressed. In this workshop we show how Emerson together with a customer developed a function to address this issue. We will also share case stories on how customers are using this function today to increase safety and efficiency.

Christoffer opened asking if it would be possible to perform high-level alarm testing in 15 minutes. He gave a resounding yes.

Hampus discussed the current methods for testing high-level alarms in tanks. These included:

- Raise fluid level in vessel to high level alarm limit

- Move inventory in and out of test tank

- Float with a pull chain test

- Safety device removed and tested in maintenance shop

The time required is up to half a day and requires continuous monitoring by operators.

Another method for vessels with external chambers is to block the chamber and drain and then flood the chamber. The time can take up to 2-3 hours and requires technicians in the field to perform the procedure.

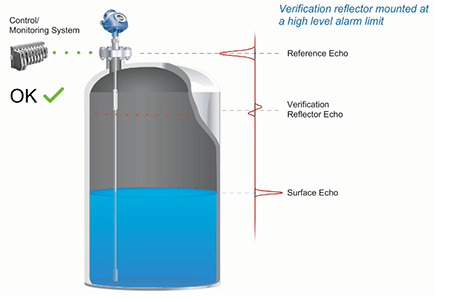

With the Rosemount 5300 guided wave radar (GWR) level measurement device, it does not require removal of the device or raising the tank level. Functional testing of the device is done through a verification reflector. The reflector is mounted at the high-alarm limit, generate an echo and monitor both the reflector and product surface echo.

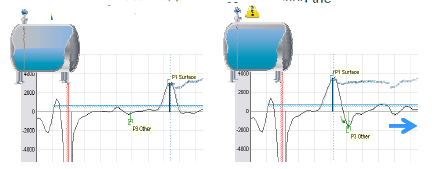

Hi level alarm occurs when the product level rises to or above the reflector. The GWR device is proved by verifying the device is tracking the reflector echo:

In the verification test mode, the TestOutput level corresponds to the reflector position. It verifies that the device is tracking the reflector echo and that the device is capable of detecting a high-level condition without raising the product level in the vessel. Through this test mode, remote testing of the device could also be performed.

With the GWR in test mode, control room operators use AMS Device Manager or technicians can use a 475 Handheld Communicator device. The verify high level alarm is triggered from the control room with a total test time of around 15 minutes—saving 4 hours over prior methods.