Many of the “things” in the Industrial Internet of Things are the sensors that measure not only operating, but also safety-, reliability- and efficiency-related parameters from a manufacturing and production facility.

In a Process Industry Informer article, Enhanced Diagnostics Help To Ensure Reliable Level Monitoring, Emerson’s Marianne Williams shares how technology advancements in vibrating fork level switches help improve operational performance.Marianne highlights the importance of sensors in optimizing reliability practices:

…such as increased condition monitoring and analysis-based predictive maintenance activities – drive down operating costs and improve product or batch quality, health and safety, and environmental compliance.

Advanced diagnostics in these instruments are important, because if:

…potential problems can be diagnosed early, before a failure occurs, then problems can be avoided and maintenance can be scheduled during a planned period of downtime, reducing costs.

Level measurement is often a critical measurement for control and safety shutdown applications such as high- and low-level alarming, overfill prevention, and loss of fluid flow to downstream pump. Vibrating fork level switches can be effectively used in these applications. This technology often replaces traditional mechanical and float technologies:

…because they require minimal maintenance and are very reliable as well as being compact, light in weight and easy to install. Despite being immersed in a tank or pipe and coming into contact with the liquid within, the shape of the fork ensures that a sticky or viscous liquid doesn’t attach itself to the device and drains away quickly. In addition, vibrating forks have an advantage over other level switch technologies in that they do not have moving parts that can freeze or get stuck, which increases their reliability and makes them virtually maintenance-free.

Advanced diagnostics are still very important in spotting performance issues:

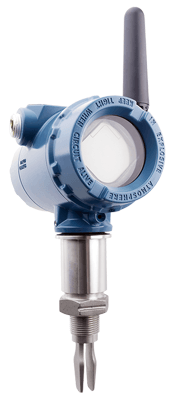

The Rosemount 2160 Wireless Level Detector and Rosemount 2140 wired HART vibrating fork level detector use:…such as electrical failure, build-up of material between the forks, corrosion and possible damage to the forks or sensor.

…HART communications to enable enhanced instrument health monitoring diagnostics that can detect external damage to the forks, internal damage to the sensor, corrosion and over- temperature. A unique frequency analysis function enables any media build-up, fork blockage or excessive corrosion to be detected immediately by a change in the fork sensor frequency over time. This provides operators with an indication that maintenance of the device may soon be needed and gives them the opportunity to schedule it during a period of plant downtime, to minimise process interruption and save money.

When used in safety instrumented system applications, the:

…remote proof-testing capability now eliminates the need for workers to climb on top of the vessel to extract the switch from the process. This greatly reduces the time required to perform the procedure, increasing process availability, worker safety and efficiency.

Read the article for more on these capabilities and applications. The article concludes:

Vibrating fork level switches provide plant managers with an effective means of detecting whether liquid is present or not in their tanks and pipes. More companies are turning to automated level measurement solutions, and devices are now capable of delivering more status and diagnostics information than ever before. Latest generation devices – both wired and wireless – provide advanced diagnostics that can flag up potential problems. This enables managers to resolve them during periods of planned downtime, before they can cause equipment damage or a safety incident and have a negative impact on the plant’s productivity.

You can connect and interact with other level measurement experts in the Level group in the Emerson Exchange 365 community.