What should you expect from a modern control system that you do not get from the older system now running your process? A major improvement in modern control systems is the ability to monitor the performance of the control loop. This includes how well the loop is managing to remain within an expected range of the set point.

HART instrumentation and positioners on the control valve along with asset management software can monitor field device performance and provide diagnostic information. Together this leads to early detection and notification of poor performing control loops causing process variability.

Properly planned control strategies should drive process equipment and unit operations to perform at optimum conditions. Knowledge that the process equipment and unit operations are performing as expected is not readily available using just the process measurements used to provide process control.

Instead, additional process information such as temperatures and flows on energy and utility streams are necessary to monitor process equipment performance. Think of the value of on-line real-time material and heat balance information for monitoring and troubleshooting unit operation performance.

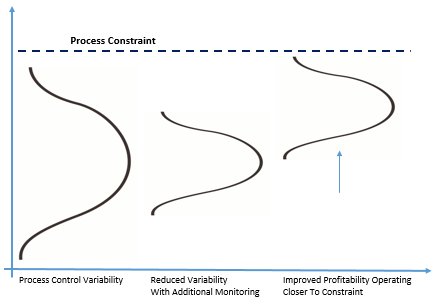

Operators are attempting to run the process operations with as little variance as possible. At times that may mean that they run with a safety factor from a process constraint. However many times, running too far from a constraint causes the raw material yield to be lowered and/or more than optimal energy used in the process unit.

Operators are attempting to run the process operations with as little variance as possible. At times that may mean that they run with a safety factor from a process constraint. However many times, running too far from a constraint causes the raw material yield to be lowered and/or more than optimal energy used in the process unit.

Without measuring the consequences of certain operating set points, this loss of profitability is not seen until monthly performance measures are done and deviations from expected results are noticed. Think of the value of early detection of loss of profitability.

Operations personnel can make quick adjustments to operational set points to move profitable conditions. To do this, the measurements needed to do real-time profitability measurements must be installed. Since many times these measurements are not necessary for process control, they are a good application for wireless instrumentation which can be installed at significantly lower cost than traditional instrumentation.

From Jim: You can connect and interact with other control system modernization experts in the Improve & Modernize group in the Emerson Exchange 365 community.