In this 6-minute YouTube video, PeakVue Signal Processing Demo, Emerson’s Robert Skeirik describes how these advanced analytics can spot bearing problems much earlier that traditional vibration measurements.

This extra time allows the operations and maintenance teams to plan and resolve the issue before a failure occurs.

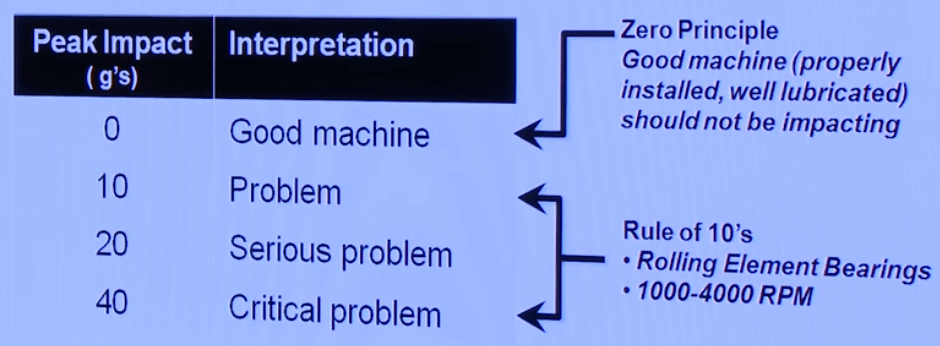

In the video, Robert compares and contrasts simple vibration data measured in inches or centimeters/second versus PeakVue analytics measuring peak impact in g’s (g-force). He shows data of a bearing heading for failure.

https://www.youtube.com/watch?v=_qbz3j04Xdw

The vibration data shows little change as the bearing fault advances in severity until the point of failure. The PeakVue analytics show a steady progression for good, to alert maintenance, to approaching end of life, to failure imminent, to failure. For most equipment, this progression occurs over time to allow maintenance to be scheduled to avoid unplanned downtime.

The PeakVue analytics can also be used for gearbox analysis, as well as two leading root causes of failure—insufficient lubrication and cavitation on process pumps.

You can connect and engage with vibration and reliability experts at the October 1-5 Emerson Exchange conference and/or in the Reliability & Maintenance group in the Emerson Exchange 365 community.