Emerson’s Alex Flick presented Optimizing Power Generation Maintenance Strategies Using Reliability Centered Maintenance (RCM) Analysis at the 2018 Ovation Users’ Group Conference.

Emerson’s Alex Flick presented Optimizing Power Generation Maintenance Strategies Using Reliability Centered Maintenance (RCM) Analysis at the 2018 Ovation Users’ Group Conference.

Alex opened by sharing a story of a North American generating station. The plant was commissioned in 2002 and producers over 500MW of power. The plant has a couple of gas turbines, a steam turbine and heat recovery steam generators (HRSGs).

The plant reliability work practice was time-based, non-quantifiable preventive maintenance that was highly reactive. The maintenance process was loosely defined and had no failure history for root cause analysis.

The capacity factor continued to grow over time and the staff was quite lean. They needed a way to have a supportable and defensible maintenance strategy and improve their equivalent forced outage rate (EFOR).

The approach they took was to look outside for help. Alex explained that this was the point the he and the Operational Certainty consulting team at Emerson got involved. The principals for this project was to use existing knowledge in the combined cycle balance of plant (BOP), get the employees across the plant involved in the project and ongoing program, and validate & expand the analysis and identify the controls.

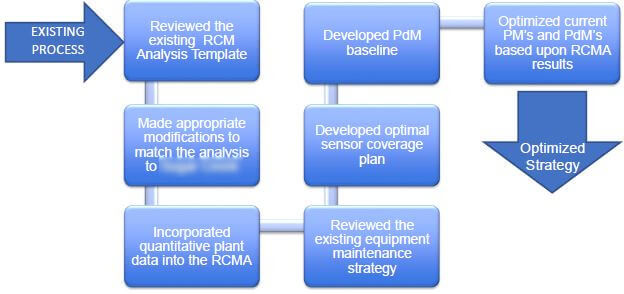

The commitment to the strategy was led from the top by the plant manager and senior staff. The project team followed this approach:

The output of this process is a verifiable, defensible maintenance strategy. This strategy could be quantified to justify plant reliability improvements.

Using an asset tracking and management database, assets are tracked that has an effect on the process should they fail, along with cause of failure, how the conditions leading to failure could be detected, and more.

Preventive maintenance optimization should reduce the overall workload on the organization while directing the available hours to value added tasks. The emphasis is on removing incorrect, irrelevant and obsolete tasks being performed.

There are several levels of maintenance that can be performed including predictive analytics, condition monitoring, predictive maintenance (online and route-based), preventive maintenance and runt to failure (RTF).

Some of the results seen was that the revised processes represented a 50% savings from prior practices. Alex and the team validated the current and future state of predictive maintenance (PdM). Sensor profiles were updated to better monitor failure modes and training was identified for the operations staff.

In the process itself, they identified the need to redesign the HP feedwater valves and the high temperature shut offs for the reverse osmosis (RO) pumps. The existing PMs were optimized and reduced by 40% and rewritten to better reflect the optimized work processes.

The team also documented the need for reliability, equipment, inventory and preventive maintenance strategies. Due to the success of the initiative, the Maintenance Supervisor who was the project’s sponsor is now the Plant Manager for the facility.