Storage tanks containing hazardous materials require safety instrumented systems (SIS) to prevent overfills. Digital technology in the latest level measurement devices used in SIS enables them to be proof-tested remotely, which provides significant advantages.

The consequences of a safety incident such as an overfill can be catastrophic at industrial facilities where tanks contain hazardous, flammable or explosive materials. To minimize risks, tanks must have a robust safety instrumented system (SIS), designed and implemented in compliance with the standards IEC 61511 and API 2350. SIS for overfill prevention include the level sensors, logic solvers and final control elements for each of the safety instrumented functions (SIF) – also known as safety loops – that they perform, and each SIF within the SIS must be regularly proof-tested.

In a Chemical Engineering article, ‘Proof-testing level-measurement devices in storage-tank safety systems’, Emerson’s global functional safety manager AnnCharlott Enberg explains how the latest advanced devices suitable for SIS applications can be proof-tested faster and more easily, and describes the significant advantages this provides.

Proof-tests are operational procedures whose purpose is to uncover dangerous undetected failures (DUs). These are failures that prevent the device from performing its primary function and remain undetected by the device during normal operation. AnnCharlott notes that:

…DUs are measured as failures in time (FITs) and the DU rate is the number of DUs per 109 hours. Ideally, the DU rate should be as low as possible, and selecting an instrument that provides a high level of diagnostic coverage will minimize DUs, and therefore make the device less likely to fail in a dangerous way.

With DU rates being so important, reducing DUs has been a specific aim in the design of the latest level measurement technology. Advanced diagnostics capability enables the electronic and mechanical health of these devices to be monitored continuously, with the result that the number of DUs is significantly reduced.

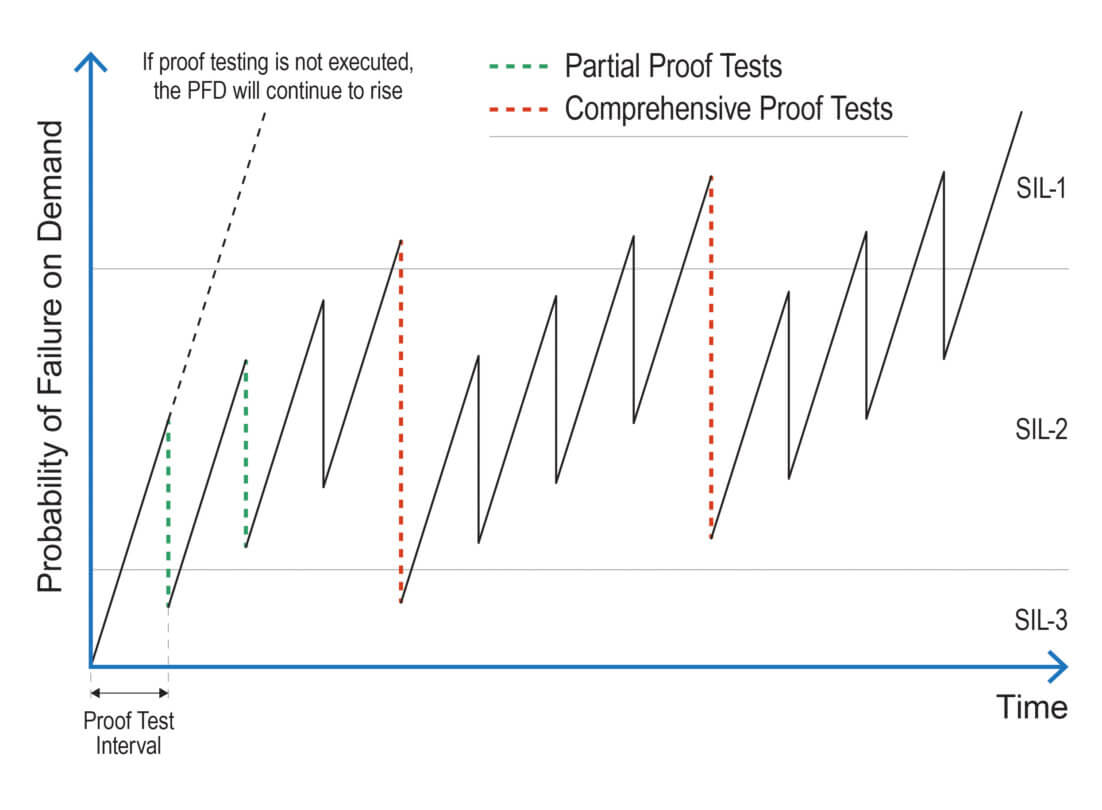

AnnCharlott explains that two types of proof-test – comprehensive and partial – may be performed in compliance with IEC 61511 and API 2350. A partial proof-test has reduced diagnostic coverage compared with a comprehensive test. It may include one or several parts of the safety loop and will bring the probability of failure on demand (PFD) of a device back to a percentage of the original level and ensure that it fulfils its specified safety integrity level requirement.

Caption: A safety loop’s probability of failure on demand (PFD) increases over time after commissioning. Performing a proof-test resets the PFD to a lower value and ensures that the safety loop provides the risk reduction it was designed to do.

However, it is important to acknowledge that:

… partial proof-tests complement – but do not replace – comprehensive tests. Because a partial proof-test detects only a percentage of potential failures, a comprehensive proof-test must eventually be carried out after a given time interval to return the instrument to its original PFD.

Even so, performing a partial proof-test can still provide significant benefits for organizations:

…Partial proof-tests are quicker to complete, require less interference with operations, and crucially, they justify an extension of the time interval required between comprehensive tests, while still remaining within regulatory requirements. This then provides organizations with the freedom to schedule comprehensive tests around planned plant shutdowns, leading to improved plant efficiency.

Proof-testing has traditionally been conducted on location. But, as AnnCharlott explains:

…the digital technology available in modern level-measurement devices enables operators to perform partial proof-testing remotely instead, with the device remaining installed and overfill conditions being simulated to activate the detector and generate an alarm signal. This simulation eliminates the need for fluid to be moved into and out of the tank to perform the test. Simulations avoid the risk of spills, save a significant amount of time and eliminate the need for workers to climb tanks and be exposed to tank contents, thereby increasing worker safety and efficiency.

Caption: Traditional proof-testing methods on large tanks require operators to enter hazardous locations or work at height to access devices, which poses a potential risk to their safety.

The article goes on to describe how the latest vibrating fork switches and radar devices can be remotely proof-tested. With the switches, testing is performed:

…by issuing a HART command. Upon receiving the command, such a device would enter test mode, which cycles the output through wet, dry and fault states, then returns to normal operation. If the proof-test detects an issue, this is reported upon its completion. Using this functionality, the proof-test can take less than one minute to complete, because the instrument remains installed and does not need to be immersed.

The latest non-contacting radar level gauges can be proof-tested safely and remotely from the comfort of a control room:

…using powerful and easy-to-use inventory management software. Built-in functionality guides an operator through inputting a straightforward sequence of settings and commands from their interface, enabling a device to be proof-tested in under five minutes. This achieves considerable benefits in terms of reducing risk and errors, saving time, and increasing worker safety and efficiency.

Caption: The digital technology available in modern level measurement devices enables operators to perform partial proof-testing remotely from the comfort of the control room.

Visit www.Emerson.com/proof-testing to learn more about how Emerson’s proven proof-testing solutions for level measurement devices in SIS can support safer operations. You can also connect and interact with proof-testing experts in the Measurement Instrumentation group in the Emerson Exchange 365 community.