Maintenance programs come in many varieties—reactive maintenance, preventive maintenance, predictive maintenance, and reliability centered maintenance to name some major ones. But what about prescriptive maintenance (RxM)?

In a Process Worldwide article, Prescriptive Maintenance: A Cure for Downtime, Emerson’s Jonas Berge describes the new term as, “…a mashup of prescriptive analytics and predictive maintenance.”

In a Process Worldwide article, Prescriptive Maintenance: A Cure for Downtime, Emerson’s Jonas Berge describes the new term as, “…a mashup of prescriptive analytics and predictive maintenance.”

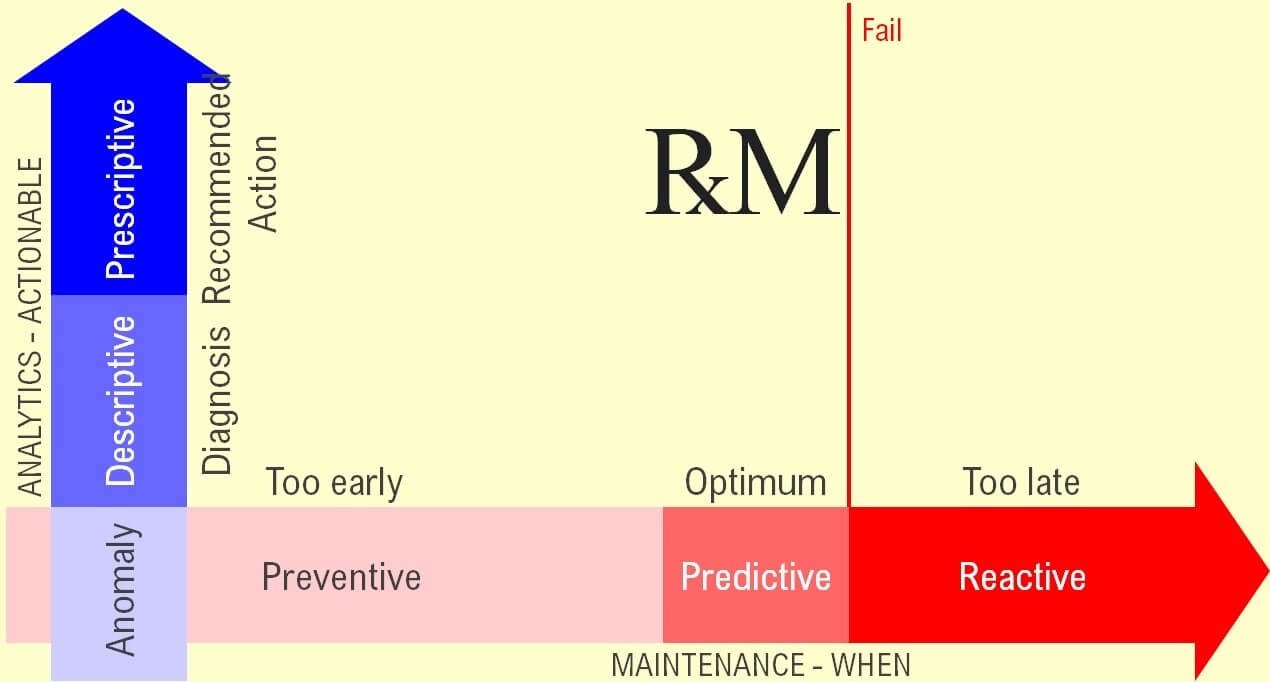

He notes that some illustrations for prescriptive diagnostics in relation to the other forms of maintenance are confusing because:

…they mix the level of ‘analytics detail’ (anomaly detection, descriptive or prescriptive) with the ‘time of maintenance’ (too early, too late, or just in time) on a single axis.

Instead, there should be two dimensions:

- time when maintenance is performed

- the level of actionable analytics

On the time dimension, it:

…is performed as we have traditionally ordered maintenance schemes: reactive, corrective, preventive, predictive, condition-based and proactive.

The actionable analytics dimension includes:

…anomaly detection, descriptive and prescriptive.

Descriptive and prescription analytics are time tested and often called diagnostics. Anomaly detection:

…means that analytics detects something that is not normal but can’t tell what it is, and therefore there is no associated description or recommended action.

Since plant assets mainly operate in normal conditions and often don’t have sensors for vibration, acoustic noise, bearing temperatures, etc., machine learning (ML) algorithms using only process data:

…can in this case only be trained for what ‘normal’ operations look like, and thus can only tell that anything outside of this normal operating window is ‘abnormal’ or an ‘anomaly’.

Data from the production process:

…is more dynamic, changing all the time with process upsets or smaller variability caused by variations in feedstock, catalyst, weather or other factors. That is, historian data probably contains many samples of process upsets that can be used to train ML to predict a process upset and differentiate between them, such as a change in Reid vapor pressure (RVP).

Read the article for more as Jonas describes descriptive analytics, prescriptive analytics, recommended actions (prescription), and scaling RxM over time to more and more of the plant assets.

You also may want to check out Jonas’ deep library of essays in LinkedIn on various aspects of digital transformation.