The environmental risks associated with carbon emissions have escalated over the last several decades. Although modern technologies like burner and boiler systems have enhanced our standard of living, they’ve also created long-term negative consequences in the form of rising greenhouse gas (GHG) emissions.

The environmental risks associated with carbon emissions have escalated over the last several decades. Although modern technologies like burner and boiler systems have enhanced our standard of living, they’ve also created long-term negative consequences in the form of rising greenhouse gas (GHG) emissions.

One of the ways we can effectively reduce these risks is by modifying the fuels we use within heating applications, swapping out conventional fossil fuels for biofuels.

Biodiesel Versus Renewable Diesel

Two examples of biofuel include the following:

- Biodiesel — a cleaner-burning alternative to diesel fuel. It can be produced from renewable resources, such as vegetable oils, animal fats and recycled cooking grease in a process called transesterification, during which the fat or oil reacts with an alcohol to create fatty acid methyl esters (FAME).

- Renewable diesel — a higher-quality biofuel that can be used in concentrations up to 100 percent. Also known as hydrotreated vegetable oil (HVO), renewable diesel doesn’t involve transesterification. It also doesn’t produce glycerol as a byproduct of the chemical process.

Biodiesel and renewable diesel have lower emissions compared to traditional fossil fuels and can reduce GHG over the entire lifecycle of the burner.

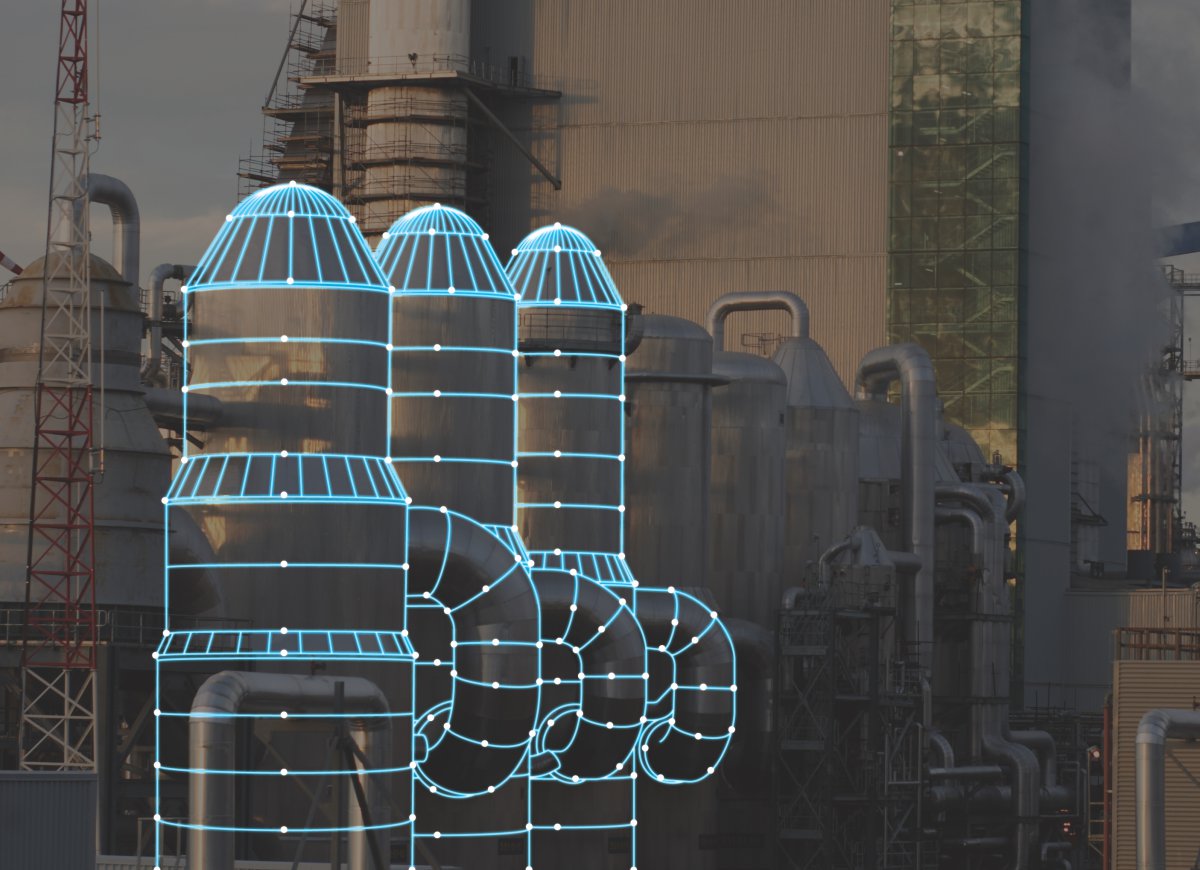

Implementing the Right Components

By upgrading boiler fuel trains to support biodiesel, it’s possible to reduce emissions by as much as 50 percent compared to petroleum, moving you closer to net-zero targets and avoiding costly state penalties for emissions levels. To ensure compliance, it’s important to work with boiler manufacturers that use components — the valves on the fuel and pilot lines, for example — that meet new regulatory standards for 20 volume percent biodiesel (B20). These are blends with 20 percent biodiesel and 80 percent diesel fuel.

Examples of components that meet the B20 standards include ASCO™ Series 262 and 263 Biodiesel Valves, which are the only certified safety shutoff valves on the market for use with biodiesel blended fuel in industrial and commercial burners. Valves like these make it possible to transition to a more sustainable energy source, simplifying compliance with evolving regulations and reducing greenhouse gas emissions. As part of their compliant design, these valves feature elastomers that have undergone testing to ensure their long-term chemical compatibility with corrosive biodiesel.

To learn more, please visit: www.emerson.com/combustion.