When it comes to driving more sustainable operations forward, how do you prioritize your actions? At the 4C Health, Safety & Environmental Conference, Emerson’s Doug White presented How to Evaluate Sustainability Options. Here is the presentation abstract:

To reach greenhouse gas emission reduction targets, many state, regional and national governments have implemented or are considering implementing low-carbon fuel and fuel efficiency standards. The oil refining and chemical industries are large contributors to worldwide greenhouse gas emissions and are subject to these standards. In response, most major refining and chemical companies have announced Scope 1 and 2 Sustainability and Net-Zero targets. Possible investments to meet these regulations include energy efficiency projects; carbon capture, utilization, and storage (CCUS); increased hydrogen fuel use; biofuel feedstocks and products; increased renewable-based process electrification and others. Investment decisions on the selection of investments must be made in an uncertain business environment with substantial feedstock/ product price volatility and limited capital availability. Advanced software and advanced automation applications can help guide overall emission reduction investment decisions and support cost-effective implementation of the recommended strategies. In this presentation we will review these applications and investment decision aids and case studies of their use.

Doug opened by sharing common sustainability goals such as emissions management, hydrogen production increase, carbon capture and storage, and use of renewable energy to replace fossil fuel-based energy.

The challenge is to meet sustainability goals while remaining profitable to remain an ongoing business. A key part of meeting these challenges is using modern industrial software and automation tools to reduce emissions while dramatically improving planning operations and maintenance.

Some mitigation strategies for refinery & petrochemical manufacturing operations are to drive energy efficiency, employ carbon capture, increase hydrogen usage, use bio-based feedstocks, use renewable power, and improve emissions management.

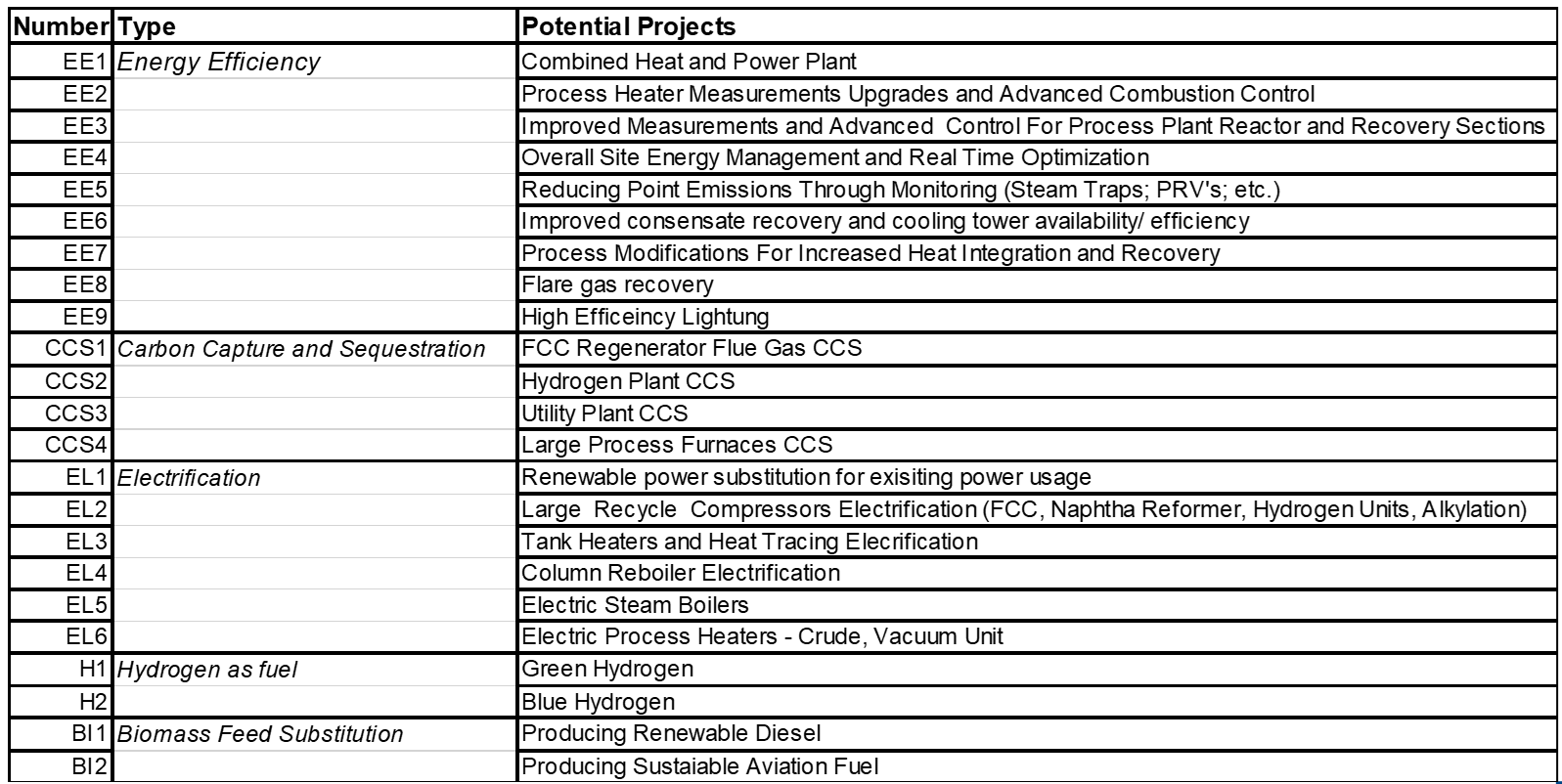

Advanced software, analytics, and embedded diagnostics in instrumentation can identify problems with production assets before they lead to lower efficiency or unplanned downtime. Energy Management Information Systems can monitor real-time energy usage and track actual versus expected. It displays the financial impact of inefficient operations and enables optimization efforts to be justified and enacted sooner. Here are some possible emission reduction project possibilities:

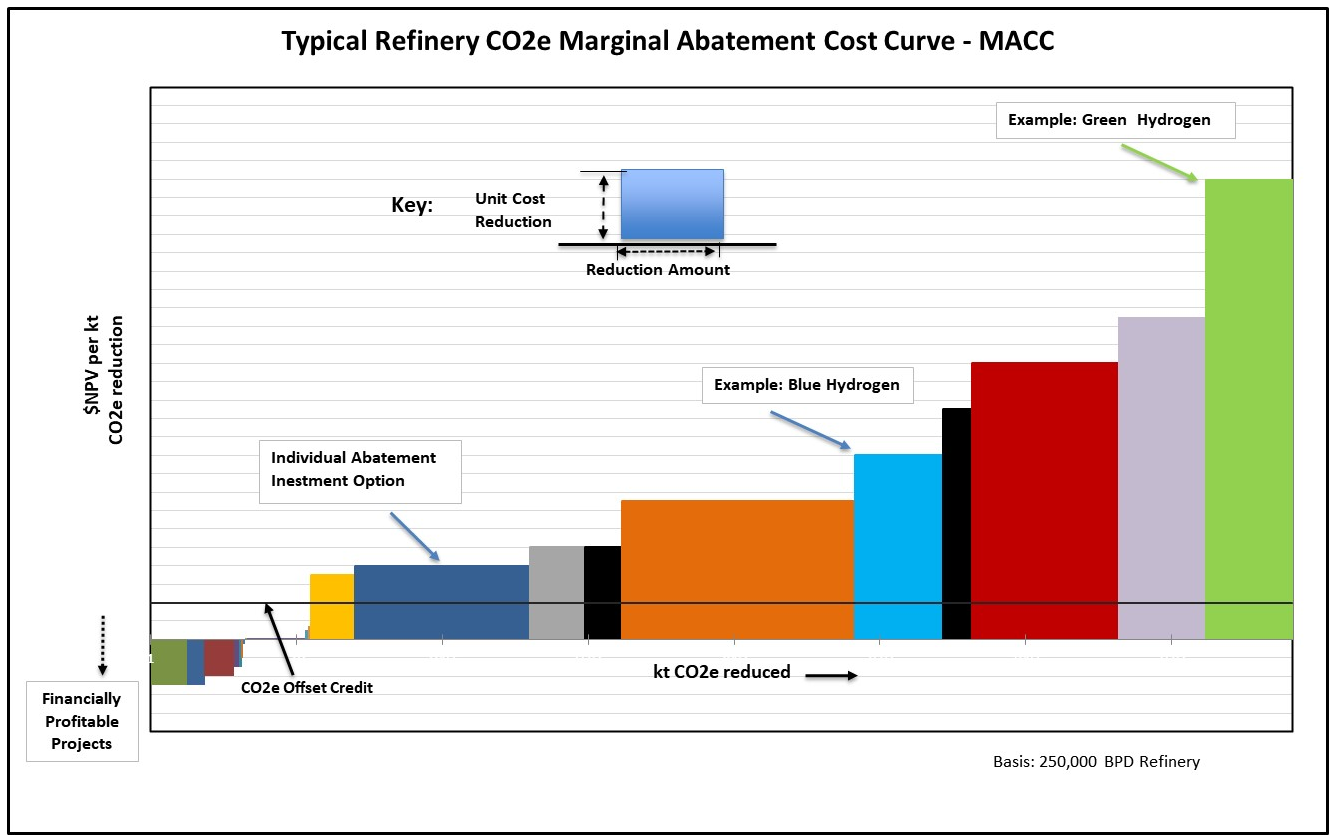

Doug explained a marginal abatement cost curve to identify which investments should be chosen first to maximize sustainability impact yet have positive ROIs. This model examines uncertainty in many dimensions, including the availability of process technology, the efficacy of that technology, reliability in mean-time to failure, and mean time between failure.

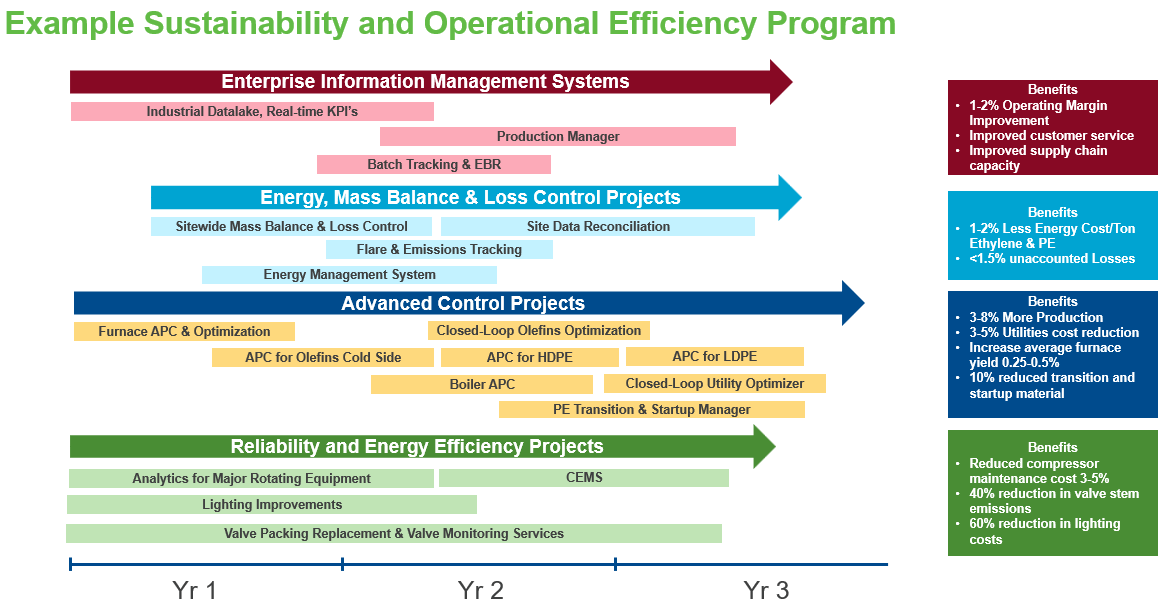

Here is an example program that could be implemented based on this approach.

A sustainability assessment workshop, a structured collaborative process to build consensus on the top priorities and sustainability impact, is essential. The workshop should be structured with expertise from multiple plant and corporate office disciplines. The results from this workshop or series of workshops are an investment options evaluation. This evaluation includes a preferred sequence of projects, expected costs, and expected emission reduction per date.

Doug and the Emerson consultants can help in facilitating these workshops and developing the investment options evaluation.