At the Emerson Exchange Immerse conference, the user community was treated to a presentation on how safety instrumented systems were incorporated into PureCycle Technology‘s “Born Digital” strategy.

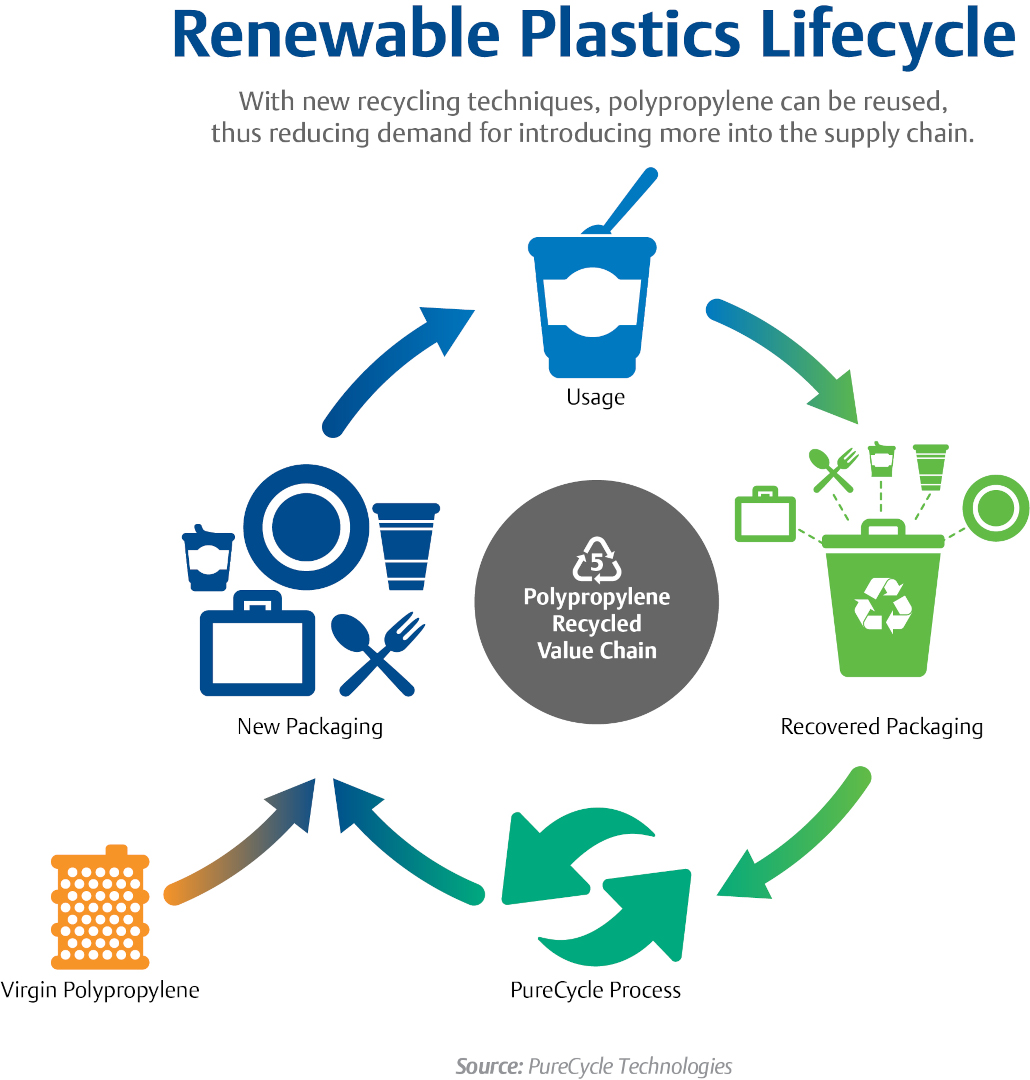

PureCycle Technologies transforms polypropylene (PP) plastic into a versatile, replenishable resource through a unique purification process that separates color, odor, and other contaminants into ultra-pure recycled resin. PureCycle Technologies’ Charles Qi shared an update on their “Born Digital” strategy as it applies to process safety.

PureCycle Technologies transforms polypropylene (PP) plastic into a versatile, replenishable resource through a unique purification process that separates color, odor, and other contaminants into ultra-pure recycled resin. PureCycle Technologies’ Charles Qi shared an update on their “Born Digital” strategy as it applies to process safety.

The process contains flammable chemicals, high pressures, high temperatures, and complex processes and equipment. They needed to comply with OSHA CFR 1910.119 (process safety management of highly hazardous chemicals). The DeltaV SIS safety instrumented system is designed to mitigate the risks that could cause personal impact, environmental damage, and asset loss. The SIS is fully automated to provide greater confidence for operations compared with a manual response.

Their SIS project followed IEC 61511/ISA 84 for its entire lifecycle approach they established a corporate SIS engineering standard. The organization has dedicated SIS experts and engineers and worked with Emerson SIS experts during the greenfield project. The SIS was part of the total digital automation “Born Digital” strategy. The DeltaV platform is used for the basic process control system and safety instrumented system, which enables more efficient execution, responsive support, and reliable upgrades.

The project followed the IEC 61511 and the PureCycle Technologies SIS standard, through the facility design, SIS design, and ongoing operations and maintenance. The process has 70 safety instrumented functions and 20 interlocks. The control system had about 1500 control loops. Smart Commissioning using AMS Device Manager enabled efficient loop checks for 500 loops for the SIS and fire & gas system. It really helped them meet a tight project schedule.

Charles summed up the results. The greenfield plant site started up in May and has been running with only very few spurious fuel gas flow sensor trips and some fire & gas false alarms to date.