Due to stringent greenhouse gas emissions regulations, as well as ongoing technical advances, electric valve actuators are proliferating across process industries, but until recently, these actuators have lacked comprehensive diagnostic and monitoring features.

This situation is changing for the better, as we explain in Hydrocarbon Processing November 2023 article, titled “Maximizing the Advantages of Electric Actuator Diagnostics,” we discuss recent software developments that empower users to monitor these devices and respond proactively to developing issues.

The rise of electric actuators

Historically, electric actuators have seen limited use because they offered relatively little torque, were prone to failure, and lacked sophisticated diagnostics and communication capabilities. Today, in conjunction with the need to curb emissions, improved designs and technological advancements have addressed these and other issues, creating a surge of interest in electric and electro-hydraulic actuators.

Modern zero-emissions electro-hydraulic and electric actuators now include fail-safe springs and advanced diagnostics, and they have very low power requirements

Especially in situations where pressurized air is expensive or unavailable, or where emissions must be reduced to zero, electric actuators are an attractive option for new valve installations and retrofits alike. However, unlike pneumatic actuators, electric actuators have generally lacked options for connecting to asset monitoring networks.

New connectivity solutions

The development of new software applications specifically for electric and electro-hydraulic actuators addresses this need, providing much-needed features, such as access to device status and alarms.

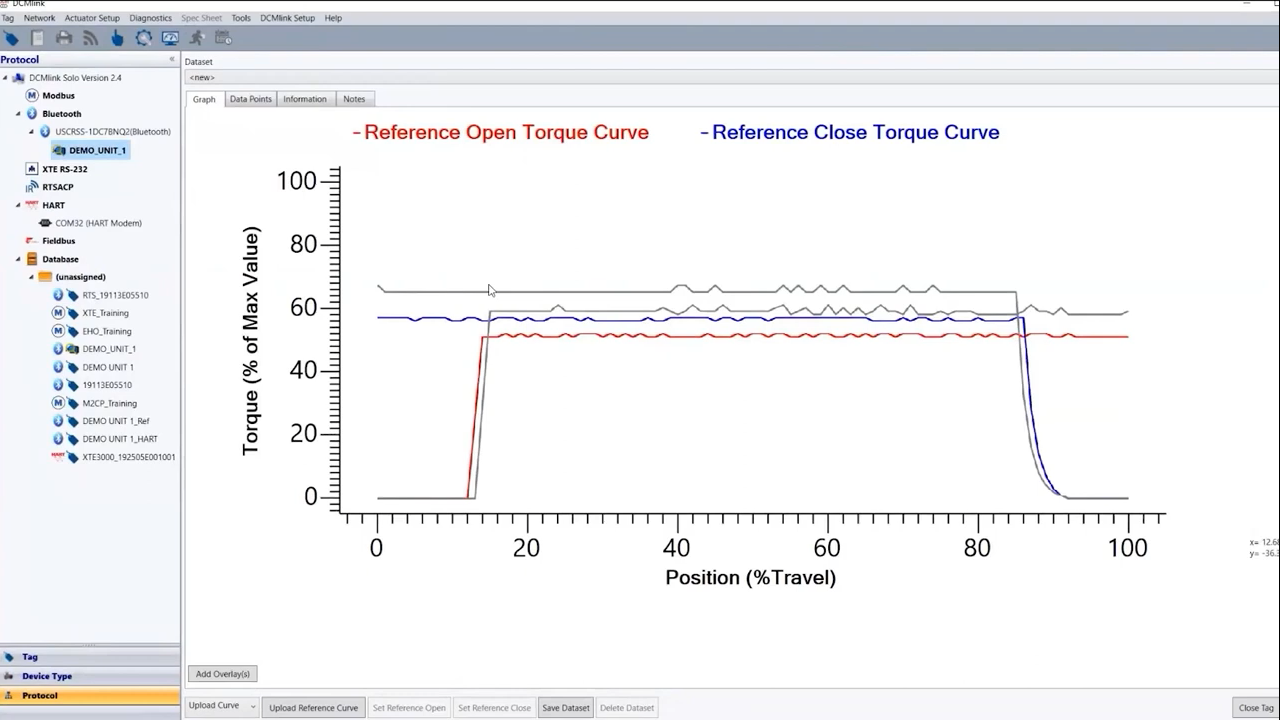

More advanced applications provide extensive features, including the ability to perform local partial stroke tests, upload and download valve configurations (remotely or locally), and capture and store stroke curves for analysis, troubleshooting and side-by-side comparison.

Electric actuator valve software applications provide access to the valve and actuator data, enabling local valve testing, stroking and monitoring.

Advanced analytic applications can use historical performance data and alarm logs provided by smart actuators to identify current and developing problems, and to offer maintenance suggestions. This empowers users to plan outages and avoid unexpected downtime, resulting in more efficient operations.

Evaluating actuator software

With a variety of software options to choose from, users should consider which capabilities are most important for their application. Features to look for include:

- Integration with existing asset management software

- Actuator parameter configuration

- Real-time data monitoring and storage

- Device logs and historical data

- Comparison of torque and performance curves to historical data

- Stroke testing

- Intuitive access to data and alarms

- Diagnostics that identify problems and suggest possible solutions

- Support for a variety of wired and wireless communication protocols

- Local and remote access from laptop, smartphone, or tablet

- Open architecture for integration with devices from multiple vendors

Analytics in action

A chemical plant using electric actuator monitoring software discovered that some valves gradually developed a spike in closing torque due to product buildup. This enabled them to identify and clean these valves before production was affected.

In another application, monitoring software analytics detected a power supply problem, facilitating repair before an outright failure occurred.

A third company regularly uses Bluetooth to connect to their software and perform partial stroke testing, allowing them to extend their safety instrumented system interlock testing intervals, and to identify valves beginning to coat and plug.

Conclusion

Modern electric valve actuators offer far more than their simpler predecessors, and as a result they are seeing widespread adoption throughout the process industries. Advanced monitoring software provides early notice of developing problems as well as actionable suggestions, empowering maintenance teams to intervene and prevent production impacts.

Visit the Valve Actuation and Electric Actuators section on Emerson.com to know more about actuator operation, technology, control, monitoring, and diagnostics.