Turbine bypass valves are subject to frequent thermal cycles, high pressure drops, and the need for tight shut off. My article in the May 2023 issue of Power, titled “Turbine Bypass Valve Challenges,” provides methods of inspection to prevent their failure.

Surviving severe service

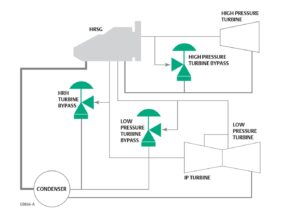

Turbine bypass valves are used to bypass steam turbines during plant startup and shutdown, as well as when a turbine trips off-line.

Depending on the power plant design, several turbine bypass valves may be employed to instantly shunt steam around a turbine should it trip offline

In normal operation the valves are completely closed, forcing all the steam through a turbine. During startup, bypass valves divert steam away from the turbine until the properties and conditions of the steam are appropriate for sending to the turbine. This process happens in reverse at shutdown.

Steam must continue flowing if a turbine trips to prevent equipment damage due to overpressure and high temperature, so the turbine bypass valve immediately opens to maintain flow through the system.

When the turbine bypass valve(s) opens, the exit steam is superheated, posing a danger to downstream equipment. To mitigate this issue, turbine bypass valves either incorporate a water injection system in the valve body or employ a separate water injection desuperheater just downstream.

Inspecting for issues

Most turbine bypass valves will ultimately fail in some way due to the punishing conditions under which they operate.

The extreme pressure drops invariably generate high noise and high vibration. Over time these vibrations, coupled with frequent temperature changes, fatigue the metal in the valve, water connections, and the piping itself.

Over time, the high vibrations and thermal shock experienced by turbine bypass valves will fatigue the metal and create cracks in both the valve itself and the surrounding piping

Every turbine bypass valve and its associated piping should be routinely inspected to detect impending issues, either by plant personnel or the valve vendor.

Welds on the valve body and surrounding piping should be inspected, along with water injection nozzles and the desuperheater.

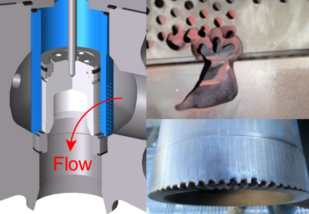

There are also threats to trim components, such as seat surface erosion. One common expression of such erosion, specifically on the plug, is often referred to as “gear toothing.” This occurs more commonly in flow down valves, where the steam accelerates through the cage holes and then strikes the trim/seat area directly, causing excessive wear and reducing service life.

Flow down valve body designs are prone to trim damage as the wet, erosive steam passes through the cage and impacts the seat

Required maintenance ranges from replacement of inexpensive components to installation of a completely new unit.

Avoiding issues with upgrades

Because many turbine bypass valves have been in service for decades, they lack the advantages newer designs provide, such as the latest sealing technology. Another upgrade example is replacing the welded diffuser with a removable two-in-one seat diffuser to reduce required maintenance.

When a new unit is needed, potential improvements should be investigated, such as valve orientation.

Downward flowing valves with horizontal actuators were the main option a few decades ago for turbine bypass valves. New flow up valve designs may be installed without piping modifications in most instances, providing extended service life and improved performance.

For flow down valves, vertical mounting of the actuator results in reduced and more even wear, longer runs between maintenance outages, and improved actuator response.

In the case of horizontal actuator flow down designs with sufficient overhead space, a flow up design can easily meet the existing face-to-face requirements of the old valve, while reducing some of the wear common to flow down designs with a horizontal actuator.

Flow up valves significantly extend seat and trim service life because the steam is moving relatively slowly as it passes over the plug and seat. As the steam moves through the small holes of the cage, it accelerates significantly, but that energy dissipates into the large body cavity of the valve, rather than striking the seating surface.

Seek expert advice

Turbine bypass valves are highly specialized pieces of engineered equipment that must be carefully specified, installed, inspected, and maintained, so users should reach out to trusted experts for assistance.

Many of these vendors offer full inspection and health check services to identify areas where metal fatigue and stress cracking are developing. Ideally the valve can be repaired, but if a valve replacement is warranted, the vendor can also provide guidance in evaluating bypass valve design styles and choosing the best option for the specific application.

Visit the Steam Conditioning and Desuperheating section on Emerson.com for more on how you can improve the thermal efficiency and protect downstream of your plant.

About the Author

Chris Roling is a product engineer in the Steam Conditioning Group at Emerson, and he holds a B.S. degree in Mechanical Engineering from Iowa State University. Roling has been working with steam conditioning products since 2017, and he is responsible for valve design, as well as factory and field issue support, for Emerson’s steam conditioning products.