Leaders worldwide continue to pursue hydrogen as a dependable energy carrier in the global energy mix. But hydrogen, as a light gas, has challenges in the supply chain from production through ultimate use as an energy carrier. Challenges that Emerson has addressed include hydrogen embrittlement, permeation, and leak detection to make the transportation and consumption of hydrogen blended gases a safe and eco-friendly reality.

The U.S. Department of Energy explains that a:

…viable hydrogen infrastructure requires that hydrogen be able to be delivered from where it is produced to the point of end use, such as an industrial facility, power generator, or fueling station. Infrastructure includes the pipelines, liquefaction plants, trucks, storage facilities, compressors, and dispensers involved in the process of delivering fuel.

Pressure-regulating technologies are essential for safe, efficient, and reliable hydrogen distribution. In many cases, hydrogen can be blended with natural gas for transport through existing pipeline infrastructure. For natural gas transmission and distribution companies, blending Renewable Natural Gas (Biomethane) and Hydrogen into their infrastructure accelerates the transition to a carbon-neutral energy supply.

Emerson has an over 60-year history of supplying pressure-regulating technologies for hydrogen applications. To further certify products for hydrogen service, Emerson utilizes their engineering and testing experts at their test and evaluation facility in El Campo, TX to validate product usage in applications up to 100% hydrogen. Pressure regulating compatibility statements are now available in the Decarbonization in Natural Gas Applications section on Emerson.com.

These compatibility statements are available for the North American, European and Asia Pacific regions. A compatibility statement for Anderson Greenwood and Crosby pressure relief valves is also available. More products continue to be added to this list as Emerson’s Test & Evaluation team confirms product compatibility with hydrogen through extensive testing. Hydrogen certifications from Emerson are now offered with each hydrogen-ready product ordered.

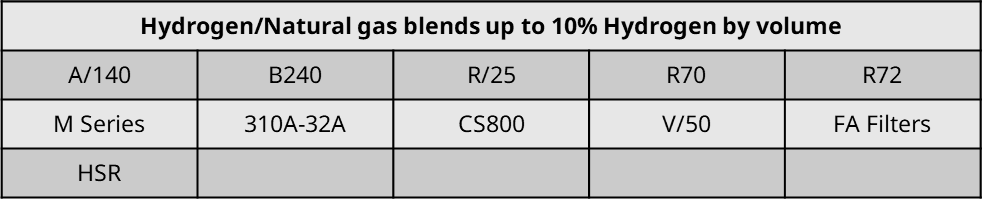

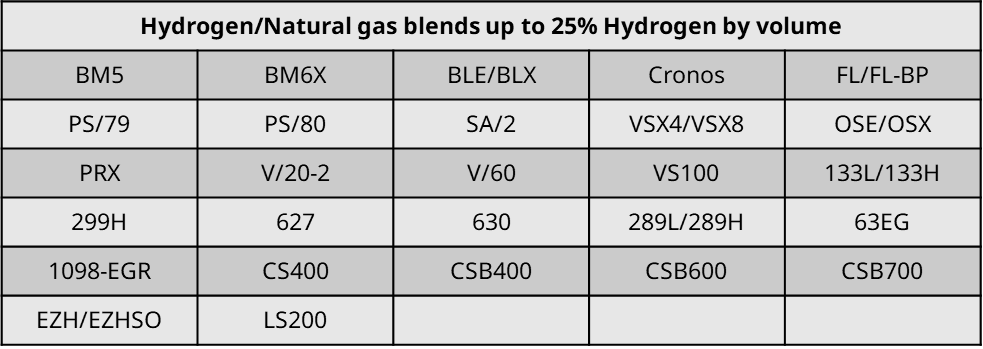

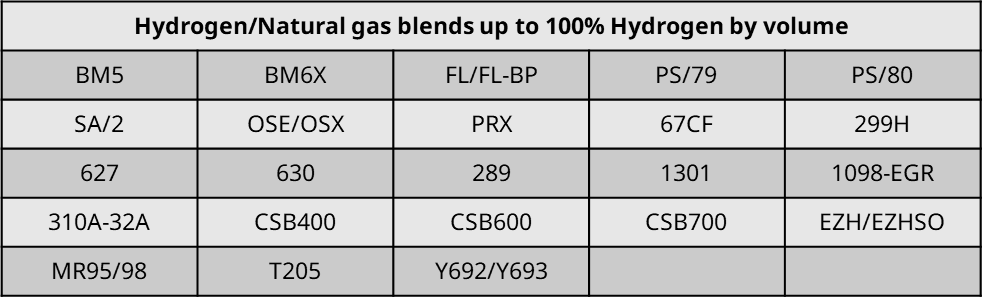

Combined Tables from the North American, European, & Asia Pacific Compatibility Statements

The following product families have gone through a material evaluation and testing process. Specific constructions have been approved for use in 10%, 25%, and 100% Hydrogen by volume. Please contact your Emerson Impact Partner or Sales Partner for more information.

Anderson Greenwood & Crosby Relief Valves

Anderson Greenwood & Crosby pressure relief valves have many types of pressure relief valves suitable for cryogenic to high-temperature hydrogen applications currently up to pressures of 10,000psig / 690barg, with higher pressures possible depending on the application. The exact type and configuration can be selected to match application needs and process conditions best.

The suitable direct spring pressure relief valves for this service include:

- Crosby J-Series, 1”x2” to 12”x16”

- Crosby OMNI, ½”x1” to 2”x2”

- Anderson Greenwood Series 80 ½”x¾” to 2”x3”

The suitable pilot-operated pressure relief valves for this service include:

- Anderson Greenwood Series 200 1”x2” to 10”x14”

- Anderson Greenwood Series 400/800 1”x2” to 10”x14”

- Anderson Greenwood Series 90/9000, 2”x3” to 14”x18”

Follow the links above and visit the Decarbonization in Natural Gas Applications section for more on the expertise and integrated solution support for achieving decarbonization goals while ensuring safe gas supply and maximum system reliability.

Additional Resources:

Hydrogen Blending Applications Brochure

Webinar: Blending H2 with Natural Gas – Technical Factors to Consider

Transporting H2 in Natural Gas Pipelines

Renewable Natural Gas Solutions