In today competitive landscape, manufacturers are facing lots of pressure to improve efficiency, reduce waste, and keep workers safe.

One common solution they rely on, to address these challenges is usually found in Robotics.

For example, in the automotive industry alone, more than one million robots are currently utilized. They play a critical role in the transformation of the factory floor, and one element is particularly important: end-of-arm tooling.

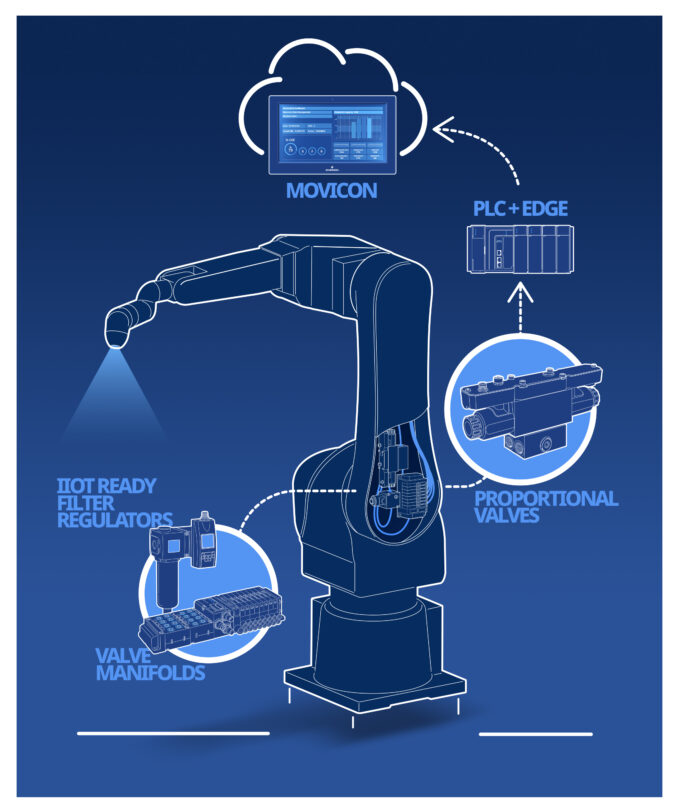

High-performance solutions, including solenoid valves, pressure regulators and proportional valves, can play a role in reducing waste materials such as paint sludge. Components placed at the end of a robotic arm must interact with the product or product elements.

End of arm tooling are placed at the end of a robotic arm and interact with the product or product elements to enable the robot to perform tasks. Common tasks may include welding, painting or gripping.

To make robotics an effective factory automation tool, end of arm tooling must be combined with pneumatic power systems: these solutions use power to generate motion and help operators to reliably, quickly and more efficiently perform a wide number of tasks, like force control, assembling, handling and cutting.

But how pneumatic systems, combined with robotics can help manufactures to transform and improve their production?

Here’s something to consider:

- They can boost efficiency and quality: Precise control of air and gases translates into consistent results, like perfect paint jobs with minimal waste.

- They can reduce waste and energy consumption: Smarter systems minimize overspray and leaks, saving you money and protecting the environment.

- They can enhance operators’ safety: Pneumatic systems can be integrated with various safety systems resulting in safer operations for workers in though environments

- They can gain real-time visibility: With real-time monitoring of compressed air usage operators can make data-driven decisions to optimize performance and identify and correct problems before they lead to downtime.

There’s no doubt pneumatics systems are key components in robotics applications and represent a crucial technology for enterprises who wants to transform the factory floor.

If you want to know more about this topic and find out how to gain a competitive advantage with advanced technologies that combine fluid power and robotics, read this article from Emerson expert Sumit Kapde, (Global Business Development Manager – Robotics and Proportional Valves) appeared on Fluid Power Journal.