Emerson’s Anna Velena, Tinh Phan, and Eric Snyder collaborated to present “Maximize Field Device Management using AMS Device Manager and AMS Trex” at the Emerson Exchange 2025 Conference. Here is their presentation abstract.

Field Device Management (FDM) plays a critical role in optimizing industrial operations by enabling efficient monitoring, configuration, and maintenance of instruments and valves. Explore how FDM enhances operational reliability by ensuring devices are correctly calibrated and functioning, reducing downtime through predictive maintenance. Learn how to streamline data management, offer real-time insights into device performance, and proactive decision-making. Improve compliance with industry standards by maintaining accurate device records and audit trails. Hear how your peers are using AMS Device Manager and AMS Trex to achieve best-in-class FDM by taking advantage of the full functionality available.

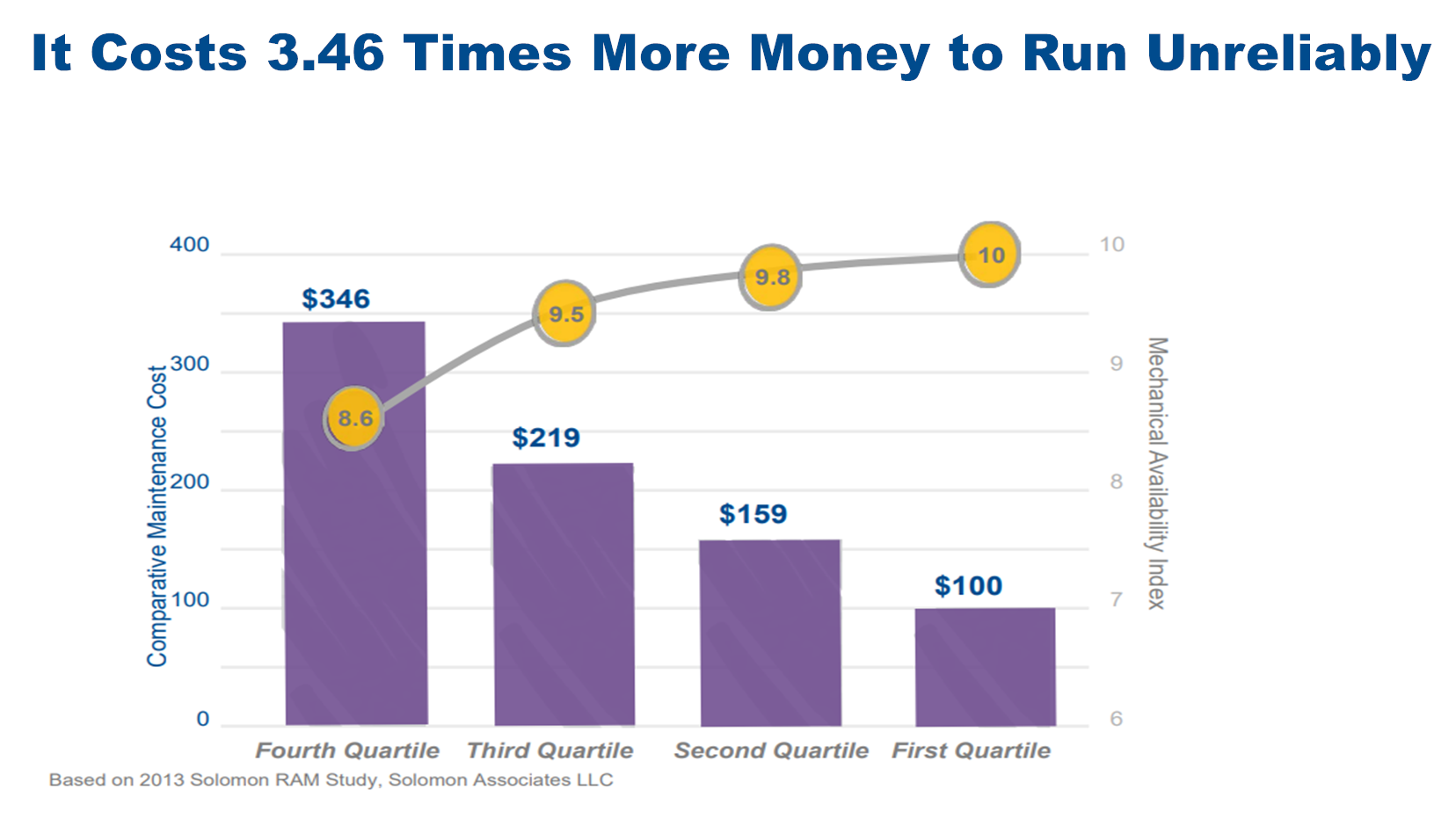

Eric opened by noting that studies point to reliability as the most significant opportunity for improvement in manufacturing and production operations. Assets will inevitably fail. But the earlier you can detect that it is on the path to failure, the less costly the fix will be.

Failures follow predictable patterns, including infant mortality, random break-in, fatigue, wear-out, and the bathtub curve. The level of asset failures varies significantly between the first and fourth quartiles in terms of reliability performance.

AMS Device Manager can manage all registered HART or Foundation Fieldbus devices from any automation supplier. It can manage up to 30,000 devices and connects to 20+ control systems, safety instrumented systems, PLCs, gateway interfaces, modems, and field communicators.

AMS Device Manager is a single system that can seamlessly integrate devices from multiple standalone systems, providing a unified interface, database, user security, and a single environment for comprehensive device management, predictive diagnostics and documentation.

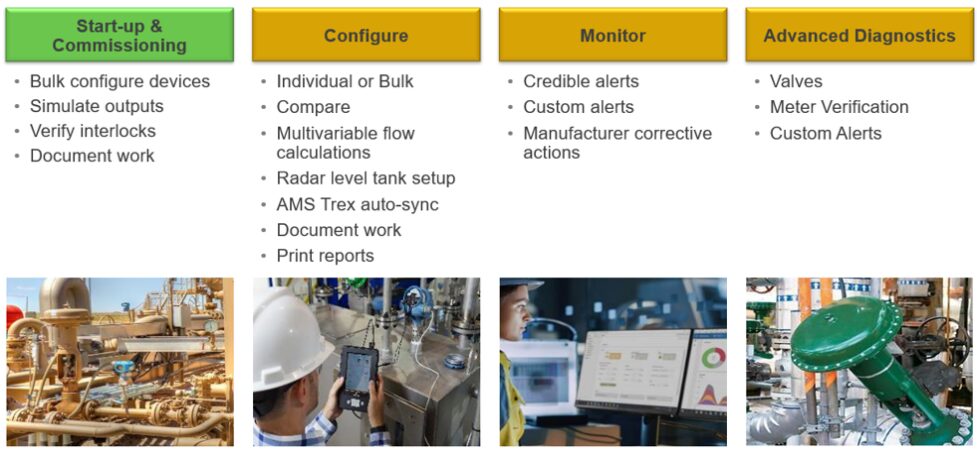

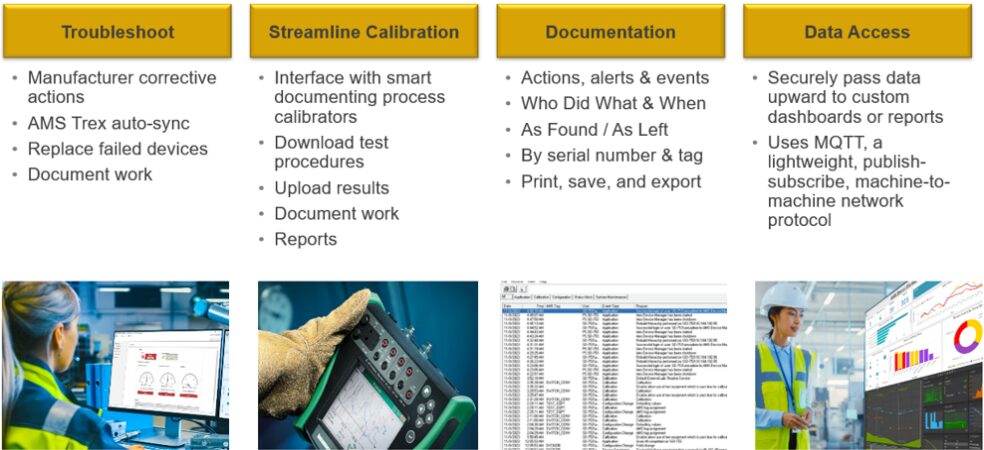

AMS Device Manager helps with start-up, commissioning, configuration, monitoring, and diagnostics. It can also help streamline shutdowns, turnarounds, and outages in the performance verification of the measurement and final control devices.

It performs numerous functions to help drive reliability and productivity improvements. Here are some categories and work functions where it can help.

The AMS Trex Device Communicator can commission, provision, configure, diagnose, and troubleshoot any HART or Foundation Fieldbus devices. It is intrinsically safe, certified to ATEX, CSA, FISCO, and IECEx standards. Apps include Loop Diagnostics, Fieldbus Diagnostics, ValveLink Mobile, WirelessHART Provisioning, and Radar Master.

Changes made by AMS Trex can be auto-synced with AMS Device Manager in the field via Wi-Fi or USB.

You can find numerous customer success case studies in the document “How Real Users Benefited from Effective Asset Management” and reach out to the AskPSS team for more.

Visit the AMS section on Emerson.com for more information on device monitoring and health analysis solutions that help you proactively manage devices to drive reliability and performance.