Emerson’s Keith Linsley presented Extract for Emerson Solution for CEMS and Performance Testing in Natural Gas Turbine Applications at the 2025 Emerson Exchange in San Antonio, Texas.

Here is the presentation abstract:

The Natural Gas turbine market is witnessing stunning growth globally to meet energy and electricity demands. In the United States alone, 133 new turbine plants are at various phases of planning and construction. Capacity additions (35,807 MW) outpaced the total capacity retired (15,722 MW) in 2023. This will contribute more emissions to existing aggressive plans to lower greenhouse gas emissions. Limiting global warming to 1.5 degrees C above preindustrial levels requires cutting emissions across sectors by nearly 50% by 2030. Global government agencies continue to add new required emissions measurements at lower detection limits to meet these climate change goals, requiring advanced analytical gas measurement and reporting capabilities through continuous emissions monitoring.

Keith opened by sharing current U.S. Environmental Protection Agency emissions limits regulated under EPA CFR Part 75. These regulations govern facilities generally producing more than 25 Megawatts. The limits include:

- NOx less than 20 ppm

- CO less than 20 ppm

- NH3 less than 20 ppm

Traditionally, gas turbine measurements have required significant costs, including those for NOx and O2 analyzer systems. NO2 must be converted rather than directly measured. NH3 is measured with a dual NOx analyzer with an ammonia converter. There are challenges around converter efficiency and interfering gases. The stack gas cannot be validated and zeroed per EPA PS2 and PS3.

Combined-cycle gas turbines have been used for electric power generation for decades. Existing extractive analyzer technology has been measuring NOx, CO, O2, and CO since the inception of gas turbine power generation.

However, as the required measurement levels and detection limits of CO and NOx have decreased substantially, it has become increasingly challenging for some of these analyzer technologies to measure these components at these low ppm levels, especially in a single analyzer. Most often, these four gas components have been measured in at least three separate gas analyzers at significant cost.

New requirements for compliance have added the measurement of NH3 at levels below 10 ppm, further complicating the issue. The most common method for measuring NH3 accurately has been in situ. Still, this approach is not universally accepted as a global standard for CEMS, particularly in the US, due to a lack of calibration and quality confirmation.

The preferred methodology is complete extractive sampling, but it is problematic at these very low levels in traditional analyzer technologies. Additionally, to provide a complete solution, analytical systems integrators need to bundle multiple analyzer technologies, including volumetric gas flow rate analyzers, with a third-party data acquisition system, bundling it as their own complete, integrated product or packaged solution, albeit at some risk.

Keith explained that Emerson has a solution to measure NO2, rather than converting it to another form. Quantum Cascade Laser (QCL) technology enables direct measurement without interference, eliminating the need for oxidation or an NO2 furnace.

Keith explained that Emerson has a solution to measure NO2, rather than converting it to another form. Quantum Cascade Laser (QCL) technology enables direct measurement without interference, eliminating the need for oxidation or an NO2 furnace.

He compared hot, wet versus cold, dry gas analysis. Traditional analyzers rely on the cold, dry approach. Traditional continuous emissions monitoring systems (CEMS) and process gas analyzers remove moisture with gas conditioners and chillers. Approximately 95% of all CEMS maintenance is attributed to the chiller and the removal of water from the gas sample. QCL technology can work in this mode.

Hot wet analysis is limited to QCL technology. The sample and flow cell remain heated inside the QCL, eliminating the need for a chiller.

QCL Continuous Gas Analyzers can measure up to 12 constituents within a gas with a single analyzer, requiring minimal sample conditioning. Measurements are not affected or damaged by any water vapor in the gas.

QCL analyzers can be used in CEMS, combustion, and other process gas applications. TDL analyzers operate in the near-infrared spectrum, with wavelengths ranging from 800 to 2500 nanometers. QCL expands gas analysis to longer mid-infrared wavelengths (2500-12,000nm). Absorptions are due to fundamental vibrations and atomic bond motion in the molecules. The absorption peaks are more intense and sharper. This high resolution enables the identification of peaks in congested spectral regions, allowing for the measurement of more analytes with excellent cross-interference immunity.

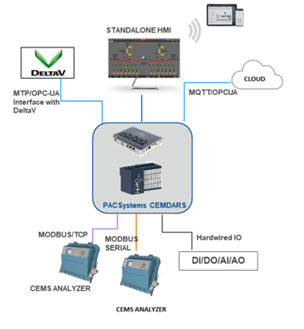

The Emerson CEMS Data Acquisition Handling System (DAHS), which is used to accumulate the data, is based on the PACSystems PLC and an industrial computer. This RX3i PLC is used for data acquisition and control. It communicates with the analyzers via Modbus, TCP/IP, Serial, or Hardwired methods. It manages the sample handling system, calibration gas, and HVAC. An RXi2 industrial PC (IPC) hosts operator screens and a web HMI with multi-browser support.

These screens include a comprehensive summary, featuring graphical health indicators for each component, key emissions metrics for each component, including 20-minute and daily period averages, and are customizable for specific compositions.

It integrates with the DeltaV system via MTP and OPC-UA and can interface with cloud applications via MQTT or OPC-UA.

As a result of advances in spectroscopic analyzers, stack gas flow analyzer advances (Flexim), and DAHS development, Emerson’s measurement and solutions organization now provides all required measurements with minimal hardware in a turnkey, engineered solution featuring maximum Emerson content, thereby eliminating execution risk and responsibility challenges. This pre-engineered solution meets all requirements in the most technically advanced manner, effectively, reliably, and sustainably.

Visit the Quantum Cascade Laser Analyzers section on Emerson.com for more information to help drive more sustainable operations.