There is no question that the rise of renewable energy has complicated operations for power generators and distributors. New technologies mean new devices and lots more data to manage. With each passing year, everything seems to be getting bigger and more complicated.

Emerson’s Sarah Newton and Matt Roberts highlighted this fact in their presentation at the 2025 Ovation™ Users’ Group Conference, illustrating the way system capacity requirements are growing as companies begin to add renewables to their portfolios. They laid out how things are changing, and how forward-thinking companies are proactively using technology to manage those shifts.

“Traditional systems were almost entirely hardwired I/O. As we’ve switched over to renewables, we’ve seen point counts start to rise and we see them transition from hardwired points to digital points.”

Rapid requirement growth

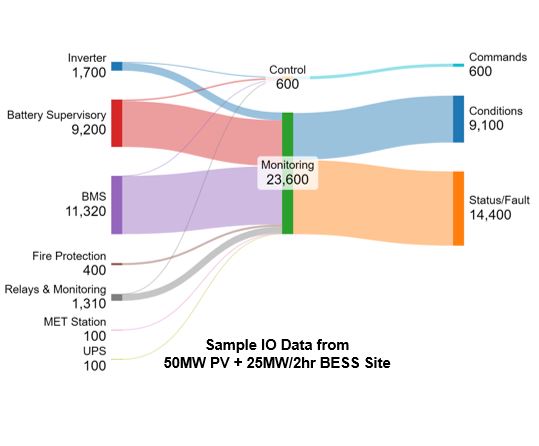

Traditional distributed control system (DCS) and supervisory control and data acquisition (SCADA) system technology is mature and the operations are well known. It’s no surprise, then, that traditional DCS and SCADA are the go-to technologies for coal, gas, and hydro, using primarily hardwired I/O. These operations are still typically local with point counts of about 200 per megawatt (MW) still being relatively common.

As these companies add renewables assets, the data requirements tend to change. Operations for renewables sites tend to be partially or even fully remote, so moving data is even more critical. However, there also tends to be a lot more data. In contrast to the 200 points per MW in a traditional site, renewables often have upwards of 2000 points per MW. Managing ten times the data—and doing so remotely—typically means managing a lot more datalinks.

“The devices themselves are generating tons of data; there’s a lot of data and it’s relatively cheap to create and transmit it. There’s a need to bring it in, whether it’s for warranty purposes or to have on hand for other reasons.”

The changes keep coming

All indicators say that this need for data will only continue to grow. Renewable sites add many data points, with wind, solar PV, and battery sites each adding hundreds of individual devices to the mix. Each of those devices, in turn, creates more data than traditional generation assets. Each device can generate hundreds of data points which are displayed on graphics or historized for warranty purposes and used to feed deeper analysis. This complexity is further increased by the fact that renewables fleets are growing each year.

Much of the challenge is ingesting the data and getting it into the system.

“As our systems grow we need to make sure we can talk to more devices and more points—not just faster, but more granular and more efficiently.”

Know what you need

Part of the journey to success is understanding what data the organization needs, where it is generated, how it makes the trip from the device to where it needs to be—on the plant network or elsewhere across the enterprise—and how much the company wants to invest in infrastructure to support that data. Data scales fast, and needing to manage thousands, hundreds of thousands, or millions of points across a fleet is entirely possible.

Understanding the data requirements will help the team define its data strategy. Prioritizing data in a way that is consumable and manageable is a major part of a successful strategy. For example, as points expand into the highest numbers, some organizations are finding ways to build multinetwork highways to connect multiple systems together across the enterprise, keeping data available at the edge on each network to eliminate the need for all data to travel continuously to and be stored in a remote operations center.

Ovation to the rescue

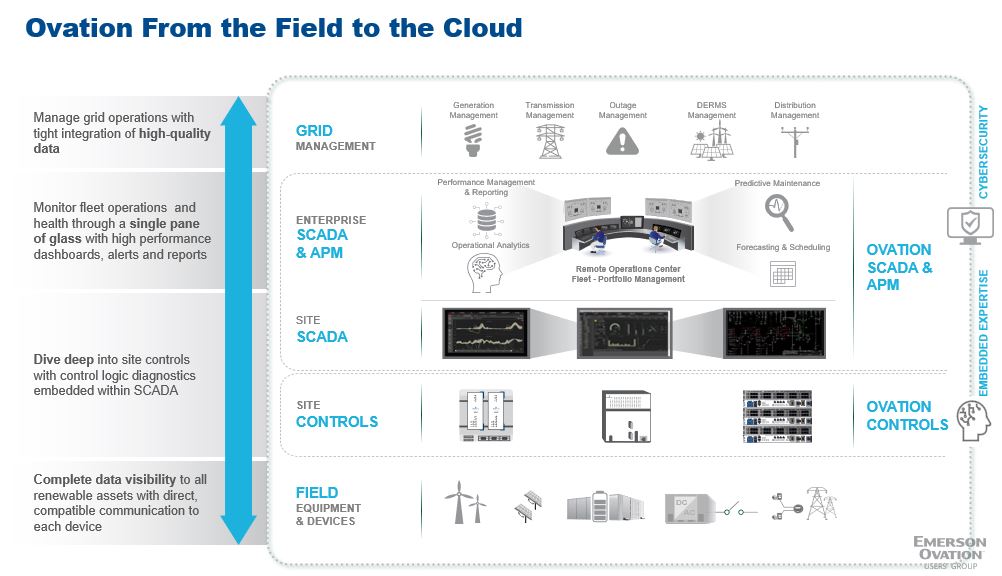

Fortunately, the Ovation Automation Platform is designed with a boundless automation vision in mind, driving flexibility and seamless data mobility from the field through the edge and into the cloud. Matt and Sarah shared many of the technologies that help producers and distributors drive better use of their data to ensure optimal operations.

Grid management tools provide management of generation, transmission, outages, distributed energy resources, and distribution. In addition, Ovation SCADA and predictive maintenance technologies better manage data to drive operational analytics, performance management, forecasting and scheduling, improved maintenance, and reliable remote operations across the enterprise.

Onsite, Ovation controls leverage incoming data to help drive operational excellence and allow operators to dive deep into their site controls with control logic diagnostics embedded within the SCADA system. Making all of this possible is complete data visibility to all renewable assets with direct, compatible communication to each device in the field as well as comprehensive cybersecurity and embedded expertise to allow operators and technicians to perform their tasks with confidence.

Turn big data into big insights

Big data requires big solutions. As organizations continue to increase the share of renewables in their portfolio, there has never been a better time to take advantage of the comprehensive data management benefits of a built-for-purpose control platform. The reliable and scalable Ovation Automation Platform not only leverages Emerson’s six decades of power and water expertise, but also provides the boundless automation foundation to help teams turn their increasingly large data stores into actionable information to drive better operations and increased reliability, as well as to capture competitive advantage.