Desuperheaters play a critical role in many steam processes, spraying water into steam to protect downstream equipment from overheating. The heart of a desuperheater is its spray nozzle, but these nozzles are often installed and forgotten until they fail, resulting in expensive repairs and downtime.

Our article in the May 2025 issue of Automation.com Monthly, titled “How Desuperheater Nozzle Testing Prevents or Predicts Failures,” describes how to create a cost-effective nozzle testing program that can pay for itself many times over.

A critical and sensitive process

Many steam process loops, such as those found in typical combined cycle power plants, use desuperheaters to lower steam temperatures to safe levels. The desuperheating process is highly sensitive, requiring just the right amount of water to be atomized into a fine mist.

An analysis of combined cycle outages shows that most forced outages result from damage to the heat recovery steam generator (HRSG) coils as these usually see the highest temperatures and most difficult process conditions. A common cause of these failures is desuperheaters which either add too little water, too much water, or fail to atomize the water adequately.

HRSG damage occurs quickly and has significant repercussions, costing $2,600,000 USD and four days of downtime to repair on average.

Figure 1. Over temperature damage in pipes from poorly functioning desuperheaters will result in significant pipe and equipment damage, requiring extended outages for repairs.

Nozzle problems

Desuperheater nozzles are designed to distribute a uniform stream of atomized water droplets, but over time they may degrade or plug, disrupting the intended spray pattern and creating water streams that damage piping.

Figure 2. Nozzle plugging or damage can restrict flow.

Clogged nozzles can also severely restrict flow, limiting the desuperheater’s ability to control temperature.

In some cases, erosion can destroy the desuperheater head, allowing water to bypass the nozzle completely, causing catastrophic damage.

A simple solution

Routine inspection and testing of desuperheater nozzles is a straightforward and effective way to avoid the problems described above. Many process plants contract with accredited service providers to perform nozzle flow testing and repairs, either on-site or in local facilities. Implementing a routine nozzle maintenance program is inexpensive compared to the cost of even a single HRSG outage.

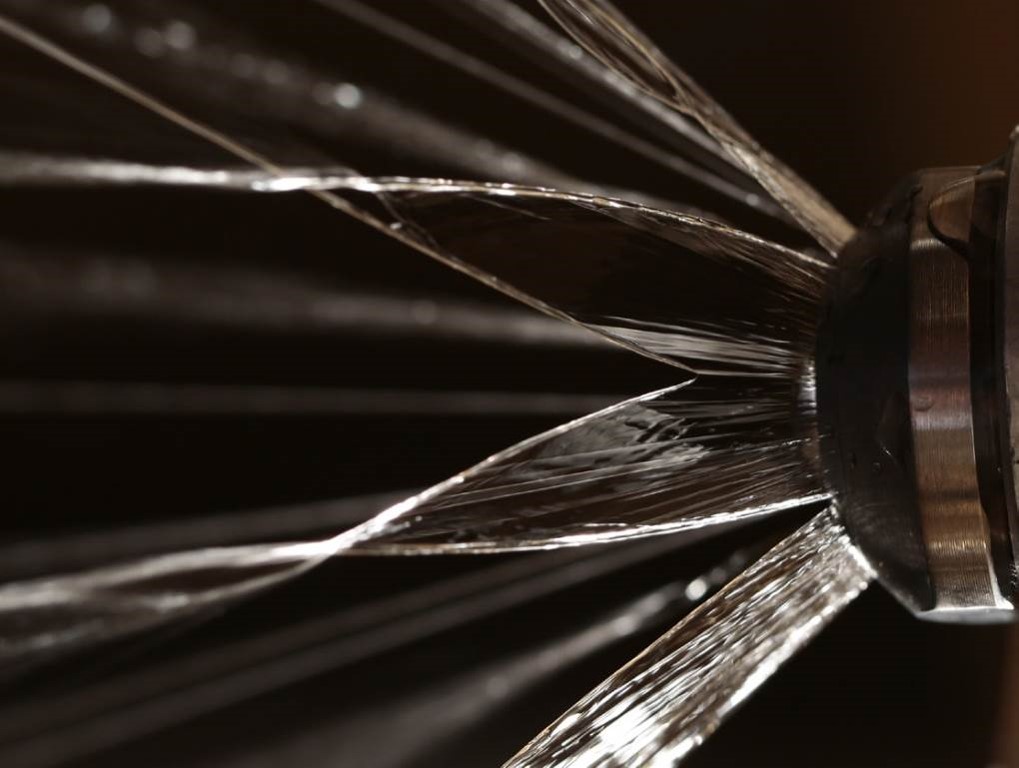

Figure 3. Accredited nozzle repair facilities can bring nozzle flow test stands, like the one pictured here, to the site to check all the desuperheaters in a unit during an outage. Flow testing proves nozzle functionality, and any issues can be addressed quickly.

The cost of nozzle neglect

One power plant noticed the valve responsible for controlling the spraywater to the desuperheater was running nearly fully closed, yet the temperature downstream of the desuperheater was being measured well below specification.

An Emerson Accredited Service Provider suggested the unit be taken out of service and immediately flow tested, but the plant continued to run.

Three weeks later, a weld joint cracked on the downstream piping, causing a 10-day outage and costing the plant $250,000, far more than the $13,000 it would have cost to flow test the nozzles.

Following that incident, the plant discovered that six more of their ten desuperheaters required repairs and/or replacement nozzles. The plant instituted a regular nozzle maintenance routine, preventing future failures and dramatically improving desuperheater performance.

Service providers simplify nozzle testing

Like all mission-critical devices, desuperheater nozzles should be regularly tested and maintained to prevent expensive outages and repairs. Many process plants find it best to contract this task to accredited service providers as they have the equipment and expertise to perform nozzle testing, repairs, and replacements.