Fugitive emissions are the unintentional release of gases or vapors. Countries and regions across the globe have regulations to mitigate the environmental and health effects from these releases.

Here in the U.S., the Clean Air Act, administered by the Environmental Protection Agency, targets volatile organic compounds (VOCs) from industrial facilities. This scope includes valves. The American Petroleum Institute (API) provides specific standards for valves. These include:

- API 622: Tests valve packing for fugitive emissions, focusing on graphite packing for rising or rotating stem valves, with 310 mechanical cycles and three thermal cycles up to 500°F.

- API 624: Applies to rising stem valves, requiring compliance with API 622 packing and a leakage limit of 100 ppm using methane as the test medium.

- API 641: Governs quarter-turn valves using methane and EPA Method 21, with 610 mechanical cycles to simulate a 5-year lifespan.

The European Union has the EU Industrial Emissions Directive (IED) and Regulation (IER), which set limits on fugitive emissions from industrial equipment. Some of these directives include:

- EU Air Quality Directive (2008/50/EC) establishes air pollution prevention standards, requiring compliance with the best available techniques (BAT) to minimize leaks.

- ISO 15848-1: This international standard tests valve stem seals and body joints using helium or methane for fugitive emissions.

Countries have additional regulations to address these emissions and specify consequences for violations.

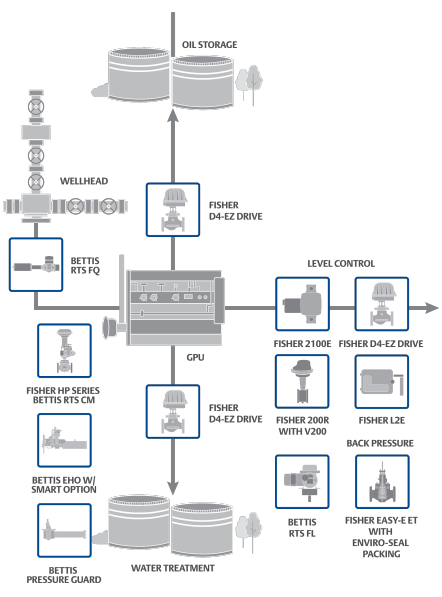

Emerson provides a portfolio of proven fugitive emissions solutions for producers, transporters, and distributors in the hydrocarbon value chain.

Emerson provides a portfolio of proven fugitive emissions solutions for producers, transporters, and distributors in the hydrocarbon value chain.

For example, at the wellheads of an oil & gas producer, electric actuators replacing pneumatic ones can reduce emissions. The Bettis RTS FQ fail-safe quarter-turn electric actuator can provide ball valve safety function on wellhead ESD while eliminating vented methane from valve operation.

The Bettis RTS CM compact multi-turn electric valve actuator for on/off and process control applications enables continuous modulation with configurable speed options. The high-speed modulating performance helps you optimize well control and reduce flaring and emergency shutdown (ESD) events.

The Bettis RS FL linear electric valve actuator provides on/off and modulating control for fail-safe applications around the wellhead. A robust and compact mechanical spring return design triggers the fail-safe operation. It provides gate valve safety functions on a wellhead ESD while eliminating vented methane from the valve’s operation.

The DCMlink software collects data from these electric actuators to enable connectivity to asset management systems. The software helps improve commissioning and troubleshooting and ensures seamless wired and wireless communications with the actuators.

Visit the Bettis brand section on Emerson.com for the comprehensive portfolio of safe, reliable, and field-proven electric, hydraulic, and pneumatic valve actuators.