At the Emerson Exchange 2025 Conference, Emerson’s Chris Vergos, Justin Goodwin, and Shelby Daniels presented Toughest Application Challenges Solved with Severe Service Innovations. Here is their presentation abstract.

Emerson and its Impact Partners assist end users with the specification and selection of the proper control valves for severe service with access to the industry’s most complete line of severe service control valves and accessories. Severe service control valves are used in the most difficult installations within your process plant. These installations commonly include cavitating, erosive, corrosive, noisy, high pressure, high temperature, high pressure drop, or high velocity media. To maximize longevity in these harsh conditions, severe service control valves typically utilize extremely hard materials, materials that withstand temperature and pressure extremes, bodies with special flow paths, bodies with high capacities, and cages with unique flow passages. Get equipped with knowledge about our severe service innovations, such as Fisher™ Whisper™ Trim Technology, Fisher™ Cavitrol™ Hex Trim, and Fisher™ NotchFlo™ Trim.

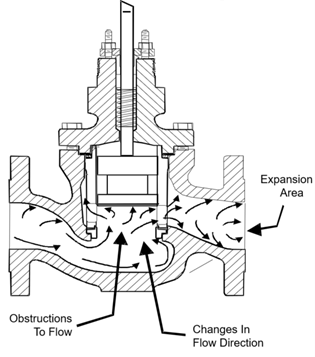

They opened the presentation by discussing noise in control valves. It is a mixture of sound waves of varying amplitude and frequency. These sound pressure levels are measured in decibels (dBA). Turbulence, flow path obstructions, and high-pressure drops create aerodynamic noise in control valves.

They opened the presentation by discussing noise in control valves. It is a mixture of sound waves of varying amplitude and frequency. These sound pressure levels are measured in decibels (dBA). Turbulence, flow path obstructions, and high-pressure drops create aerodynamic noise in control valves.

Gas or vapor flows through a control valve create turbulence, and rapid expansions, flow decelerations, and flow direction changes can also make these sound waves. The turbulence will dissipate downstream, but the noise will continue to propagate.

Ways to address this noise creation are through proper valve sizing, flow and jet separation, and shifting noise frequencies out of the audible range.

Control valve trim helps to control the jet sizes in the flow and maintain jet independence. It can also help to shift the frequency of the sound range out of the audible range.

Next-generation Fisher Whisper Technology includes the new Rotary Vee-Ball Whisper Trim, the new Globe Whisper Trim, and the new Whisper Modal Attenuator technology. The Fisher Whisper NXV rotary valve trim achieves 80% more noise reduction than other rotary valves tested. The Fisher Whisper NGX globe valve trim achieves 20% more capacity than other globe valves without compromising noise attenuation capabilities. The Fisher 6060 WhisperTube Modal Attenuator provides full-bore noise attenuation with no pressure drop or impact on the process.

They shared three applications for Whisper technology, including a gas treatment skid, a cool and reheat steam valve, and a natural gas utility monitor station. For the gas treatment skid, the challenge was to avoid exceeding the 80 dBA limit, as the existing trim was unable to achieve this level of noise reduction. An NPS 6 Fisher Vee-Ball with Whisper NXV was able to achieve the required noise reduction and offer a smaller footprint than the next best solution, an NPS 8 globe valve.

They shared three applications for Whisper technology, including a gas treatment skid, a cool and reheat steam valve, and a natural gas utility monitor station. For the gas treatment skid, the challenge was to avoid exceeding the 80 dBA limit, as the existing trim was unable to achieve this level of noise reduction. An NPS 6 Fisher Vee-Ball with Whisper NXV was able to achieve the required noise reduction and offer a smaller footprint than the next best solution, an NPS 8 globe valve.

For the power plant’s cool and steam reheat valve, the challenge was low flows, which caused leakage issues, wasted steam energy, and poor downstream control. They were experiencing vibration due to high noise levels, which caused accelerated damage. An NPS 4 Fisher ED valve with Whisper NXG improved controllability and prevented damage from low flows.

The natural gas utility monitoring station was challenged by noise levels of up to 100 dBA caused by non-Emerson ball valves. The solution was to use Fisher regulators with Whisper trim paired with a Fisher WhisperTube.

These solutions saved space and capital outlays without compromising noise reduction levels.

Cavitation is another serious problem. This can cause erosion and hydrodynamic noise, which may affect the valve’s life. Cavitation is caused by a rapid phase change from liquid to vapor and back to liquid. As pressure drops through a restriction, it falls below the vapor pressure, and vapor bubbles form. As pressure is recovered, the vapor condenses back into a liquid, and high-speed, destructive micro-jets form.

In control valves, cavitation is addressed through the use of isolation and pressure staging. Isolation directs where cavitation will occur and uses hard/tough materials to withstand the abuse. However, with this approach, noise and vibration are still concerns.

Pressure staging uses discrete, low-recovery pressure stages with engineered recovery zones. By reducing or even eliminating cavitation, the associated noise and vibration are also reduced or eliminated.

Below are some Fisher Anti-Cavitation solutions.

Some case studies shared for addressing cavitation included a refinery’s gas blending tank level control valve, a coal-fired power plant’s reheat spray water valve, and a supercritical power plant’s boiler feed pump recirculation valve.

The refinery was challenged with cavitation and severe vibration on its gas blending tank level control valve, which accelerated damage to the valve and surrounding piping. By applying a 4-inch V150 with Cavitrol Hex trim, they were able to alleviate erosion and vibration damage, thereby increasing overall reliability.

The coal power plant experienced cage plugging and trim erosion caused by cavitation. This condition led to issues with temperature control. Installing a 4-stage Dirty Service Trim (DST) retrofit in the 2-inch reheat spray water valve body prevented cavitation and erosion while passing the particulates present in the flowing media.

The boiler feed pump recirculation valve experienced extreme cavitation erosion, leakage, and pipeline vibration, which fatigued the deaerator’s inlet piping and bolting. Installing an NPS 6×8-inch Fisher EHT control valve with CAV4 Trim prevented cavitation through the pressure staging, which minimized leakage and vibration.

Their presentation also shared examples of custom-engineered Fisher solutions for the most difficult and critical applications, such as:

- Dirty fluids or entrained particles

- Extreme temperatures

- Severe cavitation

- Special noise attenuation

- Attemperators/Desuperheaters

- Ultra-high pressures

- Outgassing and two-phase flow applications

- Highly viscous fluids

- Erosive fluids

- Highly corrosive fluids

- …and more.

Visit the links above and the Severe Service Control Valves section on Emerson.com for more on solutions to your toughest process challenges.