Emerson’s Andrew Cureton presented Don’t Overthink It–Wireless for Chemical Industry MON Mandate Compliance at the 2025 Emerson Exchange Conference. His session explored the monitoring requirements of the U.S. Environmental Protection Agency rules for pressure relief valves. Here is Andrew’s presentation abstract.

Can wireless sensors be used to meet EPA monitoring requirements? It sure would eliminate a lot of the project cost for conduit and wiring. For the US chemical sector, the “MON Mandate” by the EPA required operators to put sensors on relief points protecting against hazards air pollutant releases. Dozens of Emerson users decided that wireless sensors are all they needed to come into compliance making their retrofitting projects quickly and affordably – and in many cases even non-intrusive. Last year this applied to the chemical industry, but legislators have been rolling this out from industry to industry, so yours might be next.

Andrew opened by defining the U.S. Environmental Protection Agency’s 40 CFR Part 60 regulations known as the National Emissions Standards for Hazardous Air Pollutants (NESHAP) Compliance Monitoring. Part 60 addresses the Standards of Performance for New Stationary Sources. This is known as the “MON Mandate” for organic chemical manufacturers. MON is the acronym for “Miscellaneous Organic Chemicals Manufacturing NESHAP.

Pressure relief management requirements are found in many of the CFR 63 subparts, including CC, DD, YY, JJJ, MMM, OOO, PPP, FFFF, and GGGGG. The regulations require the identification of pressure relief events, recording the time and duration of these releases, and notifying the operations staff immediately about a relief event.

40 CFR 63.2480, Subpart FFFF, deals with the requirements for addressing equipment leaks. Pressure relief devices must have monitoring to record the time and duration of a release, along with an immediate notification to plant operators. Alerts and EPA notifications are separate steps and don’t have to occur simultaneously.

Organic Hazardous Air Pollutants (HAP) in MON is a liquid or gas that contains 5% by weight total organic HAP material, including Benzene, 1,3-Butadiene, Cumene, Ethylbenzene, and Ethylene oxide. Ethylene oxide must comply with regulations at any level.

Challenges to compliance include budget, time, and knowledge. It requires familiarity with the regulations, identifying affected release points, qualifying and selecting monitoring solutions, planning and coordinating procurement and deployment times, accessing difficult locations, cutting pipes, replacing valves, and validating performance.

Pressure relief devices include standard pressure relief valves, rupture disc-protected relief valves, rupture discs only protected release points, vent hatches, and P/V valves. Traditional pressure measurements exhibit peaks and valleys, making it challenging to determine when the pressure relief valve (PRV) is actually open or closed. Also, conditions like valve simmering or chattering can miss the ongoing leakages.

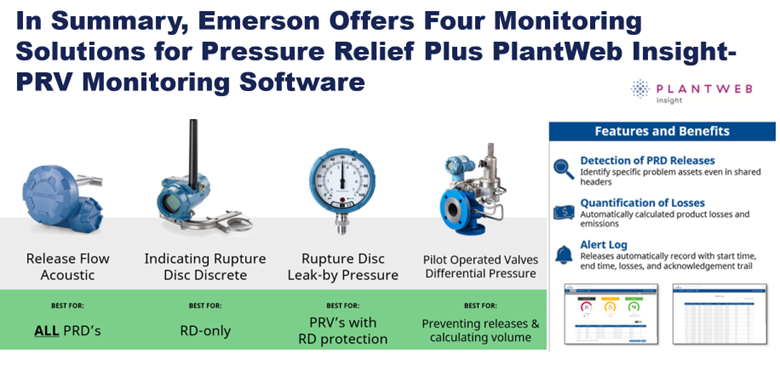

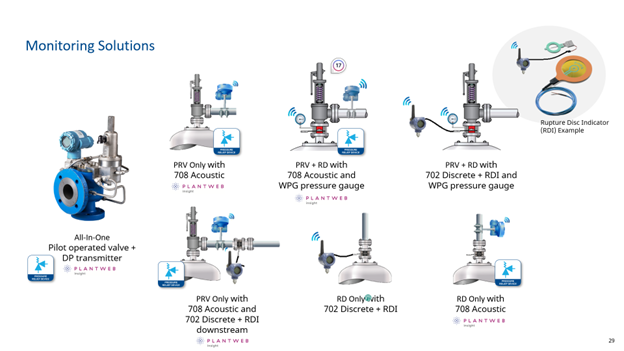

Wireless devices can provide monitoring that can simplify installation and be installed in difficult locations. Four monitoring solutions are available for these pressure relief devices.

Here is a look at all the monitoring solutions.

A Rosemount Wireless Pressure Gauge can detect and react to rupture disc failure before the situation becomes critical. A Rosemount 702 Wireless Discrete Transmitter can detect an approach to a ruptured disc. The Rosemount 708 Wireless Acoustic Transmitter senses acoustic energy generated by the turbulence caused by fluid passing the PRV’s valve seat. It detects this acoustic energy by contacting the wall of the pipe.

The Plantweb Insight Pressure Relief Valve application helps automate and eliminate the guesswork for pressure relief valve (PRV) monitoring. The application provides an indication of PRV releases, including start and end times, as well as production and emissions losses. Event log records are also automatically generated for one year for EPA reporting. Plantweb Insight uses machine learning-based asset models and analytics and easily integrates with existing infrastructure.

Visit the links above for more on these solutions to help your pressure release compliance efforts.