Even casual fans of old-school superheroes know that Superman’s X-ray vision gives him the ability to see through solid walls (although maybe not lead), leaving criminals unable to hide from him. No doubt many process engineers and technicians wish they had such a...

Posts by or with William Fazackerley

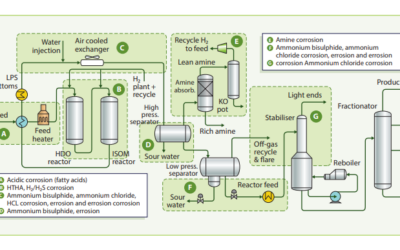

Managing Biofuel Processing Corrosion Risks

In a Decarbonisation Technology article, Managing corrosion risk in SAF and renewable diesel processes, Emerson’s William Fazackerley describes how non-intrusive real-time corrosion monitoring provides early warning of corrosion issues to enable early mitigation actions.

Advancing Non-Intrusive Corrosion Measurement in Modern Refinery Operations

As refineries navigate an increasingly complex operating environment, the challenge of managing corrosion risks while maintaining operational flexibility has become paramount. Emerson's Rosemount™ Wireless Corrosion and Erosion Transmitters, with over a decade of...

Navigating Corrosion Hotspots in Amine Units: A Guide for Refineries and Gas Processing Plants

Amine units are critical components in refineries and gas processing plants, removing acidic contaminants like H2S and CO2 from process streams. However, these units are particularly vulnerable to corrosion, which can lead to costly shutdowns and safety risks. Let's...

How to Monitor the Effects of Sand Erosion at Oil and Gas Production Sites

When it’s time to repaint the ironwork of a bridge or building, what’s the best way to strip away old paint and rust? Sandblasting is usually the first choice because it is very effective at eroding surface crud and getting down to clean metal, but if it continues too...

Managing Equipment Damage Caused by Corrosive Feedstocks Encountered with Biofuel Production (Part 2)

When we talk about renewable fuels to the general public, many might imagine cars running on gasoline made from wildflowers and meadow grass. However, those who work in the industry recognize that the fats and oils used to make renewable diesel can be just about...

Managing Equipment Damage Caused by Corrosive Feedstocks Encountered with Biofuel Production

When we talk about renewable fuels to the general public, many might imagine cars running on gasoline made from wildflowers and meadow grass. Those who work in the industry recognize that the fats and oils used to make renewable diesel can just about be anything but...

Solving Corrosion Problems by Treating Metal Deterioration as a Process Variable

Imagine that you’re called into your plant to solve a recurring problem. The operator states: “We’ve had to replace this valve three times this year due to failures from over pressure.” Your first question is pretty obvious: “How high is the pressure?” The operator...

5 Key Factors to Consider Before Investing in a Corrosion Monitoring Solution

Introduction If you are reading this, then it’s likely that you are considering investing in an ultrasonic thickness corrosion monitoring solution to improve visibility into the health of your facility. Now that you’ve decided there is a compelling reason to install...

Optimise Plant Performance in Chemical Facilities Using Continuous Integrity Monitoring

Continuous corrosion monitoring offers the granularity, accuracy, and reproducibility that traditional periodic monitoring methods such as manual inspection do not. Using these traditional methods mean it is impossible to link corrosion incidents to asset integrity, which leads to chemical operators acting reactively rather than proactively.

Managing Localised Corrosion Using Online Wall Thickness Monitoring

Wireless non-intrusive corrosion monitoring technology can reliably be used to detect localised metal loss, which offers early detection of corrosion or erosion events as well as validation that mitigation strategies are adequately controlling corrosion and erosion.

Managing Unknown Corrosion in Carbon Capture and Storage Facilities

Carbon capture and storage (CCS) or utilization (CCU) of captured carbon dioxide (CO2) are tools for reducing global carbon emissions, but with new technologies come new challenges. Learn about potential risks with CCS and CCU, and how they could be mitigated using modern sensor technology.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.