The Fisher FIELDVUE DVC7K digital valve controller offers Advice at the Device technology with real-time analytics for valve health diagnostics and prescriptive corrective actions. In a ControlGlobal.com article, Advice at the device—and remotely, Emerson’s Tom Brandau is quoted on the history of digital valve controller technology.

Emerson

Decarbonizing Heavy-Duty and Commercial Transport with Hydrogen Fuel Cell Technology

Heavy-duty and commercial transport are notorious for their significant contribution to greenhouse gas emissions, particularly in the European Union, where they account for a staggering 27% of total road transport emissions. However, there’s a promising solution on the horizon that’s set to revolutionize this sector – hydrogen fuel cell technology.

Augmented Reality

Silvia Gonzalez explores how Emerson Movicon.NExT™ augmented reality (AR) technology is revolutionizing human-machine interfaces (HMI) and supervisory control and data acquisition (SCADA) systems. The article highlights how AR interfaces, delivered through devices like tablets and AR goggles, empower industrial operators in various ways. Operators can follow step-by-step instructions, receive training, and access data from hazardous areas safely.

Exploring the Ways to Improve the Efficiency of Solenoid and Miniature Valves for Homecare and Portable Medical Devices

In the realm of home care medical devices, a remarkable transformation is underway, powered by the seamless synergy of cutting-edge flow-control products and expert engineering provided by valve suppliers.

Accelerating Hydrogen Infrastructure: Key Insights in Our Whitepaper

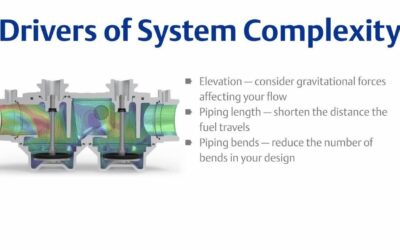

Hydrogen-fueled vehicles are on the rise, necessitating the development of reliable and efficient hydrogen fueling stations. However, scaling up such infrastructure poses unique challenges that require innovative solutions. In our new white paper, “How to Effectively Control Flow of Hydrogen Fuel to Improve Safety, Reliability, and Fueling Rates at Dispensing Stations,” we delve into these challenges and explore potential solutions for scaling hydrogen fueling infrastructure.

The Top 4 Key Performance Indicators (KPIs) to Improve Your Next Outage

Capturing the performance of the overall outage, measuring the effectiveness of the strategy, benchmarking for maintenance and reliability comparisons, and updating the customers’ documentation are crucial to the success of future events and plant operations between them. If overruns occurred, the source of those overruns should have already been approved prior to execution but should be part of the review process as well. This will be fed into the lessons learned documentation.

Gas Control for Laser Cutting

In the world of laser cutting, where precision is paramount, engineers rely on direct acting proportional regulators to achieve rapid system changes and maintain the quality of cuts. One area where proportional control is crucial is the gas assist system.

How Automation Can Help End Users and Device Manufacturers Scale Up the Clean Hydrogen Economy

Hydrogen fuel technology has reached a stage where it is past the prototype phase, and the industry is now looking to scale up. The fuel cell market, for instance, is forecast to grow at a robust 45.3% compound annual growth rate between 2022 and 2029, with projections of a market value reaching $17.88 billion. However, the potential growth of the industry is not guaranteed. There is still much work to be done, including increasing fueling stations and reducing the cost of producing green hydrogen. To mitigate risks and help hydrogen technology mature, strong partnerships between innovators and automation experts are needed. Automation experts can help hydrogen OEMs and end-users scale up capacity to meet market demands, keep projects on time and in budget, monitor hydrogen application performance, and ensure safety in volatile environments. With the help of automation experts, the hydrogen market can scale up and make a significant contribution towards achieving ambitious climate goals.

Three Simple Steps To Improve Gas Train Performance

Designing a fuel train system for a boiler, furnace, or oven requires careful consideration of various parameters. Flow is one of the key parameters that should be maximized to ensure optimal performance of the burner and prevent potential shutdowns due to low fuel pressure. However, poor flow in the fuel train can be a common issue, which can be addressed by selecting the right components.

The Advantages of Digitalization in Clean-in-Place Systems

Clean-in-place (CIP) systems are a vital part of daily production in the food and beverage industry. They allow manufacturers to clean internal piping, tanks, and machines from one batch to the next to meet government regulations and ensure product quality and safety. However, CIP operations also represent a significant portion of a facility’s total utility costs and often involve manual process adjustments and manual data recording.

Solve Joining Challenges as Device Manufacturers Moving Away from PVC and PC

Are you stuck with the joining challenges of modern device manufacturing? As device manufacturers move away from polycarbonate (PC) and polyvinyl chloride (PVC) resins, they face a unique set of challenges when it comes to joining the new materials. Some traditional...

Retaining Talent: Creating an Engaging Company Culture

By having a clear purpose and making sure that it aligns with their employees’ values, they can attract and retain top talent. It’s a challenge, but if companies can make it happen, they’ll be in a much better position to keep their employees happy and engaged.

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.