One of the challenges expressed by lithium battery manufacturers is that they have to be fast and agile because each of their customers may have different formulations for the cathode, anode, and electrolyte material.

Sung Heon Lee

Improving Quality in Midstream Lithium Production

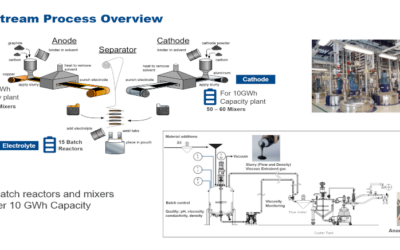

The midstream part of the lithium value chain involves manufacturing the Cathode, Anode, Electrolyte, and Separator. We will focus on the cathode, anode, and electrolyte in this series of posts. The process for making the Cathode, Anode, and Electrolyte is very similar. The process involves batch reactors and mixing.

Solving Battery Production Growth Challenges

The growth of lithium-ion battery production for electric vehicles will occur in mining, battery component manufacturing, and battery cell production from an automation standpoint.

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.