Despite numerous advancements to digital valve controllers in recent decades, their local user interfaces and connectivity options have remained somewhat limited. My article in the August 2024 issue of Process Industry Informer, titled “Digital Valve Controller...

valve

How Data-Driven Reliability Improvements Can Streamline Maintenance And Cut Costs

Advanced monitoring solutions provide real-time information and actionable insights that empower predictive maintenance strategies that lead to reduced downtime and help prevent quality issues.

Using Control Valve Diagnostics to Optimize Turnaround Planning, Testing and Execution

During the Emerson Exchange EMEA 2024, Chand Basha Chittoor, staff engineer E&A at the SABIC Centre of Excellence in the Kingdom of Saudi Arabia, informed delegates how the company optimized turnaround planning and execution using control valve diagnostics.

Power Industry Valve Application Video Series

Valves are critical in many power industry applications such as boiler feedwater & recirculation, superheat attemperation, turbine bypass, and more. In this YouTube Fisher Valves & Instruments Power Industry Application Series, you can learn about the role...

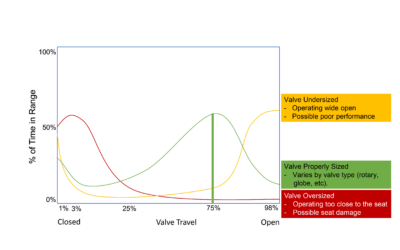

Finding the Value in Control Valve Data

In a world awash with digital data, many tend to assume that more data equals more value, but the reality is that data only becomes valuable when it is analyzed and acted upon. In my article titled “Transforming Valve Data into Dollars,” published to Automation.com in November 2023, I discuss a new software application that converts raw control valve data into actionable information.

Pneumatic Controllers Revived by Flexible, Configurable, Digital Process Controller

Emerson’s Fisher Instruments has been producing its Wizard pneumatic controllers since the 1940s, refining and revamping them every 20 years or so. Along the way, the company produced its electro-pneumatic controllers, and more recently developed its Fisher™ FIELDVUE™ digital pneumatic controllers (DPC). In all, Emerson estimates there are more than 1 million of its pneumatic controllers presently operating.

Take Your Turnarounds to the Next Level

Plant turnarounds have never been known to be staff’s favorite projects, so few people were sad to see them slow or even stop altogether during the COVID pandemic. But now that the worst of the global pandemic appears to be in the rearview mirror, organizations have...

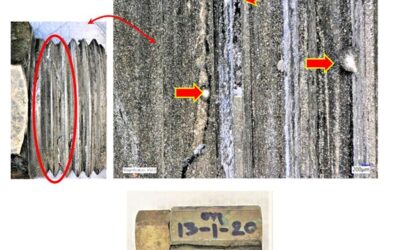

Careful Valve Material Selection Prevents Premature Failures

In refineries and petrochemical plants, frequent contact with process media can result in premature corrosion of valves and related components. To help prevent this, vendors can provide expert advice and, in some cases, lab testing to verify compatibility between...

Advice for Choosing a Valve Service Repair Company for Your Next Outage

Choosing a valve maintenance company that you can trust is difficult. During a shutdown or outage, you want your plant back up and running as quickly and safely as possible, while staying within budget and completing reliable repairs. Here are some tips from an...

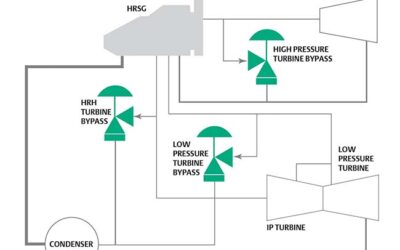

Control Valve Selection for Turbine Bypass Applications

Turbine bypass valves are subject to frequent thermal cycles, high pressure drops, and the need for tight shut off. My article in the May 2023 issue of Power, titled "Turbine Bypass Valve Challenges,” provides methods of inspection to prevent their failure. Surviving...

Three Steps to Maximize Your Next Outage with a Data-Driven Valve Maintenance Strategy

Planning for your upcoming planned outage can be aided by this report. If an unanticipated outage occurs, you can review the most recent report to find out which valves might need to be fixed. When planning for the next outage, you will have a priority ranking of valves based on which are the most critical to be serviced. As a result, you can properly prepare for the extent of service and the parts required for the outage. If you are able to complete the planned valve service scope early, you will already know which valves to examine that are second most important to be serviced. Most importantly, you can prevent opening and removing valves that are not in need of maintenance during a planned maintenance event.

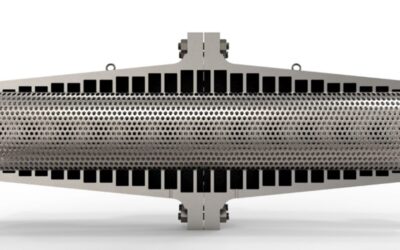

Cutting Control Valve Noise

The modal attenuator consists of a series of carefully engineered resonant cavities to provide sound reduction across a wide spectrum of frequencies. The full-bore design allows unrestricted flow, and internal drain channels drain off condensate which could build up in the device and reduce performance. Installed just downstream of the valve, the modal attenuator achieves an overall sound reduction up to 15 dBa, while creating no restriction in flow capacity whatsoever. The device can be used on existing valves or paired with a low noise control valve to achieve even higher levels of noise reduction. Unlike diffusers or silencers, the modal attenuator works consistently across a wide range of flow rates.

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.