In a world awash with digital data, many tend to assume that more data equals more value, but the reality is that data only becomes valuable when it is analyzed and acted upon. In my article titled “Transforming Valve Data into Dollars,” published to Automation.com in November 2023, I discuss a new software application that converts raw control valve data into actionable information.

The evolution of analytics

Not too long ago, strip chart recorders were state-of-the-art tools in data collection and analysis. In the 1980s and continuing into the 1990s, IC chips became increasingly powerful and affordable, and the data revolution began in earnest. Newly available diagnostic information gave technicians greater insight into the causes of device failures than ever before.

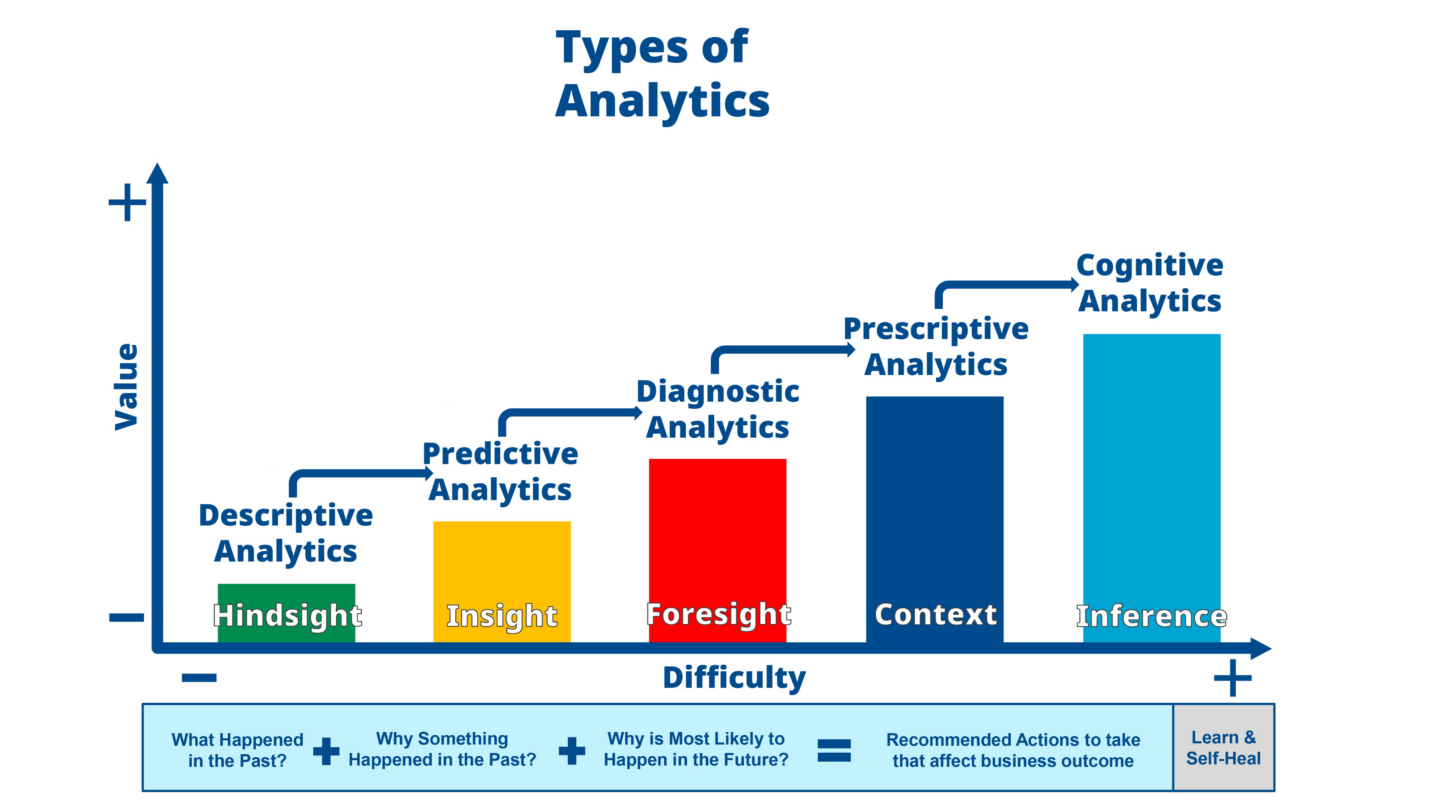

Across the last four decades, the increasing power of electronics and shrinking size and expense of sensors has enabled progressively higher levels of analytic capability.

With the arrival of the new millennium came a host of digital communication protocols, facilitating data transmission from field devices to central host systems. The ever-growing stream of data made it possible to not only diagnose device failures, but to begin predicting failures in advance.

To this day, each new electronic innovation, from embedded sensors to Bluetooth® wireless technology, increases data volume and accessibility. The problem is few plants have the resources to perform the level of analysis needed to make full use of all this data. Fortunately, new software solutions are poised to address this issue.

Next-generation valve data analytics

Predictive analytic software programs, such as Emerson’s Plantweb Insight™ Valve Health Application, constantly monitor and evaluate incoming field device data to identify trends, developing problems, and impending failures. Taking these insights one step further, the application provides not only predictive but also prescriptive analytics—actionable suggestions to correct issues.

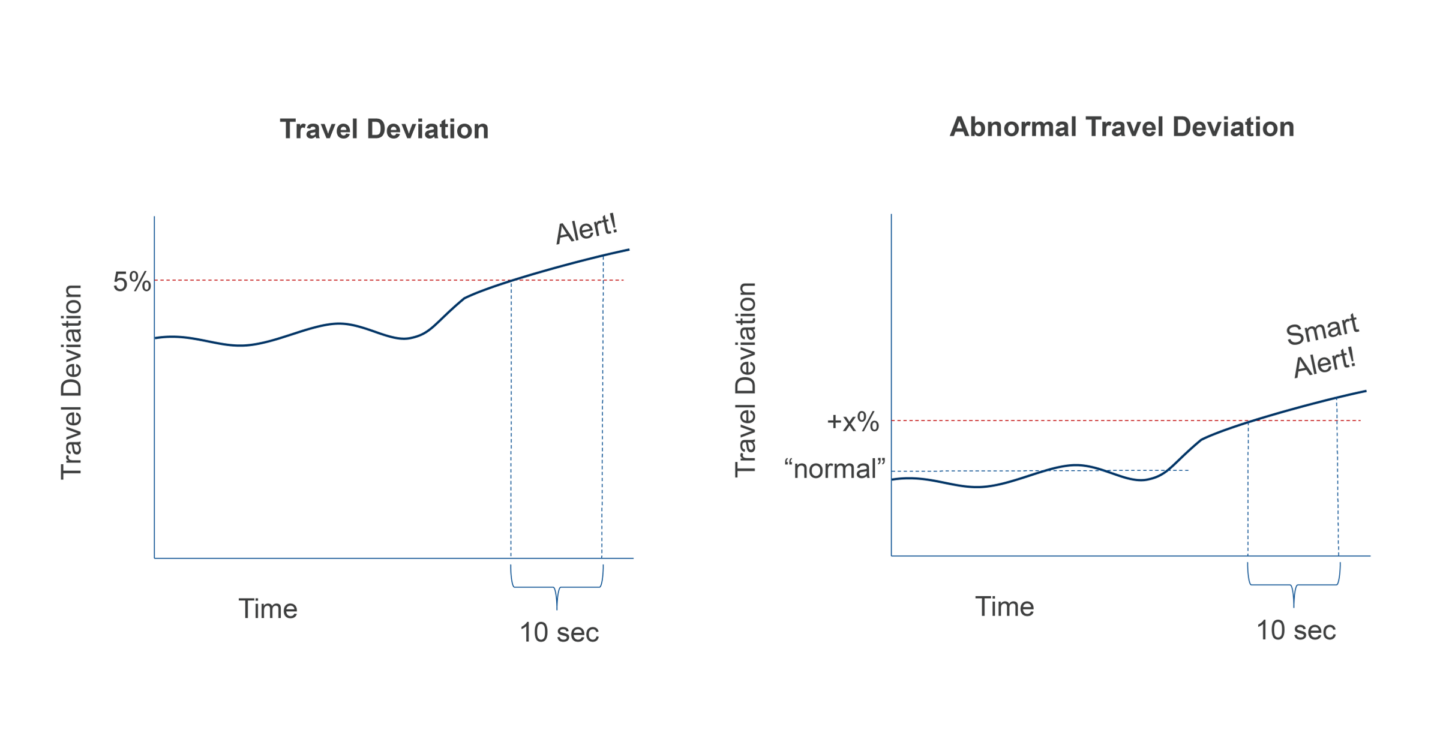

Basic analytic software (top) generates an alarm on a fixed deviation after a delay. More advanced software (bottom) incorporates the historical performance of the valve to accurately identify the exact issue and suggest a solution.

Unlike previous software, which used fixed deviation setpoints to trigger alarms, Valve Health Application employs a smart alert system that takes historical valve performance into account to detect problems more accurately, reducing false notifications. It also identifies poorly performing valves by monitoring valve position over time.

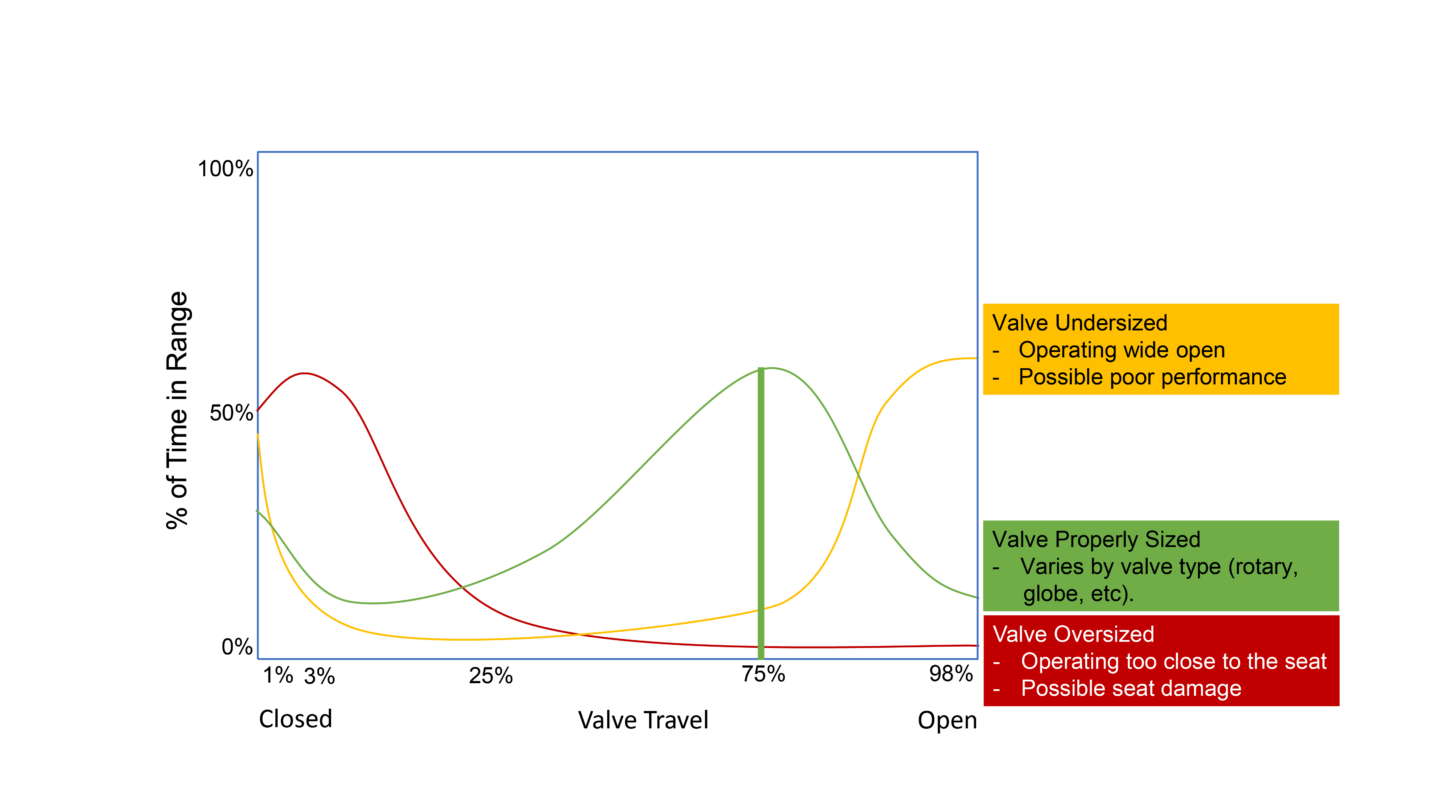

Analysis of the amount of time a valve operates within a particular range can identify over or undersized valves, and then predict eventual seat damage or process limitations due to restricted flow.

Historical performance data is also utilized to predict when a device will ultimately fail. For instance, a valve may start sticking due to coating of process solids. By monitoring the rate of travel degradation and required increased air pressures on the actuator, the software can predict how long plant personnel have before they need to pull a valve for service, well in advance of when its performance would begin to impact the process.

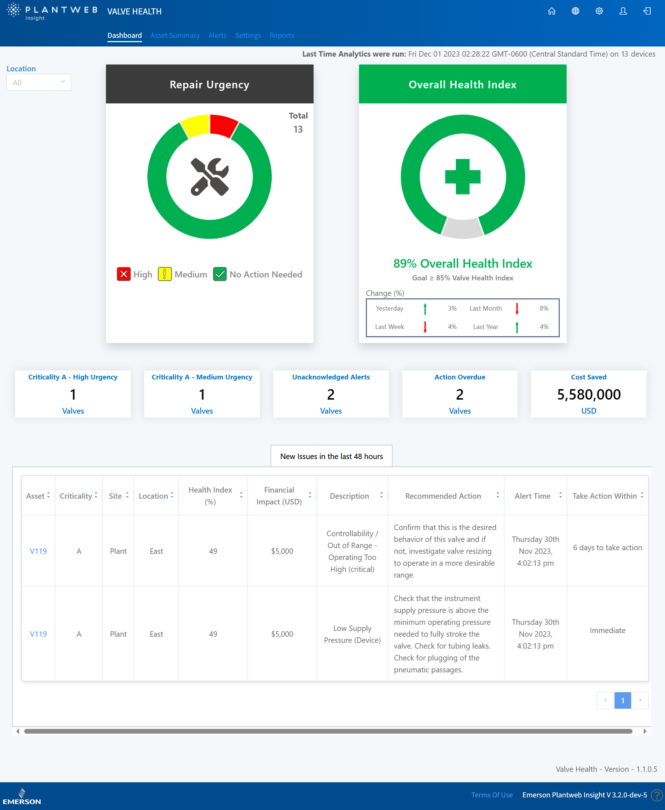

Users can quickly gauge the health of an entire valve network through a simple dashboard. Problematic valves are clearly highlighted, with more detailed information and suggested remedies readily accessible.

The Plantweb Insight Valve Health App dashboard empowers users to evaluate the entire plant, and even multiple plant locations. Site, unit, and device specific screens are available. Users can easily navigate directly from the overall plant dashboard to drill down and examine details of individual valves.

Putting valve data to work

The sea of data generated by valves in modern plant systems can be overwhelming, but advanced analytic software can convert this data into clear, actionable insights, increasing safety and process reliability. Contact your local Emerson office or Emerson Impact Partner to learn more.