Despite numerous advancements to digital valve controllers in recent decades, their local user interfaces and connectivity options have remained somewhat limited. My article in the August 2024 issue of Process Industry Informer, titled “Digital Valve Controller Connectivity Improvements,” discusses how the next generation of digital valve controllers expands user interface capabilities and connectivity features to address this and other issues.

Past connectivity constraints

The earliest electro-pneumatic valve positioners were black boxes, offering little indication of their status beyond a few local pressure gauges. Technicians had limited capability to troubleshoot the device other than measuring the incoming 4-20mA signal and comparing it to the control valve’s physical position.

The advent of HART technology provided essential device configuration and status access, but technicians still had to physically connect to the 4-20mA loop, which was often difficult in hard-to-access and hazardous locations. Next-generation digital valve controllers address these shortcomings by providing a wide selection of local, remote, and wireless connectivity options.

Local interface improvements

These new controllers feature an extensive local interface that gives users access to device information, and to troubleshooting diagnostics and recommendations. The interface also provides intuitive configuration and calibration procedures that can be completed without opening the device. These tasks can all be accomplished without permits or restrictive operating procedures, even in hazardous areas.

The latest generation of digital valve controllers (Fisher™ FIELDVUE™ DVC7K shown) features a fully functional display, providing access to device information, diagnostics, and configuration in multiple languages

Expanded HART communication

Because HART remains a viable means of device access and configuration, next-generation digital valve controllers continue to support, and even expand, the amount of information accessible via HART. This information includes an extensive history of sensor data and alerts, facilitating troubleshooting and root-cause analysis, even months after an event.

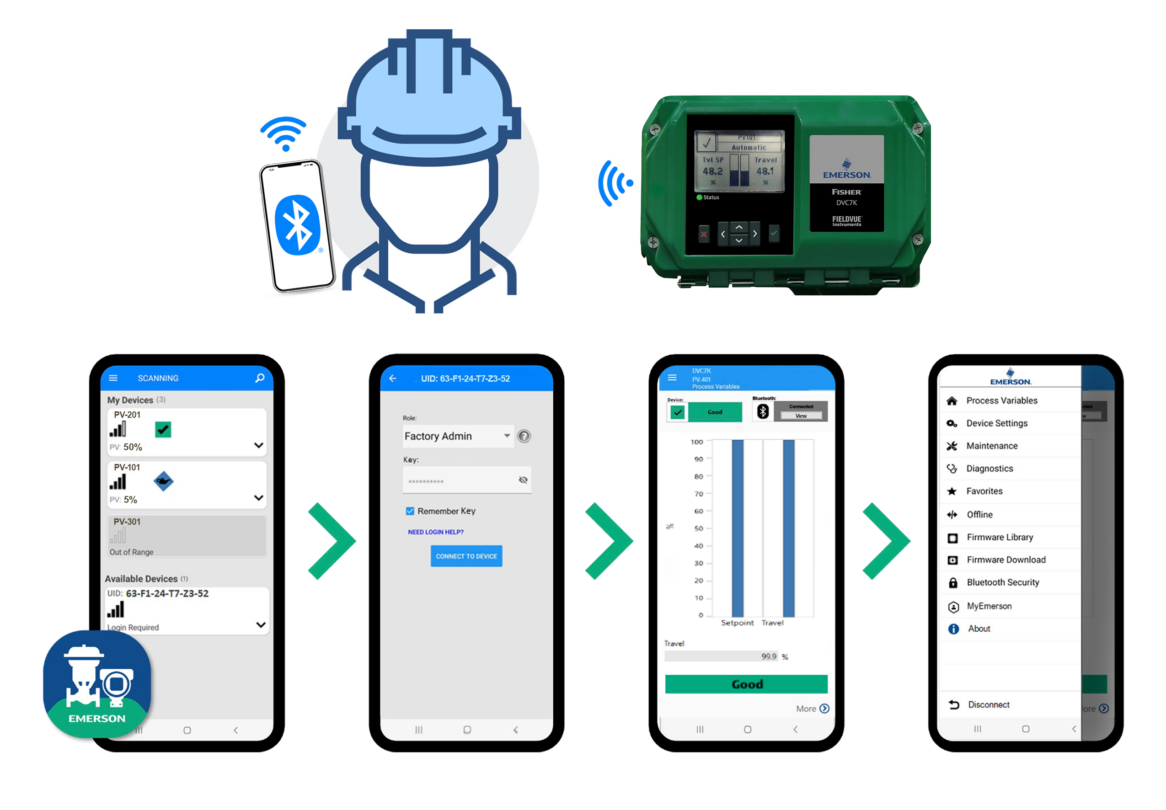

Secure Bluetooth® connection

Bluetooth technology offers high-speed wireless connectivity, but adoption in field devices has been limited by cybersecurity concerns in the past. However, with the development of secure Bluetooth protocols, including Emerson’s Secure Bluetooth® Wireless Technology, an increasing proportion of new field devices are incorporating these communication capabilities, including the next generation of digital valve controllers.

Bluetooth communications offer high-speed local communications without opening device covers, however there are cybersecurity issues associated with these remote connections. Recently introduced protocol revisions, such as Emerson’s Secure Bluetooth Wireless Technology, provide safe use of this technology.

Simple software access

Whether the communications are established through HART or secure Bluetooth, there are a host of software applications available to take advantage of the advanced diagnostics, new sensors, and predictive analytics being incorporated into the next generation of digital valve controllers.

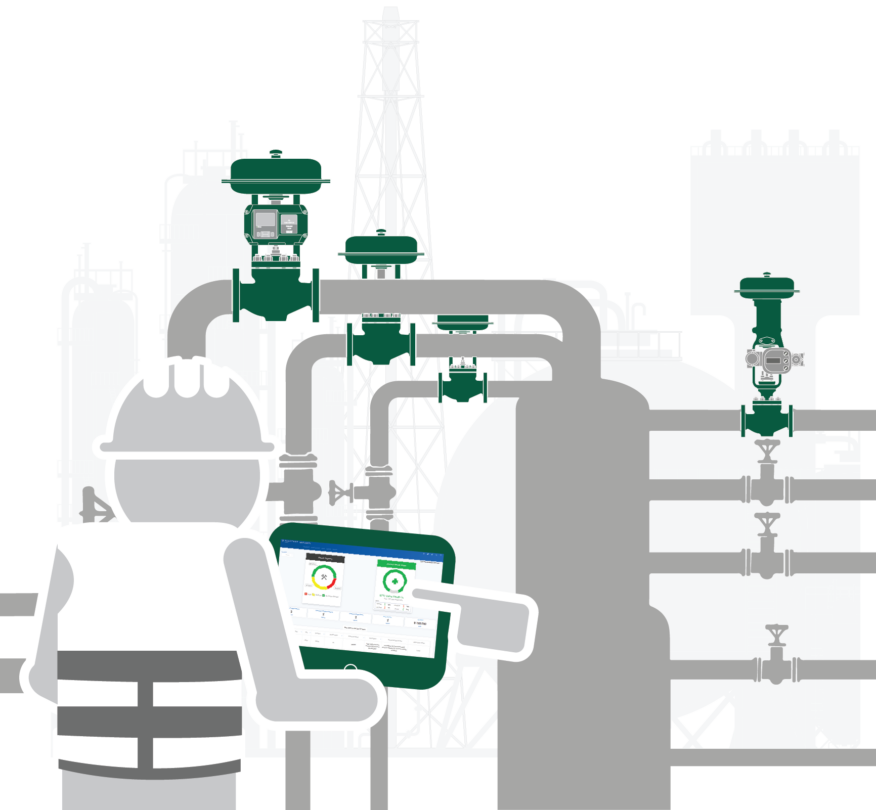

These applications run on local or cloud-based servers and are accessible via digital devices, including cell phones, tablets, and laptop computers, facilitating comprehensive and convenient valve monitoring for an entire plant. For example, the new Plantweb Insight™ Valve Health Application uses wired or WirelessHART communication to remotely monitor the health of a full fleet of connected valves.

New valve health applications incorporate analytic algorithms and advanced diagnostics to detect existing and developing valve problems. Alerts are prioritized so users can focus on the most pressing problems.

Through HART, Bluetooth, and local interfaces, next-generation digital valve controllers dramatically improve ease of access, configuration, monitoring, and troubleshooting, empowering plant personnel to increase uptime, reduce maintenance costs, and improve overall valve performance.

Visit the Digital Valve Controllers section on Emerson.com to know how you can meet your process reliability and performance goals by bringing intelligence to your entire valve assembly. You can also check out the Fisher™ FIELDVUE™ DVC7K Digital Valve Controller product detail page as well as the product 360 demo.