I had the chance to catch up with James Beall while he was here in Austin for meetings. You may remember James from an earlier post of a refiner in dire need of process stabilization assistance.

James will be presenting a paper at the rapidly approaching Emerson Exchange meeting in Nashville. He’ll be presenting a short course and two workshops, including one entitled, Coordinated Loop Tuning Saves Energy on Distillation Column. He is co-presenting this with two engineers from the Monsanto Corporation.

The project they profile is on one of their distillation columns. The team started by diagnosing the current performance of the column. They discovered by looking at uncompressed history data that there were problems with several key valves which had excessive deadbands. This caused limit cycling on the level and manipulated flow into the column. This was fixed by installing Fieldvue DVCs (digital valve controllers.)

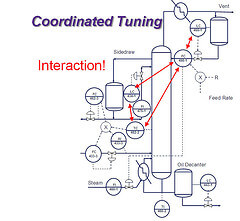

After getting better performance from the valves from the digital valve controllers, the team attacked the issue of the interactions between the loops on the distillation column. The approach taken was to set a loop tuning sequence and began manual output step tests to detect problems and measure process dynamics.

After getting better performance from the valves from the digital valve controllers, the team attacked the issue of the interactions between the loops on the distillation column. The approach taken was to set a loop tuning sequence and began manual output step tests to detect problems and measure process dynamics.

James used Emerson’s Entech Toolkit which performed high-speed, uncompressed data collection and provides an analysis of non-linearities. It also analyzed the process dynamics, calculated tuning, and performed simulations of loop response. Prior to this work each loop had been tuned independently and therefore the process dynamics were not coordinated between these loops.

By manipulating the closed loop time constant, the team was able to coordinate the speed of the loops and determine the critical tuning sequence to account for the process dynamics and loop interactions. The results from this optimized tuning were a 27% reduction in reflux and 5% energy savings from lower steam usage.