Moore’s Law foretold of computer processing power doubling every eighteen months when the idea was introduced by Intel’s cofounder Gordon Moore in 1965. This law has application in process automation since the microchips that power today’s controllers and I/O have taken advantage of this increasing power.

Advanced process control algorithms, once solely running in the domain of host-level computers running above the automation systems, are now available down in automation system controllers. These algorithms include model predictive control, fuzzy logic, and neural networks to name a few. The benefit is that these controllers are closer to the action of the running process and can use the diagnostic information in smart field devices to make sure they know when to control, and when to leave control in manual with the operators. These controllers are also available in redundant configurations, something that was more difficult and expensive to achieve with host computers.

Another result of this ever increasing processing power is that more applications can take advantage of these advanced process control algorithms. What was once strictly the domain of large applications like refinery optimization due to the cost, complexity and expertise required, can now be applied to smaller applications.

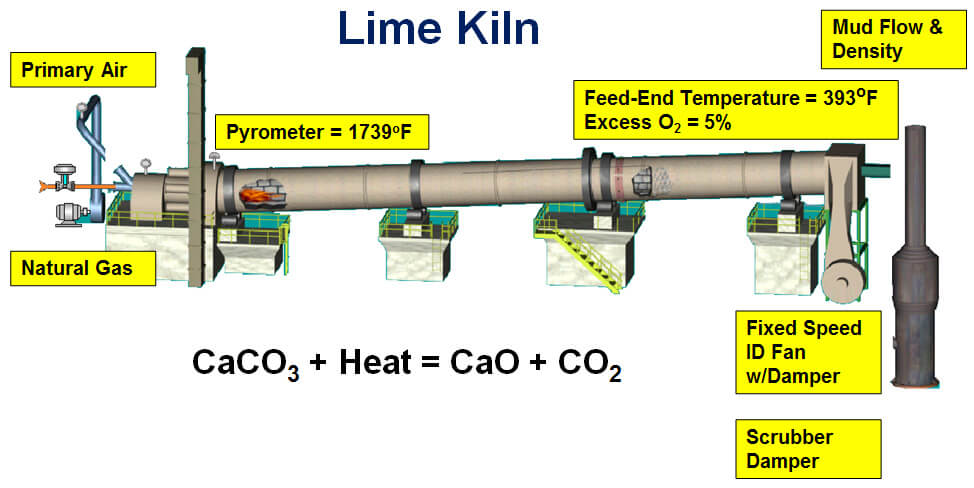

Lime kilns found in pulp and paper mills, cement and steel mills are a great example of a smaller application that is well suited for model predictive control (MPC) technology. I spoke with Gordon Lawther, a consultant in our Pulp and Paper industry center. Gordon explained that lime kilns are highly interactive in that a change to one process variable impacts the others. They are also constrained by excess oxygen, hood draft pressure, and the kiln stack emissions.

Lime kilns found in pulp and paper mills, cement and steel mills are a great example of a smaller application that is well suited for model predictive control (MPC) technology. I spoke with Gordon Lawther, a consultant in our Pulp and Paper industry center. Gordon explained that lime kilns are highly interactive in that a change to one process variable impacts the others. They are also constrained by excess oxygen, hood draft pressure, and the kiln stack emissions.

Using model predictive control allows the lime kiln to be operated as a unit instead of a collection of loops which all interact with one another. Since it’s an empirical model of the running processes it can predict into the future to help operators see where key variables are heading and help them resist manually intervening and inducing variability into the process.

Gordon noted that this increased variability is reflected in the lime quality and fuel usage which increases operating costs. The team has consistently documented annual energy savings of 10% or more and maximized mud throughput has saved more than $500,000 USD per year in purchased lime.

The team has packaged their expertise into a SmartProcess Lime application. It uses Emerson model predictive control technology and the expertise Gordon and team bring in benchmarking the existing process, creating and commissioning the models, and measuring the performance improvements. The importance of training operations staff cannot be overstated and is also an integral part of all SmartProcess Lime projects.