In today’s guest post, Emerson’s Dan Nower, a member of the Asset Optimization and Metals & Mining industry team, shares his thoughts on ways to combat “pinch-points” in mining operations.

In recent blog posts, we have discussed how world markets are pressuring mining companies to maximize production. The enemy of maximized production is unplanned equipment outages, especially an equipment outage at a production ‘Pinch-Point‘. A pinch point is a location in the production process, that if it were to stop, the production process is significantly reduced or is totally pinched off. Usually at the center of those potential pinch-points are assets that, if correctly monitored, can keep you from getting pinched. At a minimum, you can plan when this asset will be out of service to minimize the effect of the pinch.

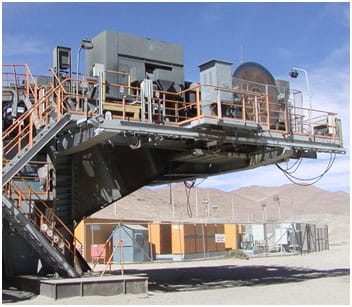

A great example of a pinch-point is a conveyor. Conveyors can be several miles in length; therefore, there will not be a duplicate conveyor to pick up the slack in production if the other is out of service. This is the only way to move product from the pit to the crushers and concentrators. When that one conveyor system is out of service, there is ZERO production coming from that portion of the mine.

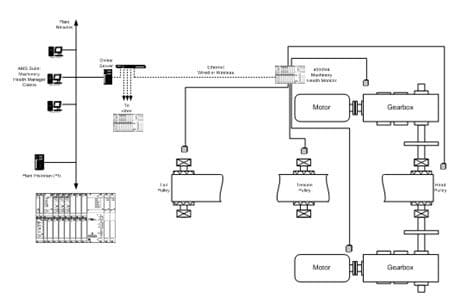

How do you avoid this situation? Monitor the critical components of the conveyor system. The use of vibration analysis to monitor the motors and gearboxes will provide machinery health information so that those responsible for these critical assets can make operational decisions based on its condition. If the health is good, don’t worry about being pinched. If the health is deteriorating, vibration analysis can provide an idea of how soon this needs to be fixed (severity) and can determine what the impending failure shall be. Therefore, an outage can be planned to be performed during a slow period, material can be on site and the correct personnel can be scheduled to be available during a non-overtime period.

For one US Molybdenum mine, a gearbox that was run to failure caused an unplanned outage. The unplanned outage of several days cost this mine millions of dollars in lost production. At that time, losses were incurred at a rate of $250,000 USD/hour for this 24/7 operation. Based upon the economic impact of this outage, the mine management team decided it was time to rethink how the conveyor was operated. They wanted to know on a continuous basis, the health of this highly critical asset. The mine decided on continuous monitoring of the primary drive motors, gearboxes, and the primary pulleys (head, tension and tail).

The moral to this story? Don’t get pinched, it hurts!