Nothing controversial this time, but Tom shared with me that he’s written a whitepaper, DeltaV pre-engineered control module templates and operator faceplates to facilitate development and use of SPM [statistical process monitoring] diagnostics originating in Rosemount pressure instruments. I gleaned from a DeltaV News item that this whitepaper is now available online.

Tom shares the outcome of applying a human-centered design approach to make advanced diagnostics from Rosemount transmitters more accessible to operators and maintenance personnel, while reducing to the effort on engineers to surface these diagnostics. The whitepaper [hyperlinks added]:

…describes how to use pre-engineered control module templates and operator faceplates to reduce engineering time and expertise needed to implement SPM diagnostics from Rosemount 3051S pressure transmitters. It further shows how operators and process engineers can use the information to prevent or more quickly address abnormal situations.

Tom offers a great recap of what SPM is and how it helps detect abnormal conditions:

Each analog process variable has process noise associated with it. A noisy process variable can lead to excess correction by the control algorithm, and excess travel by the final control element. This can degrade control, and lead to excess wear in the final control element. Traditionally, the process variable is filtered to eliminate process noise.

Process noise actually contains a great deal of information on both process and equipment performance and health. As process or equipment performance change, the noise generated by them will also change. This noise can be analyzed statistically to determine if everything is operating normally, or if abnormal process or equipment conditions exist, and can even help identify the specific type of process or equipment abnormality. It’s important to remember that abnormal conditions can exist even if the process variable is at setpoint and stable.

To reconcile the need for better control and reduced valve wear, with the need to analyze the noise before vital information is filtered away; SPM is done in the 3051S transmitter, but displayed and recorded in the DeltaV host system. The 3051S performs SPM on higher frequency noise than can be done in a host, so 3051S-based SPM and host application-based SPM are complementary.

Being able to predict plant problems to avoid safety or shutdown conditions has value that’s quickly understood. These advanced diagnostics can help uncover entrained air in liquid lines, liquid in gas lines, pump and valve cavitation, plugged impulse lines, flame instability, distillation column flooding, and more.

What’s holding back widespread use is the work required in initial engineering, SPM monitoring point configuration, and detailed engineering knowledge to design and implement an SPM monitoring strategy.

Using the HCD approach, the development team identified three primary types of users:

…first is the control systems engineer who is responsible for configuring the necessary monitoring strategies, faceplates, and historian files needed to effectively use SPM. The second user is the process engineer, reliability engineer, or quality engineer who would use the SPM information to analyze process characteristics, including both normal and abnormal conditions, and implement process improvements. The third user is the operator who would use the information in real time to improve plant reliability or performance. There are other potential users of SPM information, such as maintenance personnel.

Tom describes how the SPM engineering process is simplified with DeltaV pre-engineered templates and faceplates. The control module has:

…preconfigured and pre-linked alarm detection blocks that generate alarms based on data provided by the field devices.

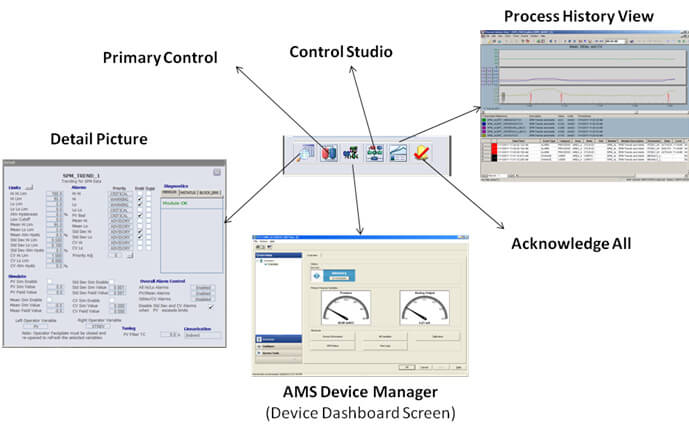

In the whitepaper, he shows the preconfigured templates and walks the reader through the steps to enable SPM and make it visible for the operators via faceplates with limit indicators and alarm condition indication. These faceplates also provide one-click access to device diagnostics, process history, and detailed device information.

In the whitepaper, he shows the preconfigured templates and walks the reader through the steps to enable SPM and make it visible for the operators via faceplates with limit indicators and alarm condition indication. These faceplates also provide one-click access to device diagnostics, process history, and detailed device information.

Tom closes the whitepaper with a “how to get started with an SPM program” section. He identifies three approaches. The first approach is to broadly turn on SPM on all pressure measurement devices and in the event of an abnormal condition, determine which SPM diagnostics may have provided early warning, and if so, set alarm limits to help prevent future situations.

The second approach is to target an application, such as plugged impulse lines, benchmark, and prove return on investment, based on plant operating history. The third approach is to identify high value assets or processes, identify possible abnormal conditions, and analyze the potential SPM signatures that could predict the abnormal conditions.

Improving technologies such as statistical process monitoring by reducing the barriers to engineer, configure, and view the diagnostics is key in having its value realized.