Emerson’s John Kuloszewski and Russ Muller shared their thoughts on what the future holds in a presentation, Digital Plant of the Future-It’s Closer than You Think. Their abstract:

HART, WirelessHART, Foundation fieldbus, Profibus. Digital automation and instrumentation technologies are enabling higher availability and reliability while driving down costs in both project execution and operations. This paper will give an overview of each including some future developments. Emphasis will be on application sweet-spots, selection criteria, and preparing your people to work with them.

The business case for digital technologies has many elements. Project costs are lowered through less infrastructure, lower installed cost, and fewer changes. During operation, process availability and reliability is increased since the devices can report their health and often the health of the surrounding process. From a maintenance perspective, some of the manual routine checks can be automated and done on a periodic basis by the device and control system. For abnormal conditions, information about the process and surrounding assets are available to the operators and maintenance personnel.

The business case for digital technologies has many elements. Project costs are lowered through less infrastructure, lower installed cost, and fewer changes. During operation, process availability and reliability is increased since the devices can report their health and often the health of the surrounding process. From a maintenance perspective, some of the manual routine checks can be automated and done on a periodic basis by the device and control system. For abnormal conditions, information about the process and surrounding assets are available to the operators and maintenance personnel.

Digital buses, wireless technologies, and wires are enabling technologies; they are not the solution. When selecting the appropriate technology some questions to consider include mix of analog and digital I/O, mix of smart microprocessor-based devices versus “dumb” parts that provide I/O but no accompanying diagnostics. I/O mix for control versus safety, existing bus field devices, and installation distances.

More considerations include hazardous locations, availability requirements, diagnostic requirements, synchronized communication considerations, functional safety considerations, support for intelligent device management, appropriate performance for task, local support and device availability, and interoperability testing conformance and compliance.

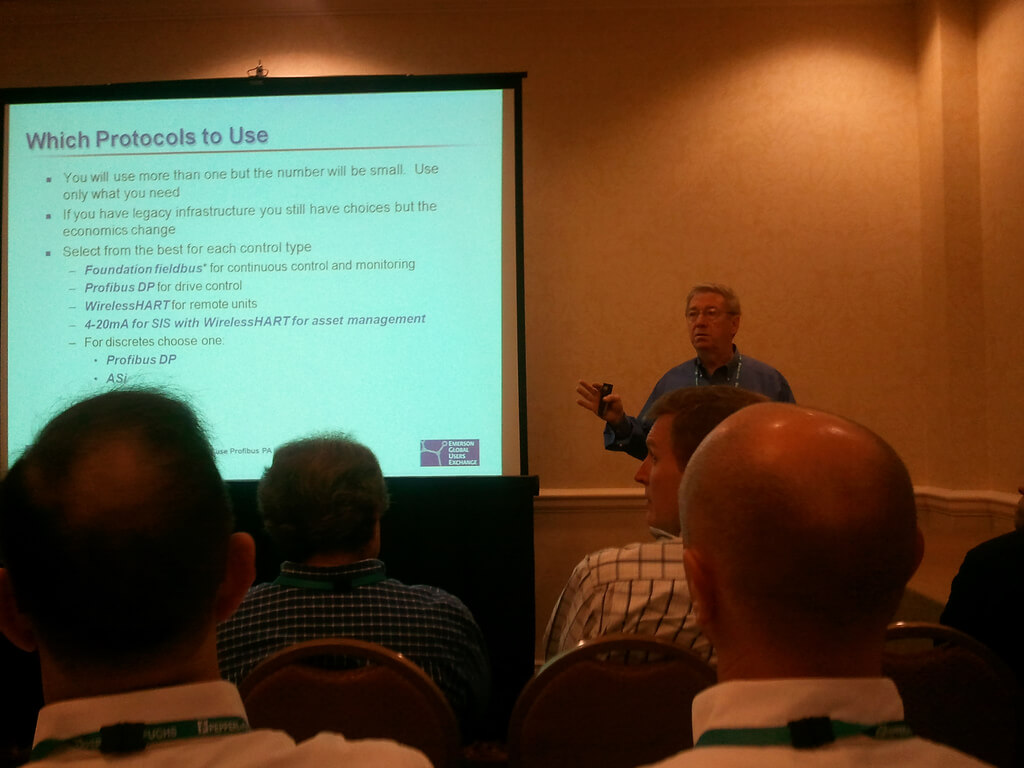

Russ shared some of the communications technology available including Foundation fieldbus, Profibus DP, WirelessHART, and 4-20mA for SIS with WirelessHART for asset management. For discrete I/O choices typically include Profibus DP, ASi, and DeviceNet.

Russ described how Foundation fieldbus can truly distribute control into transmitters and final elements such as valve controllers. The digital signals provide more accurate information than analog devices. The capacity scales in size, status comes along with the process variables, and information extends well beyond process variables to include diagnostic, configuration, and calibration information.

Russ shared things you need to do to go digital. Training is top of this list. Digital communications is different than analog. What you don’t know can bite you. Start the training with your newest folks since they don’t have to unlearn the old ways. Be open to adjusting your work practices. Who does what may change and the manual checks can stop since the bus communicates back to you.

John discussed WirelessHART in its ability to go where its difficult or not possible to pull wires. Training is also good to shortcut the learning curve and get comfortable with the capabilities and best practices with the technology. Much like the other digital communications, it important to be open to modifying existing work practices and roles required.