At the ARC Industry Forum this week in Orlando, Ergon‘s Steve Elwart shared how they have taken a systematic approach in managing alarms at the refinery to reduce unplanned downtime, avoid equipment failure, and improve operator performance. He opened with an incident surrounding a fired heater unit. Due to a flood of alarms, high tube skin temperature alarms were missed, resulting in equipment damage and degraded operations.

From this incident and other ones from other refineries, a cross-functional team was assembled to look at the existing alarm performance and overall alarm design and to make required changes. The team quickly discovered plenty of room for improvement. Alarms were occurring that needed no operator action. These were ripe for elimination. For other alarms, if action was required, they wanted to clearly convey to the operator what actions to take.

The team looked at the history logs surrounding unit upsets to see the flood of alarm patterns that were present. The also looked alarms that remained active for extended periods of time—even when nothing was wrong in the process. There was no procedure in place for adding, removing, or changing alarms.

Given the current state, the team evaluated the impact of better alarm management. Maintenance costs would be reduced from avoidance of equipment damage. Reducing the 3-5% capacity loss through process upset avoidance and more rapid recovery would be possible. Better alarm management would also mean improved safety and environmental compliance and overall operator effectiveness.

Steve highlighted an AIChE study on the time between an alarm and the diagnosis of an abnormal event. If the time was a minute or less for the operator to respond to the alarm, the probability of the abnormal event occurring approached 100%. If the operator had 10 minutes of warning, the likelihood of heading off the abnormal event was 50%. 20 minutes—10% probability, 30 minutes-1% probability. So it was important to remove the nuisance alarms and design the alarm points to give ample warning to give the operators time to resolve the situation and avoid the abnormal situation.

The team looked at the EEMUA-191 alarm systems standards for alarm management best practices. They used the DeltaV Analyze software to help identify the problem alarm areas.

The team looked at the EEMUA-191 alarm systems standards for alarm management best practices. They used the DeltaV Analyze software to help identify the problem alarm areas.

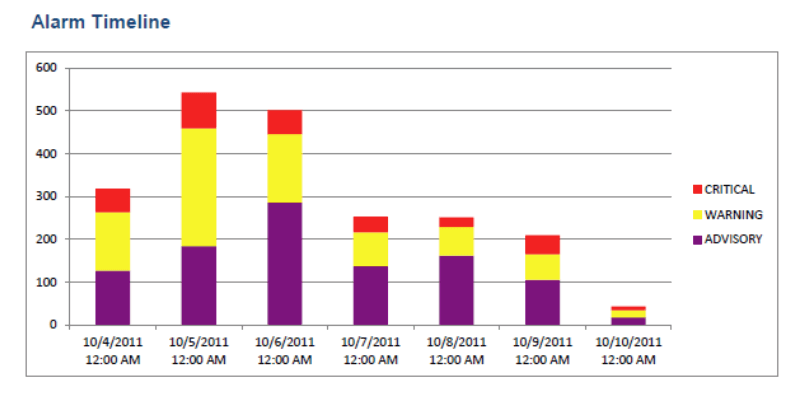

The charts generated by the software also were used with the plant staff to keep the visibility of the improvement program high and the staff engaged and focused on the effort.

Steve summed up their systematic approach to improved alarm management. First, benchmark existing conditions. Next, establish a philosophy for the alarm strategy. Next, choose the variables to alarm. Then, set limits and priorities. And with each alarm, develop recommended operator actions. The team’s work and feedback to Emerson also led to improvements in the DeltaV system as it applies to capturing and displaying recommendation operator actions.

The resolution steps continued with reviewing and applying advanced alarm techniques such as grouping and dynamic alarms based upon process states. Adding condition monitoring was next. The alarm strategy was documented and incorporated into existing change management processes. The alarm performance was periodically audited and key performance indicators used to provide ongoing visibility.

For others needing to improve the management of their alarms, Steve highlighted the need for a multi-function team to bring perspectives and organizational support for the time, energy, and funds required in the improvement process. Start by identifying and eliminating the alarm “bad actors” first. Eliminate any duplicate alarms. Design specific strategies to eliminate and avoid alarm flood conditions. Training both for the assessment phase and operator use is critical. Most of all, keep moving forward. It’s easy to lose focus among other competing priorities.

Steve closed by recommending that you establish a timeframe and objectives. Conduct training using a consultant to develop in-house expertise and capability. And, consider the use of software to aid in the analysis and reporting required for the improvement effort.

In the panel session, ARC’s Dave Woll shared a comment he heard from a process manufacturer that may spur you on in this improvement journey, “When your alarms are out of control, your plant is out of control.”