Few things wreck a good day at the plant, mill, platform, wellpad, or other process like a bearing failure on an important pump, compressor, fan, or other piece of rotating machinery. Identifying the problem early before it leads to an unplanned shutdown means the work to fix it can be scheduled to minimize operational impacts.

In earlier posts, such as Spotting Bearing Failure in Time before Complete Fan Failure, we highlighted the unique PeakVue (peak value analysis) methodology to detect early problems with bearings before they lead to a bad day. This diagnostic tool is useful for bearing defect detection in applications where normal spectral analysis has proven to be ineffective—large gearboxes, slow speed machinery, etc.

Through the magic of a succinct, 3-minute YouTube video, PeakVue InfoGraphic Animation, here is an overview explaining PeakVue measurements of stress waves on a typical plant asset through the stages of bearing failure.

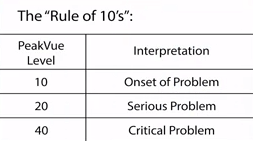

Bearings with no problems should have a PeakVue value close to 0. The video shares a simple “rule of 10’s” guideline that highlights the stages of bearing failure—onset of problems (10g’s), serious problem (20g’s), critical problem (40g’s). This progression may occur over weeks or even months, but once it advances past 40g’s, a failure is likely to be imminent.

Bearings with no problems should have a PeakVue value close to 0. The video shares a simple “rule of 10’s” guideline that highlights the stages of bearing failure—onset of problems (10g’s), serious problem (20g’s), critical problem (40g’s). This progression may occur over weeks or even months, but once it advances past 40g’s, a failure is likely to be imminent.

This PeakVue measurement is available in the vibration analysis products including the CSI 2140 portable analyzer, the CSI 9420 wireless vibration transmitter, and the CSI 6500 machinery health monitor.

You can connect and interact with other reliability and machinery health professionals by joining in the Asset Optimization, Maintenance and Reliability track of the Emerson Exchange 365 community.