Smart field devices based on HART, Foundation fieldbus, and Profibus had standards-based files to integrate them with control and asset management systems. The file types, EDD and DTM were not compatible with one another causing process manufacturers and automation suppliers to grapple with both. Field Device Integration (FDI) provides a common approach for managing information within intelligent field devices for the tasks associated with them, from configuration, commissioning, and diagnostics to calibration.

At last fall’s ISA Automation Week conference, Emerson’s Jonas Berge and Terry Blevins, the Fieldbus Foundation’s Stephen Mitschke, and Siemens’ Ludwig Winkel presented the paper, FDI Meets Plant’s Device Integration Needs.

At last fall’s ISA Automation Week conference, Emerson’s Jonas Berge and Terry Blevins, the Fieldbus Foundation’s Stephen Mitschke, and Siemens’ Ludwig Winkel presented the paper, FDI Meets Plant’s Device Integration Needs.

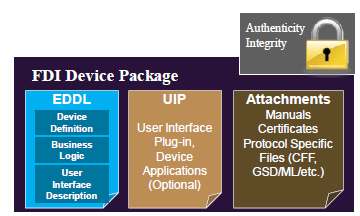

They highlight the core, enabling technologies that include the FDI Device Package and the Common Host Components.

At the base of FDI is the electronic device description language (EDDL). The device package contains an EDDL file and optionally a plug-in and other integration files such as a PROFIBUS GSD file or Foundation fieldbus CFF file. Other files can include useful information such as user manuals.

At the base of FDI is the electronic device description language (EDDL). The device package contains an EDDL file and optionally a plug-in and other integration files such as a PROFIBUS GSD file or Foundation fieldbus CFF file. Other files can include useful information such as user manuals.

The authors note the conceptual similarities between the FDI packages and HTML and XML in that they are text based, and independent of operating system flavor and version. Investments in systems are protected because the operating system does not need to be updated and new FDI packages do not render the system obsolete.

From a robustness standpoint, FDI packages do not overwrite system files or make entries into the operating system registry area. Given that these text files do not interfere with other software, they can be loaded on the automation system itself to integrate smart device management with the operator and maintenance workstations.

From a system administration perspective, existing and future intelligent devices can be easily integrated into systems. Each version of a device has its own FDI package ensuring that multiple versions can coexist without conflict. License keys are not required for the EDDL portion of the FDI package to help simplify and streamline system administration.

FDI provides a common technology for the smart field devices and the systems to which they connect. The device suppliers create FDI packages providing step-by-step guidance for setup, calibration, diagnostics, and other forms of assistance. Complex procedures can be wrapped in wizards to simplify the execution of the procedure.

From a usability standpoint, the content and structure of device parameters, trend charts, waveform graphs, and wizards are organized in system displays for use by the control and asset management systems. The rendering of the graphics is done by the system, which provides a common look and feel for all the devices connected to it.

Take a look at the whitepaper for descriptions on how interoperability registration works and migration from EDDL and FDT-based systems. The authors conclude:

FDI technology provides a single common device package for device integration on any system. Thanks to the base EDD technology, the FDI solution meets plant needs such as investment protection, robustness, easy system administration, easy to use devices, and interoperability. Moreover, existing systems can easily be migrated to FDI technology. FDT Group, Fieldbus Foundation, HART Communications Foundation, PROFIBUS & PROFINET International and the OPC Foundation have been working aggressively to develop the FDI specification. Migration to FDI should be in the long-term plans of any plant.