One of the most basic functions in an oil and gas production process is the separation of the oil, gas, basic sediment, and water. The production separator handles this function. This separation step in the process allows the flow or production rate of the individual component streams to be measured, providing essential information on the quantity of fluids produced from each well in the field.

The challenge for oil & gas operators is to perform this separation while minimizing production allocation errors, maximizing separation efficiency, and reducing gas sent to tanks and flare.

Michael Machuca

Upstream O&G Industry Marketing Manager

In this webinar, Michael highlights many of the common issues in operating separators and heater treaters including causes and their impact on the process.

In this webinar, Michael highlights many of the common issues in operating separators and heater treaters including causes and their impact on the process.

For onshore well pad sites, the measurements taken after the separation has taken place are used to pay royalties to landowners. There are legal risks when measurements don’t match what is in the tank. Poor separation can cause lost gas to sales and frequent trips by personnel to the well pad site. And, without good data, it’s difficult to make production management decisions to optimize production levels.

Michael shares some examples and financial impacts of potential problems including increased separator backpressure deferring production, produced sand eroding flowmeters, and excessive flaring caused by separator carryunder.

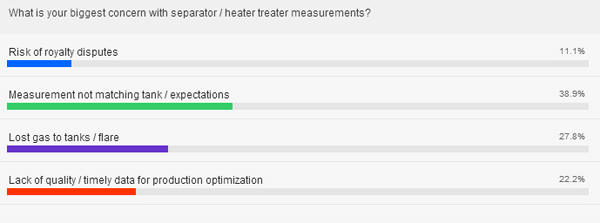

Here’s the result of a poll question he asked on the biggest concern around separator and heater treater measurements:

As you watch the recorded webinar, you can provide your answers and see updated results.

Watch the webinar for solutions to causes of poor performance including unreliable pressure control, poor dump cycle control, flow measurement errors, level control problems, well test management errors, sand accumulation and poor temperature control.

Other recordings in the well pad automation webinar series include:

- Best Practices for Well Pad Automation

- On the Level about Better Tank Management

- Optimizing Wellpad Custody Transfer of Liquid Hydrocarbons

- Improving the Safety and Efficiency of Your Drilling Operations with Better Measurements

You can also connect and interact with other oil & gas professionals in the Oil & Gas group in the Emerson Exchange 365 community.