Douglas Morris

Power and Mining Industries Sr. Manager

A while back, I wrote about using advanced control techniques to reduce steam temperature swings which can lead to boiler unavailability. Control improvements are one method to address this problem, but so is evaluating the mechanicals in the reheat and superheat sections of a plant.

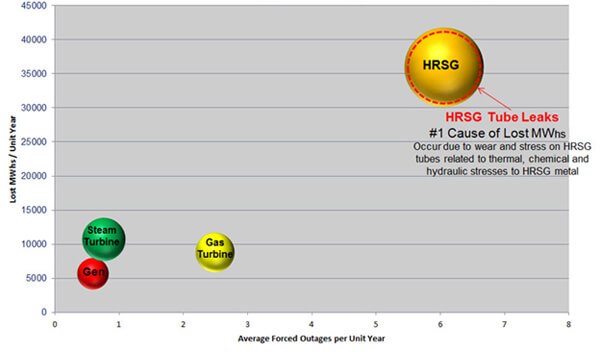

Taking a closer look at outage data from NERC’s Generating Availability Data System (GADS), tube leaks tops the cause list for lost generation in a combined cycle plant.

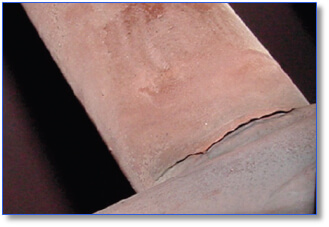

Reheat and superheat temperature variability stresses tubes and leads to metal fatigue which eventually will cause an outage. Following are some examples of failures caused by improper superheating.

Cold reheat line and tube cracks

Cold reheat line and tube cracks

This is an expensive problem as the average outage is about four days and the cost can get into a couple million dollars. From a mechanical perspective, nozzle clogging is the primary culprit. Clogged nozzles result in poor spray patterns and cause temperature swings.

Utilities have a lot to gain by implementing industry best practice which recommend the use of strainers upstream of the spraywater control valve and to replace nozzles every 18-36 months. Emerson can help with a number of attemperator solutions.

In today’s tough financial environment where utilities are looking for ways to improve their operations, why not look at your steam mechanicals? You could be in line to save a couple of million dollars.