Competition in the bunker business

It’s clear that the bunker supply business is very competitive. Bunker suppliers have only a few terminals to choose from when sourcing the fuel and the customers who are suffering from their own challenges negotiate aggressively to win the lowest price. With very little opportunity to differentiate fuel from their competitors, since it all comes from the same few terminals, bunker suppliers resort to alternative business models to make up the profits. These options come with large risk or significant cost increases, or both. Some provide financing for their customers; however, this is often met with peril as customers file for bankruptcy and delay payment for bunkers delivered, so the ability to carefully evaluate the creditworthiness of customers becomes essential. Some suppliers invest in sophisticated trading departments to reduce risk through hedging which adds additional cost to an already low margin business. There are a few examples of suppliers who have been successful in differentiating their services. Prime examples are the customers who use mass flow measurement to provide their customers with an accurate report of the quantity delivered. These suppliers have shown that bunkering faster and more accurately is something that their customers are willing to pay a premium for, and also that time saved from conducting sounding measurements enables them to deliver more fuel to more customers and increased sales. Emerson has helped customers like these and is working with both suppliers and receiving vessels to install custody transfer systems based on mass flow measurement.

It’s clear that the bunker supply business is very competitive. Bunker suppliers have only a few terminals to choose from when sourcing the fuel and the customers who are suffering from their own challenges negotiate aggressively to win the lowest price. With very little opportunity to differentiate fuel from their competitors, since it all comes from the same few terminals, bunker suppliers resort to alternative business models to make up the profits. These options come with large risk or significant cost increases, or both. Some provide financing for their customers; however, this is often met with peril as customers file for bankruptcy and delay payment for bunkers delivered, so the ability to carefully evaluate the creditworthiness of customers becomes essential. Some suppliers invest in sophisticated trading departments to reduce risk through hedging which adds additional cost to an already low margin business. There are a few examples of suppliers who have been successful in differentiating their services. Prime examples are the customers who use mass flow measurement to provide their customers with an accurate report of the quantity delivered. These suppliers have shown that bunkering faster and more accurately is something that their customers are willing to pay a premium for, and also that time saved from conducting sounding measurements enables them to deliver more fuel to more customers and increased sales. Emerson has helped customers like these and is working with both suppliers and receiving vessels to install custody transfer systems based on mass flow measurement.

How mass flow measurement can help

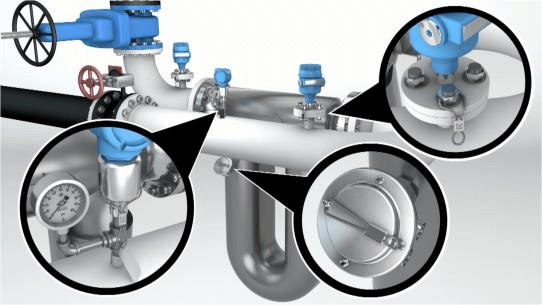

Micro Motion Coriolis technology is the heart of the Emerson’s Certified Bunker Measurement Solution. The technology uses the Coriolis force to make a direct mass measurement of quantity delivered during bunkering. This measurement is robust and is certified to provide accurate measurement during periods of aeration like stripping at the beginning and end of the bunkering. The measurement system prints a receipt after the bunkering is complete to provide both parties a record of the quantity delivered. This gives buyers and suppliers confidence and eliminates the need for post bunker negotiation.

Is the meter measurement accurate?

Mass flowmeters are accurate if used properly. Emerson has worked with customers to outline the best procedures for accurate measurement. As was clearly stated at SIBCON two years ago, the meter is not “plug and play”, and crews of both the supply and delivery vessel must inspect the installation to make sure nothing has been modified.

The critical components are all sealed by an Emerson engineer during the startup to achieve certification. Finally, the data from the bunkering is displayed in real-time on the Bunker Link software enabling the crew to monitor the delivery for any concerns and take action before the end of the delivery.

When will my supplier have a mass flowmeter?

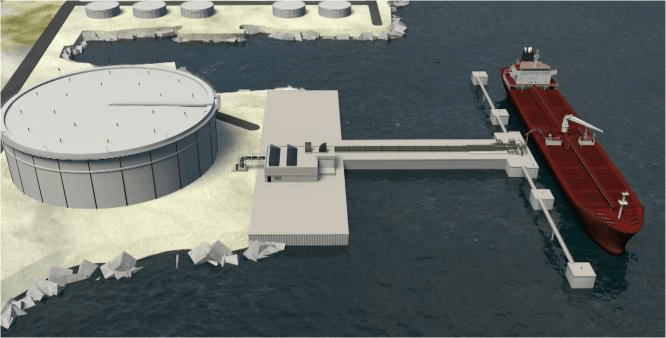

While many suppliers are using this technology to deliver fuel to their customers, adoption takes time. The Singapore Port Authority announced recently that mass flowmeters would be mandatory for all new suppliers in 2015 and by 2017 all suppliers would be required to use mass flowmeters. The best thing to do is install a meter onboard the receiving vessel so there is a certified measurement of quantity delivered. This measurement can be used to check the barge measurement and confirm the quantity delivered is accurate. Even when the supplier has a mass flowmeter that is used for billing, this meter can be used to check the barge measurement and as a backup in case of a failure with the barge measurement. For large custody transfers on land and sea, a check meter is strongly advised.

Conclusion

Suppliers looking to differentiate themselves in a crowded bunker market can use mass flow measurement as an alternative to sounding. Using a transparent measurement helps build trust with customers and suppliers currently using the technology have been able to charge a premium over the rest of the market.

Mass flow measurement also protects suppliers against customers looking to unfairly pay a lower price through aggressive dispute negotiation. Forgoing the sounding process, suppliers are saving time allowing them to deliver more fuel to more vessels and boost revenue. Customers working with Emerson are able to differentiate themselves and gain an advantage over the competition.

To see a video of the bunkering process with mass flow measurement click here: https://www.youtube.com/watch?v=oBl-aJtuVUM

For more information contact us at: [email protected]