How does wireless communications compare against wired communications for process instrumentation? That was the subject of an Emerson Exchange presentation by Kenexis’ Ed Marszal and Emerson’s Gary Hawkins. Their presentation, Risk analysis of wired versus wireless transmission of process measurements was recently narrated by Ed as an encore presentation and uploaded to YouTube.

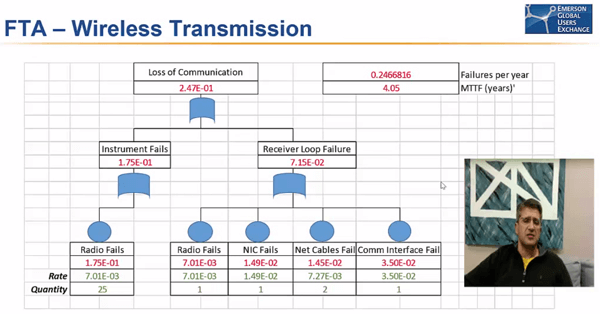

In this 30:31 video, Emerson Exchange 2014 Wired V Wireless, he discusses the strengths and limitations of using wireless communications for both basic process control and safety. He presents a typical fault tree analysis comparing the communication types along with case studies where wireless communications have been used successfully.

Ed opened some of the common perceptions among instrumentation and automation professionals who believe that wireless is not as reliable as wired transmission and not suitable for critical, safety-related services. Both perceptions he noted are not necessarily true. Nothing in the IEC 61508 and IEC 61511 global safety standards preclude the use of wireless devices. The risks must be accessed like every other component in the safety instrumented function for the SIL levels to be achieved.

He described tools that are used in risk analysis. Some, like layer of protection analysis (LOPA), are semi-quantitative and look at order of magnitude jumps in risk. Another qualitative tool that has been used for many years are probability versus severity matrices.

Beyond qualitative analysis is quantitative analysis. Simplified fault tree analysis can be used to provide different levels of accuracy and precision to the analysis to be performed. Outcomes of the analysis can be expected to differ from site to site due to differences in the sites.

At 5:35 of the video, Ed provides a general description of fault tree analysis and 7:20 he describes the safety nomenclature used for the wired vs. wireless risk analysis. This analysis begins at 10:45 looking at a fault tree analysis for wired transmission of instrumentation information. At 14:50 the wireless transmission analysis begins.

Ed provides some cases where a wireless solution was the preferable one. They involving timing to get installed, the speed of the process (process safety time), quicker recovery from an accident, and providing redundant routes (one wired, one wireless).

Take a look at the video to better understand how the fault tree analysis is performed for wired and wireless communications. You can also connect and interact with other safety professionals in the Safety Instrumented Systems group in the Emerson Exchange 365 community.