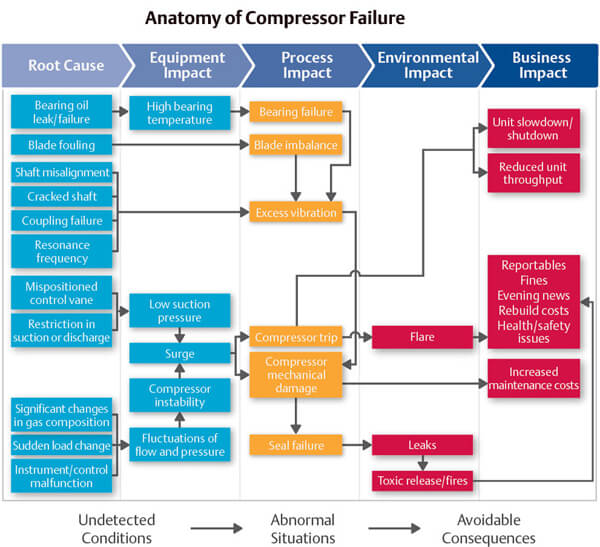

Compressors are important assets for most process manufacturers and producers. Common threats to their health include high vibration, fluctuations in gas flow, surge conditions, suction or discharge restrictions, temperature spikes, seal failures and inadequate lubrication.

In this 3:50 YouTube video, Video Tutorial for Emerson’s Essential Asset Monitoring Software – Compressor Monitoring Module, Emerson’s Jordan Rogers demonstrates how second-tier equipment, also referred to as essential assets, includes pumps, heat exchangers, blowers, non-critical compressors, pipes and vessels, cooling towers, and air cooled heat exchangers. Compressor failures and shutdowns can cause production losses of up to 0.6 % and each additional 10 psi equates to a five percent increase in the cost of power.She opens the video show the home page overview of the AMS Suite: Asset Graphics display. From the overview, she navigates to a detailed view of a 3-stage, fixed-speed and fixed-vane compressor. Parameters displayed include information about the speed, energy usage, lube oil status, bearing temperatures, vibration and process values (pressures, temperatures and flows) across each of the three stages.

Jordan next shows how trends are easily built based on the real-time parameter values. She demonstrates an alert caused by the standard deviation of the discharge pressure, which indicates instability of the process flow. This alert is available for the operations and maintenance staff to investigate to help avoid an unplanned shutdown.

More information is available on the Compressor Health Monitoring page.

You can connect and interact with other reliability and maintenance experts in the Reliability & Maintenance group in the Emerson Exchange 365 community.