Emerson’s Ronnie Bains presented A path to Operational Excellence: Multi-Purpose Dynamic Simulation with 3D Immersive Technology at the Emerson Exchange conference in Denver. His abstract:

Dynamic Simulation has evolved over recent years. This has enabled simulation technology and Multi-Purpose Dynamic Simulator (MPDS) to be applied widely. The next generation of simulation uses 3D immersive technology integrated into the core MPDS of the process. This enables the view of the external operator to be simulated with that of the control room operator, creating a unique platform to support integrated operations. This presentation outlines how the MPDS of a process can be used for different activities, integrated with 3D immersive technology to achieve operational excellence.

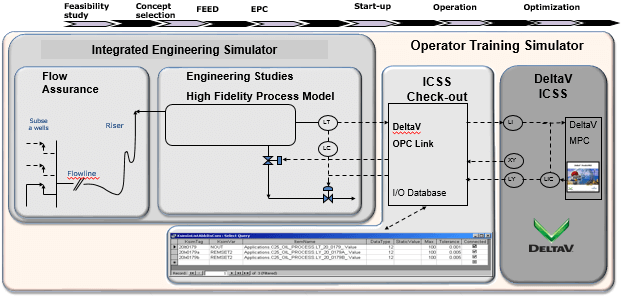

Ronnie opened noting that the application of simulation technology has evolved over recent times and it has a wide reaching impact of many areas of the process industries. High fidelity process simulation integrated into a replica integrated-control & safety system (ICSS) is the norm practiced today.

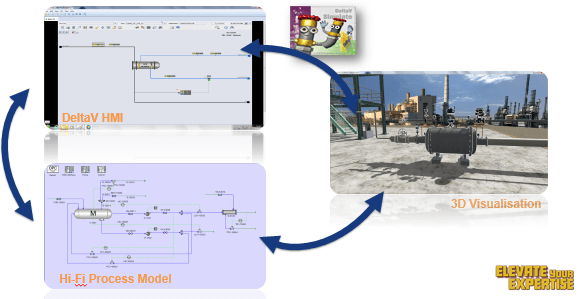

The next generation of simulation technology incorporates the use of 3D visualization technology—immersive training simulation (ITS). This use of 3D visualization provides substantial benefits in different phases of a project.

Ronnie defined a Multi-Purpose Dynamic Simulation (MPDS) as a collection of proprietary software used to build and run a simulation model that represents the dynamic operation of a process, its controls and associated logic. MPDS is the core simulation of a process, which is applied to different activities as a project.

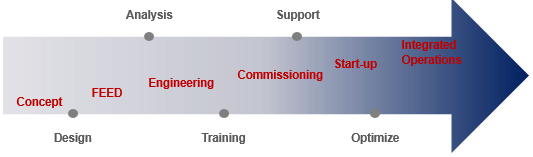

He showed a lifecycle simulation conceptual drawing:

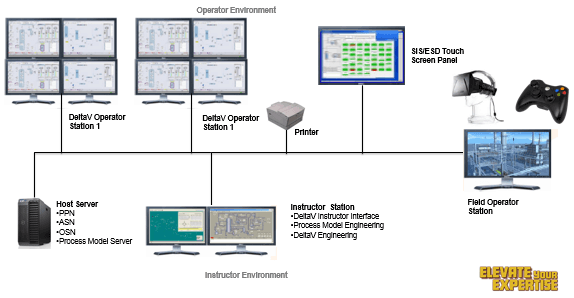

Here is an example architecture showing operating and instruction environments:

The immersive training simulation provides the realism of being in the operating environment, interacting with the process. The high-fidelity simulation, DeltaV operating environment and simulated 3D visualization of the operating environment are synchronized via OPC together in real-time:

Adding 3D visualization adds many important benefits:

- Deeper involvement of field team in understanding the process

- Plant familiarization – based upon 3D CAD model

- The full operations team can practice critical events such as start-ups, shutdowns and emergency responses in a fully realistic manner

- “Best field practices” can be designed and communicated to all staff

- Field operated devices

- Maintenance procedure verification

- Reduce travel and living costs associated with on-the-job training.

Ronnie closed the presentation with a demonstration of a simulated environment around an oil separator.