Emerson’s Mark Nixon teamed with Robert Montgomery and Bailee Roach with the University of Texas and Brian Parsonnet with Seeq on an Emerson Exchange presentation, Utilizing Predictive Analytics for Inferred Measurements. Their abstract:

The University of Texas at Austin is currently working on the design and evaluation of Divided Wall Technology (DWC). The application of DWC distillation offers the potential of significant energy and capital savings by effectively combining two distillation columns into one. Validating the operation requires accurate composition measurements from both sides of the column. Predictive Analytics can be used to provide inferred composition on-line. A system for developing and deploying models, and evaluating inferred measurement performance is described.

Robert opened describing the Separations Research Program at University of Texas in Austin. It was established at the J.J. Pickle Research Campus in Austin in 1984. This cooperative industry/university program performs fundamental research of interest to chemical, biotechnological, petroleum refining, gas processing, pharmaceutical, and food companies.

Some of the process research areas include distillation, CO2 absorption/stripping, liquid-liquid extraction, verification of separation processes, scale-up / troubleshooting and divided wall column (DWC).

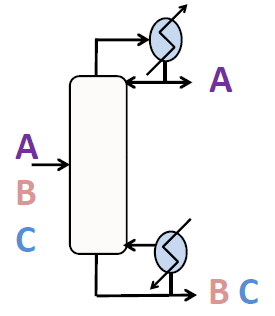

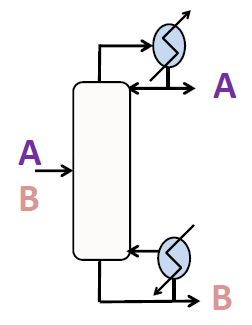

With current separations A & B components are separated out. Adding a third component requires further separation, typically on the bottoms.

With current separations A & B components are separated out. Adding a third component requires further separation, typically on the bottoms.

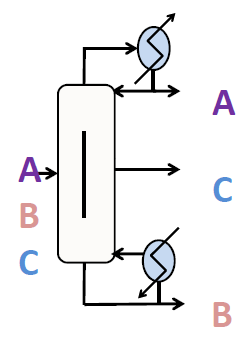

With a DWC design, it allows the third component to be separated out of the column.

With a DWC design, it allows the third component to be separated out of the column.

The focus of the project was on inferred composition.

Hydrocarbons enter into side of DWC and are separated as indicated in drawing.

Five separate samples are taken and analyzed in lab:

- Feed

- 630

- 640

- Overhead

- Bottoms

The application considered is the ternary separation of benzene, toluene, and o-xylene (BTX). DWC control design uses an inferred measurement of composition, which is based on column temperatures. For the project, the team started with 248 parameters (~8 million samples per parameter). Test data was collected in six time periods. Narrowed the sample set to 10 key parameters.

The data was loaded into Seeq and visualized using trending. The data allowed the team to discover regions of data where the plant wasn’t normal and regions where there were alarms due to temperature control problems. The team identified some nice correlations between parameters and the lab data.

Parameters that have the most impact on the operation of the column are the column pressure, temperatures, and flows.

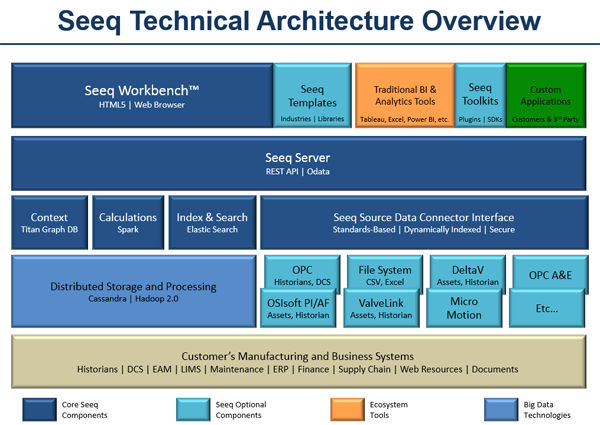

Brian showed the Seeq architecture:

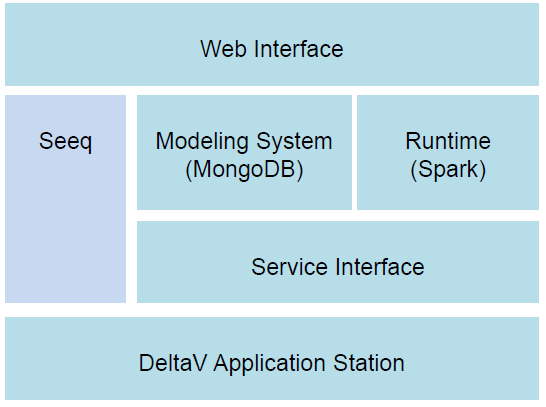

Here is a look at how it was implemented by the DeltaV technology team:

Mark closed the presentation making these key points:

- It takes several hours to return results from the lab

- Although Inferred Measurements are not a replacement for lab measurements, they provide a valuable early indication on where the process is headed

- The combined Seeq software and DeltaV system provides a nice platform to capture and explore data, develop and deploy data based models for product properties prediction, faults detection, faults identification and diagnosis.