Process measurement devices are installed where required to monitor, control, and safely shutdown the process. But often, additional measurements combined with the existing ones can help to improve several areas of process operations performance.

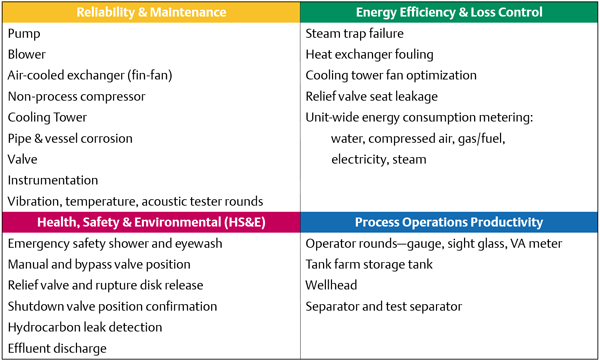

I saw a chart from Emerson’s Jonas Berge which highlighted four areas for potential improvement—reliability and maintenance, energy efficiency and loss control, health, safety & environmental (HS&E), and process operations productivity.Some applications to consider for improvement in reliability and maintenance include pumps, blowers, air-cooled exchangers (fin-fans), non-process compressors, cooling towers, corrosion monitoring on pipes and vessels, valves, instrumentation, vibration, temperature, and acoustic testing rounds.

Energy losses can happen in many areas including water, compressed air, gas & other fuels, electricity, and steam. Additional measurements can help detect steam trap failures, heat exchanger fouling, cooling tower fan issues, relief valve seat leakage, and unit-wide energy consumption abnormalities.

Although health, safety and environmental extends to people and work processes, additional measurements can assist in operating safely and in regulatory compliance. These measurement applications include emergency safety shower and eyewash station monitoring, manual and bypass valve position monitoring, relief valve and rupture disk release monitoring, shutdown valve position confirmation, hydrocarbon leak detection and effluent discharge.

For ways to increase the productivity of the process operations, Jonas listed ways to reduce operator rounds including gauge readings, sight glass measurements, and variable area (VA) flowmeters. Others areas for improvement specifically around oil and gas production and storage include tank farm storage tank level measurements, wellhead measurements, and separator and test separator measurements.

You can connect and interact with other wireless measurement experts in the Wireless group and other Measure & Analyze groups in the Emerson Exchange 365 community.