Robert Ferris, Ph.D.

Strategic Planner

As nanomaterial production increases, so does the need for quality assurance. Here, we cover the common challenges with nanomaterial scale-up and how some companies are ensuring product performance for their customers.

As nanomaterials increase production volume, there is a growing challenge in assuring product quality. This is a common, and encouraging, challenge for any material provider. Increasing production helps to reduce some fixed costs, better leverage capital, and increase the range of applications. While increasing production scale, however, product quality must be maintained to ensure customer satisfaction. Because nanomaterials is so new, however, the demand for quality is driven by customer loyalty or competitive displacement. There is little place for standards or certifications here.

Any company has tackled a quality issue as some point. During today’s production system, there is rarely a single company that takes raw materials and produces a finished product, especially inside one building. Material suppliers are only one step in a larger system focused on delivering finished products to consumers. In recent years this entire system has been focused on just-in-time delivery, reduced lead time, and best-cost production centers. As such, one quality issue or bad batch send ripples through the supply chain. We can all recall the most recent issue with the automobile airbag recall.

The need for reliable quality is persistent across nanomaterials providers as well. Nanocomposix, a high quality nanoparticle supplier, was actually started because of the founders’ trouble finding a reliable source for custom nanoparticles. In the future, we will see continued pressure on graphene or carbon nanotube suppliers; who are notorious for large variations in quality from lot-to-lot.

Some chemical industries ensure quality through testing either various material properties (such as viscosity, conductivity, or density) or process conditions during production (such as vessel temperature, or mass balance). The quality of a nanomaterial, however, is more complicated than bulk material properties. Nanomaterial performance is based on material properties that are not readily tested using bulk material methods. For example, the reactivity of a nanoparticle can depend heavily on the nanoparticle shape. Even two particles that have the same mass will perform differently. Considering you can make a ton of product a month, how do you ensure the correct shape is being produced when there is over 100 trillion nanoparticles in a single gram of material? This a difficult challenge even before considering other variables such as particle distribution, throughput rates, and contamination.

Figure 1: Image of the Cerion nanoparticle production floor. On their site, Cerion states that “…One of the biggest barriers to the widespread industry adoption of performance nanomaterials has been the inability to produce quality materials at industrial scale….”

One of the most common techniques is end product sampling. Sampling is the best way to get a clear picture of the end product performance. You can run a series of tests designed to verify performance with reasonable certainty. Sampling, however, is also recognized as the most limited form or quality assurance. Commons advantages and disadvantages are listed here. For nanomaterials in particular, sampling involves a time delay and resources need for every sample. It sometimes takes hours or days to complete all the necessary test and the specialized equipment usually requires $100 million to $1 billion dollar facility. Most material providers don’t have that kind of equipment, time, or resources. Obviously, common quality inspection techniques, such as visual inspection, also do not apply.

The challenge to nanomaterial providers is not easy to bridge. There are few standard quality control methods developed to date. Most nanomaterials have been developed using research tools not designed for rapid throughput or scalability. Common equipment, such as those sold by Oxford Instruments, can tell you a lot about the material. Almost everything you need to know. But none of them work in real-time production.

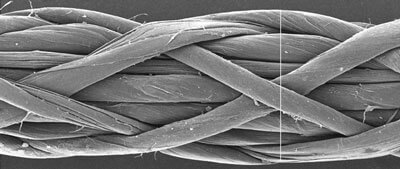

Figure 2: Imaging trying to verify the quality of woven nanotubes as demonstrated by Nanocomp Technologies. (Source: Nanowerk, Delivering on the promise – scaling carbon nanotube technology)

For some, the quality control of nanomaterials has been coined nanoanalysis, which includes special techniques for determining the atomic structures of your target material. As such, each company has to first determine the product “fingerprint,” then figure out how to reliably track that fingerprint over time. No two nanomaterials are created equal and a small change can severely impact the end performance for a customer. For example, an X-ray diffraction scan of the material may have a specific spectrum. Tracking that spectrum overtime has to be sensitive enough and reliable enough to detect material changes between batches. Even better, to detect any changes real-time. As such, every nanotechnology-enabled product is applying nanoanalysis differently.

As an alternative, some laboratories, like Balazs Nanoanalysis and NPL, offer nanoscale characterization expertise for outsourcing. Other techniques offer methods for simultaneous fabrication and inspection. Alternatively, companies can hire an internal quality control expert to establish best practices and quality metrics. This avenue has been identified by the European Centre for the Development of Vocational Training (CEDEFOP) where they identify the need to train quality assurance skilled professionals due to the high level of automation used in plants. Larger studies, such as that initiated by Prometean Particles, demonstrates the scale and resources required to instill quality control metrics at scale.

The crux of the issue is that there is not a set of production scale quality assurance equipment. Most, if not all, of the methods nonmaterial providers use are based on research-grade equipment. This means they are built to be versatile, but not scalable.

A range of techniques need to be developed that ensure quality at production scale and throughput rates. Optical and X-ray techniques currently seem to be the most promising. This is because they can function at high scan rates, over a large area, and are sensitive “enough” to nanoscale changes. The data is still an average signal across the optical window, but optics can deliver an acceptable range. Alternative surface analysis tools include scanning probe microscopy, which is versatile and easily implemented. Bruker offers a number of solutions in this space. Other methods include in situ detection methods, such as zeta potential or cyclic voltammetry. Alternatively, CORDIS is attempting to supply a multi-dimensional analysis tool or an “all in one” solution.

Nanomaterials also face a high quality bar when it comes to their customers. With bulk material suppliers, the ability to deliver the same material was critical. Nanomaterials providers instead must deliver a material that reliably performs for their customers. The difference is subtle but critical. Think back to the earlier example of different nanoparticle shapes performing differently. In this example, both nanoparticles are the same material, same size, and same weight. But one shape will deliver customer results and the other will not. There are creative ways to specify nanomaterial shape. But the point is that this is no longer the standard specifications you see with bulk material providers. In-essence nanomaterial providers are creating ways to specify customer performance guarantees. Supplier cannot simply say “we made the same stuff,” but instead they have to say “our product will act the same way for you Mr/Mrs Customer.”

“Quality is remembered long after price is forgotten…”

For now, each company needs to address these issues on a case-by-case basis. But over time the industry will catch-up with production methods and quality assurance programs. Driven by customer feedback and competitive differentiation. Remember the age-old phrase, quality is remembered long after price is forgotten; just like it did for steel and automobiles the same weighs true for nanomaterials.

Stay tuned: My next post will be about the impact of gas prices on Nanotechnology stocks.

Robert Ferris, Ph.D. is a strategic planner with Emerson Process Managements. He holds a bachelors and masters in chemical engineering, an MBA in new technology commercialization, and a Ph.D. in Mechanical Engineering and Materials Science. He has an extensive background in nanotechnology development and advanced process control.

Please, share your opinion or questions! Reply below to provide your thoughts, insights, or comments with the experts.